Most cited

- Page Path

- HOME > Browse Articles > Most cited

From articles published in Journal of Powder Materials during the past two years (2024 ~ ).

- [Korean]

- Development of Composite-film-based Flexible Energy Harvester using Lead-free BCTZ Piezoelectric Nanomaterials

- Gwang Hyeon Kim, Hyeon Jun Park, Bitna Bae, Haksu Jang, Cheol Min Kim, Donghun Lee, Kwi-Il Park

- J Powder Mater. 2024;31(1):16-22. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.16

- 1,853 View

- 33 Download

- 10 Citations

-

Abstract

Abstract

PDF

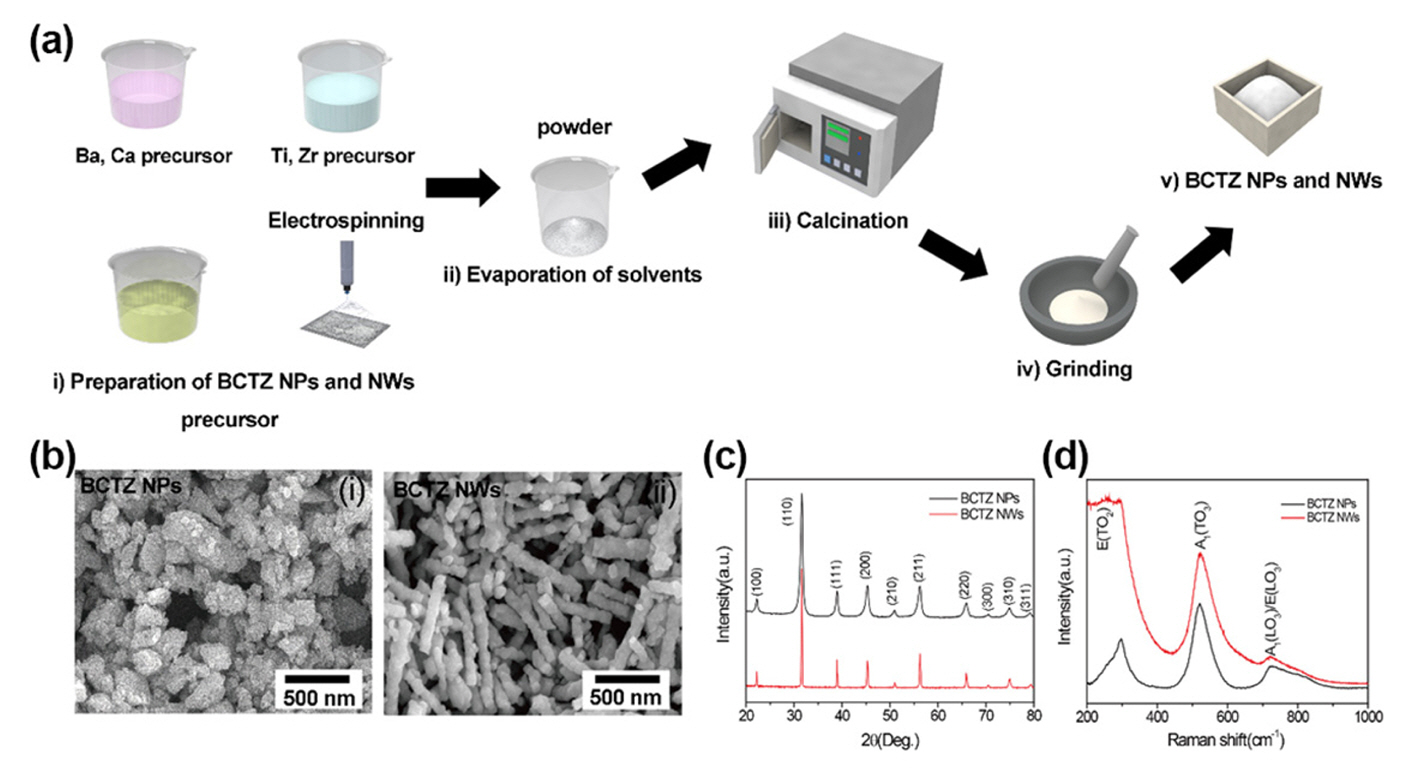

PDF - Composite-based piezoelectric devices are extensively studied to develop sustainable power supply and selfpowered devices owing to their excellent mechanical durability and output performance. In this study, we design a leadfree piezoelectric nanocomposite utilizing (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 (BCTZ) nanomaterials for realizing highly flexible energy harvesters. To improve the output performance of the devices, we incorporate porous BCTZ nanowires (NWs) into the nanoparticle (NP)-based piezoelectric nanocomposite. BCTZ NPs and NWs are synthesized through the solidstate reaction and sol-gel-based electrospinning, respectively; subsequently, they are dispersed inside a polyimide matrix. The output performance of the energy harvesters is measured using an optimized measurement system during repetitive mechanical deformation by varying the composition of the NPs and NWs. A nanocomposite-based energy harvester with 4:1 weight ratio generates the maximum open-circuit voltage and short-circuit current of 0.83 V and 0.28 A, respectively. In this study, self-powered devices are constructed with enhanced output performance by using piezoelectric energy harvesting for application in flexible and wearable devices.

-

Citations

Citations to this article as recorded by- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

HyoMin Jeon, Seo Young Yoon, Nagamalleswara Rao Alluri, Momanyi Amos Okirigiti, HakSu Jang, Changyeon Baek, Tiandong Zhang, Geon-Tae Hwang, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Sustainable Materials and Technologies.2026; 47: e01888. CrossRef - In Situ Amidation‐Derived Interfacial Modulation for Homogeneous Ultra‐High Nanoparticle Loading Toward Robust and Flexible Piezoelectric Composites

