Search

- Page Path

- HOME > Search

Research Article

- [English]

- Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

- Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

- J Powder Mater. 2024;31(2):137-145. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00038

- 4,761 View

- 121 Download

- 6 Citations

-

Abstract

Abstract

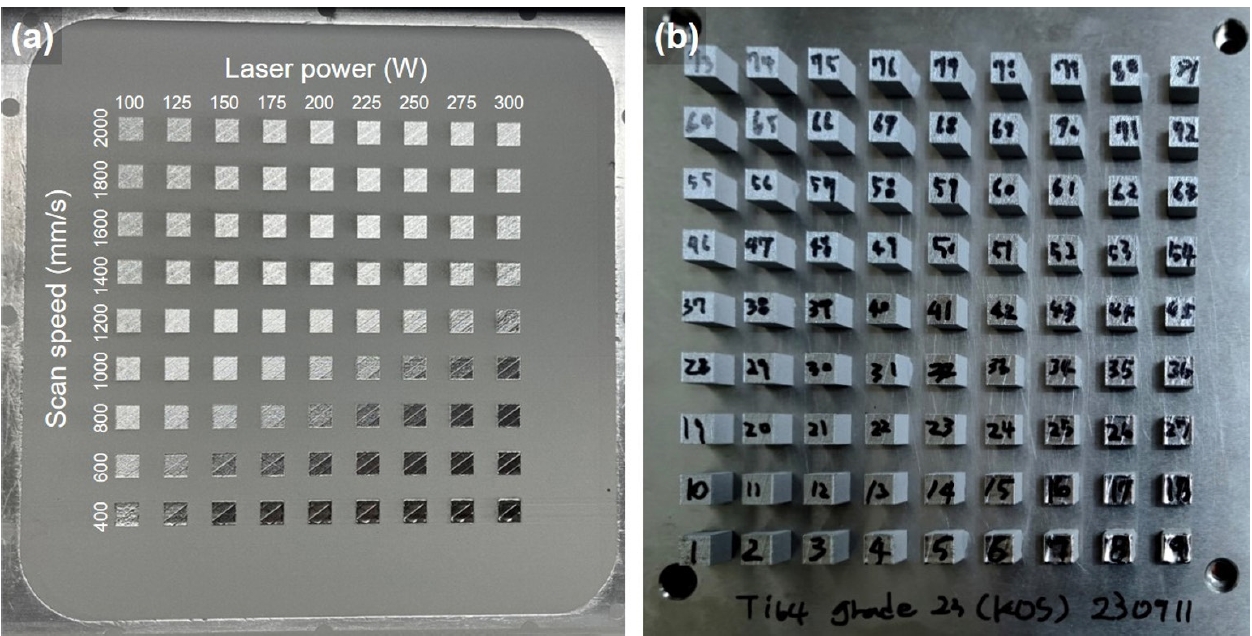

PDF

PDF - In order to predict the process window of laser powder bed fusion (LPBF) for printing metallic components, the calculation of volumetric energy density (VED) has been widely calculated for controlling process parameters. However, because it is assumed that the process parameters contribute equally to heat input, the VED still has limitation for predicting the process window of LPBF-processed materials. In this study, an explainable machine learning (xML) approach was adopted to predict and understand the contribution of each process parameter to defect evolution in Ti alloys in the LPBF process. Various ML models were trained, and the Shapley additive explanation method was adopted to quantify the importance of each process parameter. This study can offer effective guidelines for fine-tuning process parameters to fabricate high-quality products using LPBF.

-

Citations

Citations to this article as recorded by- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - From physics to intelligence: a review of AI-driven modeling strategies in laser direct energy deposition additive manufacturing

Seyedeh Fatemeh Nabavi, Saeid Nahavandi, Hamid Garmestani

Optics & Laser Technology.2026; 199: 114946. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Automated segmentation and analysis of microscopy images of laser powder bed fusion melt tracks

Aagam Shah, Reimar Weissbach, David A. Griggs, A. John Hart, Elif Ertekin, Sameh Tawfick

Journal of Manufacturing Processes.2025; 154: 61. CrossRef - Coefficient of Thermal Expansion of AlSi10Mg, 316L Stainless Steel and Ti6Al4V Alloys Made with Laser Powder Bed Fusion

Selami Emanet, Edem Honu, Kekeli Agbewornu, Evelyn Quansah, Congyuan Zeng, Patrick Mensah

Materials.2025; 18(19): 4468. CrossRef - Adaptive slicing for increased productivity of metal laser powder bed fusion

Lars Vanmunster, Louca R. Goossens, Laurent Sergeant, Brecht Van Hooreweder, Bey Vrancken

Additive Manufacturing.2025; 112: 105000. CrossRef

- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

TOP

KPMI

KPMI

First

First Prev

Prev