HakSu Jang, In Beom Heo, Changyeon Baek, Dong Won Jeon, Donghun Lee, Nagamalleswara Rao Alluri, Hyejeong Choi, HyoMin Jeon, SungHoon Kim, Hyunseung Kim, Jihun Choi, Hyun‐Soo Chang, Chang Kyu Jeong, Min‐Ku Lee, Jun Mo Koo, Tiandong Zhang, Geon‐Tae Hwang, S

Advanced Functional Materials.2026;[Epub] CrossRef - Long‐Lasting, Steady and Enhanced Energy Harvesting by Inserting a Conductive Layer into the Piezoelectric Polymer

HakSu Jang, Gwang Hyeon Kim, Dong Won Jeon, Hyeon Jun Park, BitNa Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Changyeon Baek, Min‐Ku Lee, Sung Beom Cho, Gyoung‐Ja Lee, Kwi‐Il Park

Advanced Functional Materials.2025;[Epub] CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Dual-controlled piezoelectric composite film with enhanced crystallinity and defect-free via solvent vapor treatment

HakSu Jang, Hyeon Jun Park, Gwang Hyeon Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, BitNa Bae, HyoMin Jeon, DongHun Lee, Kwi-Il Park

Nano Energy.2025; 136: 110705. CrossRef - Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

Journal of Powder Materials.2025; 32(1): 16. CrossRef - Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

Journal of Powder Materials.2025; 32(2): 104. CrossRef - Flexible Thermoelectric Energy Harvester with Stacked Structure of Thermoelectric Composite Films Made of PVDF and Bi2Te3-Based Particles

Da Eun Shin, Nagamalleswara Rao Alluri, Kwi-Il Park

ACS Applied Energy Materials.2024; 7(19): 8288. CrossRef - Enhanced energy harvesting of fibrous composite membranes via plasma-piezopolymer interaction

Hyeon Jun Park, Bitna Bae, HakSu Jang, Dong Yeol Hyeon, Dong Hun Lee, Gwang Hyun Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Nano Energy.2024; 131: 110299. CrossRef - CoFe2O4-BaTiO3 core-shell-embedded flexible polymer composite as an efficient magnetoelectric energy harvester

Bitna Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Jungho Ryu, Gwang Hyeon Kim, Hyeon Jun Park, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Geon-Tae Hwang, Kwi-Il Park

Materials Today Physics.2024; 48: 101567. CrossRef

- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

- [English]

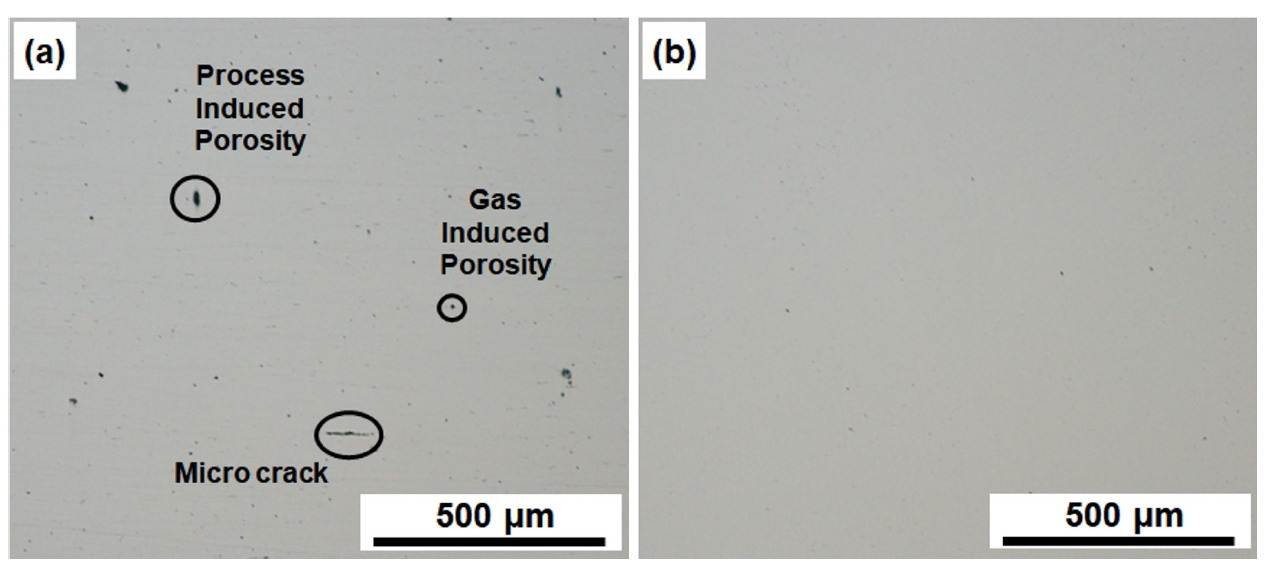

- Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

- Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

- J Powder Mater. 2024;31(1):1-7. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.1

- 6,090 View

- 134 Download

- 9 Citations

-

Abstract

Abstract

PDF

PDF This study explores the profound impact of varying oxygen content on microstructural and mechanical properties in specimens HO and LO. The higher oxygen concentration in specimen HO is found to significantly influence alpha lath sizes, resulting in a size of 0.5-1 μm, contrasting with the 1-1.5 μm size observed in specimen LO. Pore fraction, governed by oxygen concentration, is high in specimen HO, registering a value of 0.11%, whereas specimen LO exhibits a lower pore fraction (0.02%). Varied pore types in each specimen further underscore the role of oxygen concentration in shaping microstructural morphology. Despite these microstructural variations, the average hardness remains consistent at ~370 HV. This study emphasizes the pivotal role of oxygen content in influencing microstructural features, contributing to a comprehensive understanding of the intricate interplay between elemental composition and material properties.

-

Citations

Citations to this article as recorded by- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

Woo Hyeok Kim, Raj Narayan Hajra, Hyung-Ki Park, Jung-Yeul Yun, Jeoung Han Kim

Journal of Alloys and Compounds.2026; 1050: 185574. CrossRef - Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

Hadiseh Esmaeilpoor, Mahdi Aghaahmadi, Hyun Jong Yoo, Chan Woong Park, Tae Jin Jang, Seok Su Sohn, Jeoung Han Kim

Journal of Materials Science & Technology.2025; 213: 223. CrossRef - High-integrity diffusion bonding of laser powder bed fused, forged, and rolled Ti–6Al–4V alloys

Seoyeon Jeon, Hyunjong Ha, Dong Jun Lee, Hyeonil Park, Yong Nam Kwon, Hyunjoo Choi, Hyokyung Sung

Journal of Materials Research and Technology.2025; 35: 2108. CrossRef - Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Obtaining functionally-graded metal-matrix materials Ti‒6Al‒4V + WC in the process of 3D printing by the method of additive plasma-arc deposition

V. Korzhyk, A. Grynyuk, O. Babych, O. Berdnikova, Ye. Illiashenko, O. Bushma

The Paton Welding Journal.2025; 2025(8): 29. CrossRef - Obtaining functionally-graded metal-matrix materials ti‒6al‒4v + wc by the method of additive plasma-arc deposition

V.M. Korzhyk, A.A. Grynyuk, O.A. Babych, O.M. Berdnikova, Ye.V. Illiashenko, O.I. Bushma

Avtomatičeskaâ svarka (Kiev).2025; 2025(5): 48. CrossRef - Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

Journal of Powder Materials.2024; 31(5): 365. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

- [English]

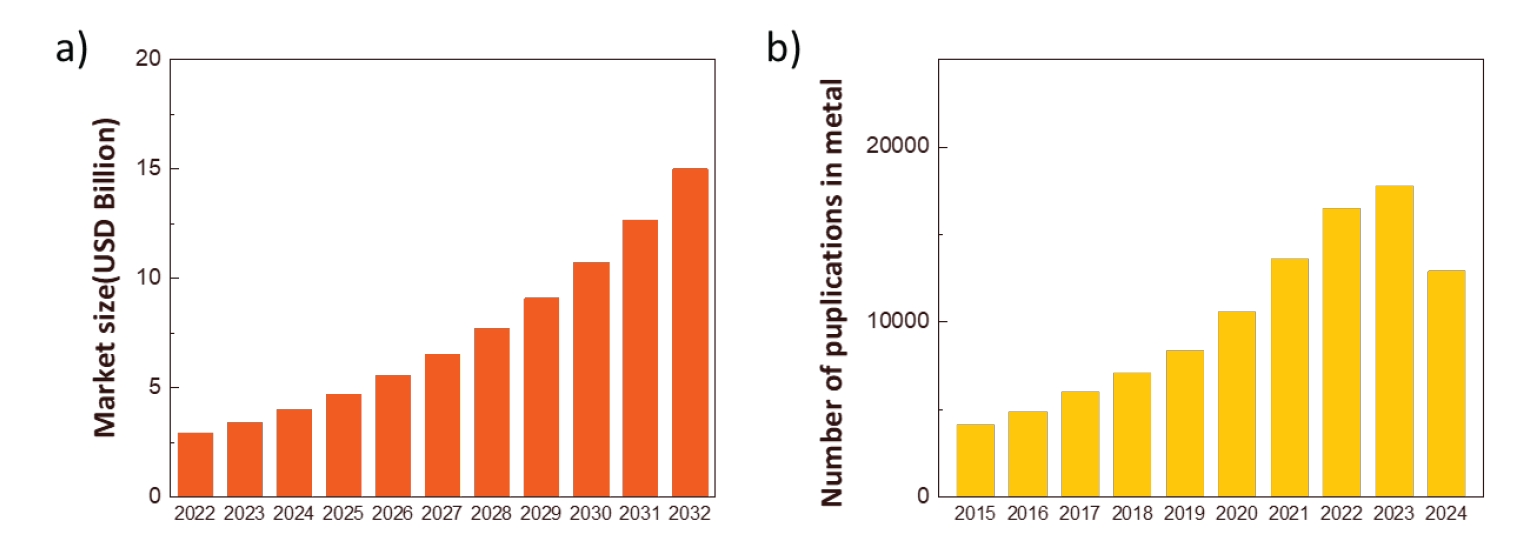

- Recent Advances in Thermoelectric Materials and Devices: Improving Power Generation Performance

- Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Kwi-Il Park

- J Powder Mater. 2025;32(1):1-15. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00395

- 9,823 View

- 217 Download

- 6 Citations

-

Abstract

Abstract

PDF

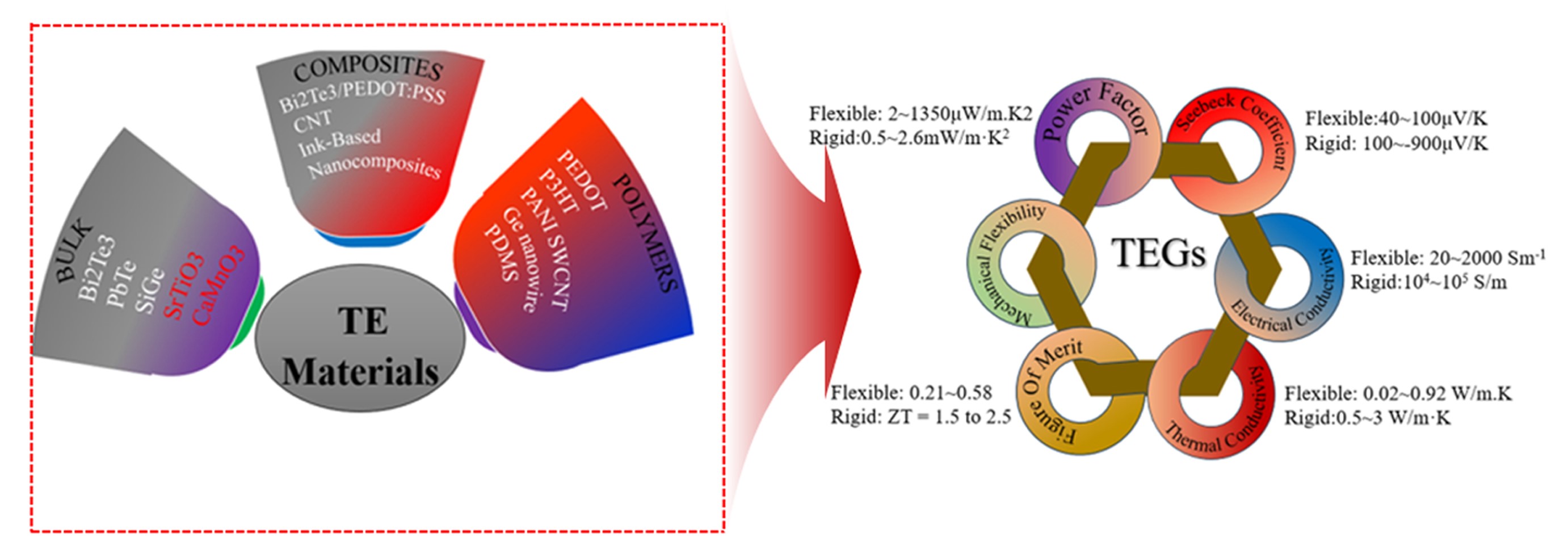

PDF - Thermoelectric materials have been the focus of extensive research interest in recent years due to their potential in clean power generation from waste heat. Their conversion efficiency is primarily reflected by the dimensionless figure of merit, with higher values indicating better performance. There is a pressing need to discover materials that increase output power and improve performance, from the material level to device fabrication. This review provides a comprehensive analysis of recent advancements, such as Bi2Te3-based nanostructures that reduce thermal conductivity while maintaining electrical conductivity, GeTe-based high entropy alloys that utilize multiple elements for improved thermoelectric properties, porous metal-organic frameworks offering tunable structures, and organic/hybrid films that present low-cost, flexible solutions. Innovations in thermoelectric generator designs, such as asymmetrical geometries, segmented modules, and flexible devices, have further contributed to increased efficiency and output power. Together, these developments are paving the way for more effective thermoelectric technologies in sustainable energy generation.

-

Citations

Citations to this article as recorded by- State-of-the-art research in conducting polymer thermoelectric composites: Design strategies, doping innovations, and emerging technologies

Vilakshana Acharya, Shivani Verma, Seema Gupta, Gaurav Pandey, Aanchal Sethi, Pooja Rawat

Journal of Applied Physics.2026;[Epub] CrossRef - Mathematical and simulation modeling of photovoltaic systems utilizing thermoelectric modules for effective thermal management

Muhammad Sohaib Tahir, Xue Dong, Muhammad Mansoor Khan

Results in Engineering.2025; 27: 106344. CrossRef - Summary of Publications in the Special Issue: Advances in Corrosion Resistant Coatings

Yong X. Gan

Coatings.2025; 15(11): 1350. CrossRef - Standard Reference Thermoelectric Modules Based on Metallic Combinations and Geometric Design

EunA Koo, Hanhwi Jang, SuDong Park, Sang Hyun Park, Sae-byul Kang

Applied Sciences.2025; 15(18): 10273. CrossRef - Research Trends in Magneto-Mechano-Electric (MME) Energy Harvesting Devices

So Ie Jeong, Geon-Tae Hwang

Journal of Powder Materials.2025; 32(6): 529. CrossRef - Transient In-Situ Identification of Thermal Parameters in Commercial Thermoelectric Modules using Transfer-Function Models

Gurum Ahmad Pauzi, Irfan Alfiansyah, Agus Riyanto, Donni Kis Apriyanto, Yanti Yulianti, Warsito Warsito

Jurnal Ilmiah Pendidikan Fisika Al-Biruni.2025; 14(2): 187. CrossRef

- State-of-the-art research in conducting polymer thermoelectric composites: Design strategies, doping innovations, and emerging technologies

- [English]

- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

- Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

- J Powder Mater. 2024;31(2):119-125. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00045

- 3,200 View

- 81 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF - The n-type Bi2-xSbxTe3 compounds have been of great interest due to its potential to achieve a high thermoelectric performance, comparable to that of p-type Bi2-xSbxTe3. However, a comprehensive understanding on the thermoelectric properties remains lacking. Here, we investigate the thermoelectric transport properties and band characteristics of n-type Bi2-xSbxTe3 (x = 0.1 – 1.1) based on experimental and theoretical considerations. We find that the higher power factor at lower Sb content results from the optimized balance between the density of state effective mass and nondegenerate mobility. Additionally, a higher carrier concentration at lower x suppresses bipolar conduction, thereby reducing thermal conductivity at elevated temperatures. Consequently, the highest zT of ~ 0.5 is observed at 450 K for x = 0.1 and, according to the single parabolic band model, it could be further improved by ~70 % through carrier concentration tuning.

-

Citations

Citations to this article as recorded by- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef - Enhanced energy harvesting performance of bendable thermoelectric generator enabled by trapezoidal-shaped legs

Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Journal of Power Sources.2025; 631: 236254. CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Enhanced Electrical Properties of 3D Printed Bi2Te3-Based Thermoelectric Materials via Hot Isostatic Pressing

Seungki Jo

Ceramist.2025; 28(1): 126. CrossRef - Hot isostatic pressing-driven fine-tuning of electrical properties in p- and n-type (Bi,Sb)2Te3 thermoelectric materials

Seungki Jo, Jeong Min Park, Linh Ba Vu, Haeum Park, Soo Ho Jung, Jinhee Bae, Jong Min Park, Jungho Choe, Kyung Tae Kim

Ceramics International.2025; 51(26): 51107. CrossRef - Compensation of increased carrier concentration and thermal conductivity in enhancing thermoelectric efficiency in Sn-doped Sb-In-Te alloys

Yunjae Kim, Seungwoo Ha, Gyujin Chang, Gwan Hyeong Lee, Jaewoo Park, Chanwoo Ju, Se Yun Kim, TaeWan Kim, Sang-il Kim

Journal of the Korean Ceramic Society.2025;[Epub] CrossRef

- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

- [English]

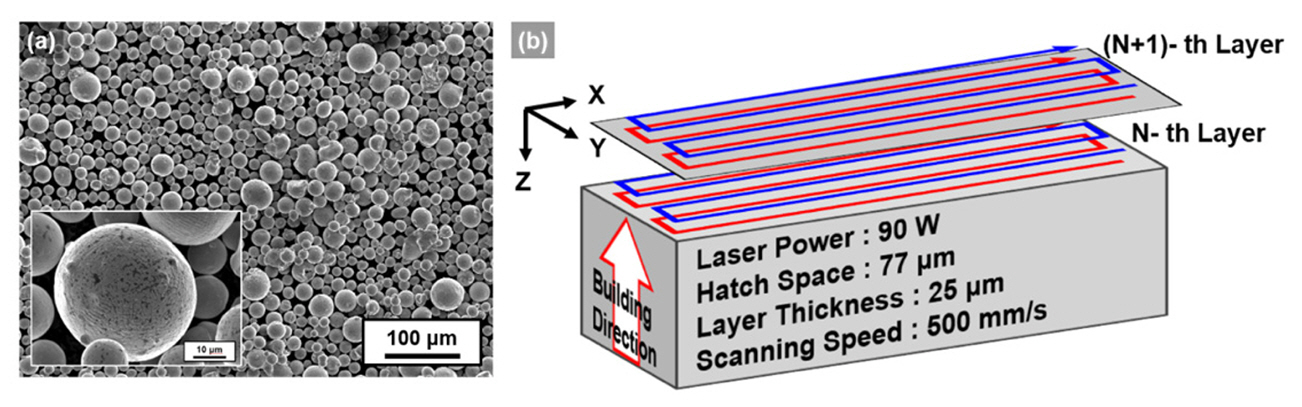

- Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

- Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

- J Powder Mater. 2024;31(2):137-145. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00038

- 4,753 View

- 120 Download

- 6 Citations

-

Abstract

Abstract

PDF

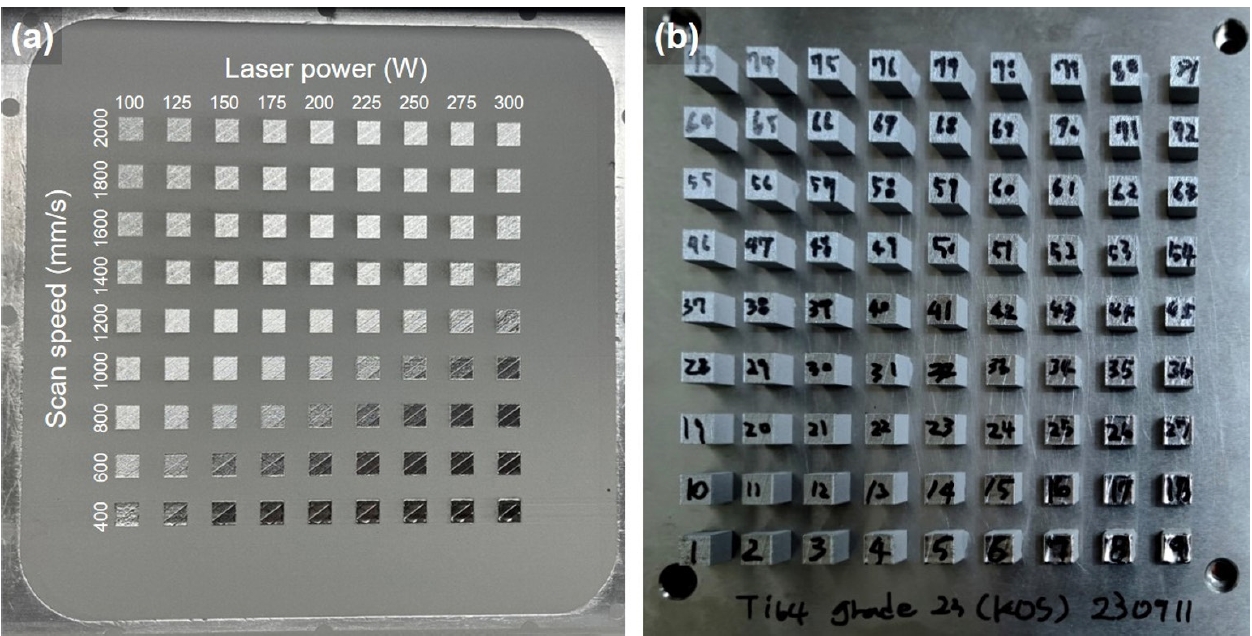

PDF - In order to predict the process window of laser powder bed fusion (LPBF) for printing metallic components, the calculation of volumetric energy density (VED) has been widely calculated for controlling process parameters. However, because it is assumed that the process parameters contribute equally to heat input, the VED still has limitation for predicting the process window of LPBF-processed materials. In this study, an explainable machine learning (xML) approach was adopted to predict and understand the contribution of each process parameter to defect evolution in Ti alloys in the LPBF process. Various ML models were trained, and the Shapley additive explanation method was adopted to quantify the importance of each process parameter. This study can offer effective guidelines for fine-tuning process parameters to fabricate high-quality products using LPBF.

-

Citations

Citations to this article as recorded by- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - From physics to intelligence: a review of AI-driven modeling strategies in laser direct energy deposition additive manufacturing

Seyedeh Fatemeh Nabavi, Saeid Nahavandi, Hamid Garmestani

Optics & Laser Technology.2026; 199: 114946. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Automated segmentation and analysis of microscopy images of laser powder bed fusion melt tracks

Aagam Shah, Reimar Weissbach, David A. Griggs, A. John Hart, Elif Ertekin, Sameh Tawfick

Journal of Manufacturing Processes.2025; 154: 61. CrossRef - Coefficient of Thermal Expansion of AlSi10Mg, 316L Stainless Steel and Ti6Al4V Alloys Made with Laser Powder Bed Fusion

Selami Emanet, Edem Honu, Kekeli Agbewornu, Evelyn Quansah, Congyuan Zeng, Patrick Mensah

Materials.2025; 18(19): 4468. CrossRef - Adaptive slicing for increased productivity of metal laser powder bed fusion

Lars Vanmunster, Louca R. Goossens, Laurent Sergeant, Brecht Van Hooreweder, Bey Vrancken

Additive Manufacturing.2025; 112: 105000. CrossRef

- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

- [English]

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 5,065 View

- 169 Download

- 5 Citations

-

Abstract

Abstract

PDF

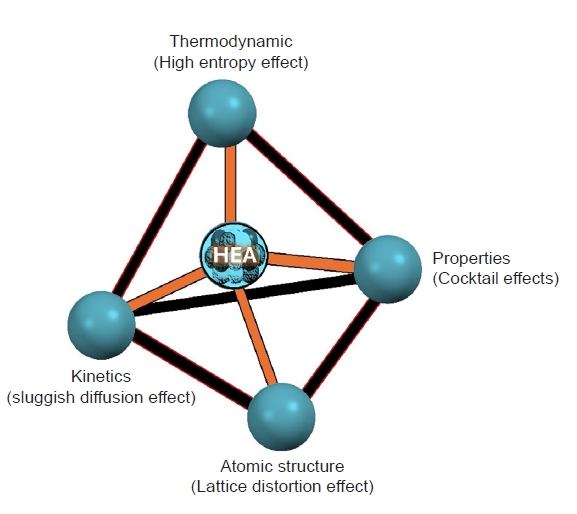

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

Leonardo Baylón García, José Manuel Mendoza Duarte, Ivanovich Estrada Guel, Audel Santos Beltrán, Hansel Manuel Medrano Prieto, Gustavo Rodríguez Cabriales, Enrique Rocha Rangel, José Luis Hernández Rivera, Roberto Martínez Sánchez, Alfredo Martínez Garcí

Coatings.2026; 16(3): 275. CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Latest Advancements and Mechanistic Insights into High-Entropy Alloys: Design, Properties and Applications

Anthoula Poulia, Alexander E. Karantzalis

Materials.2025; 18(24): 5616. CrossRef

- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

- [English]

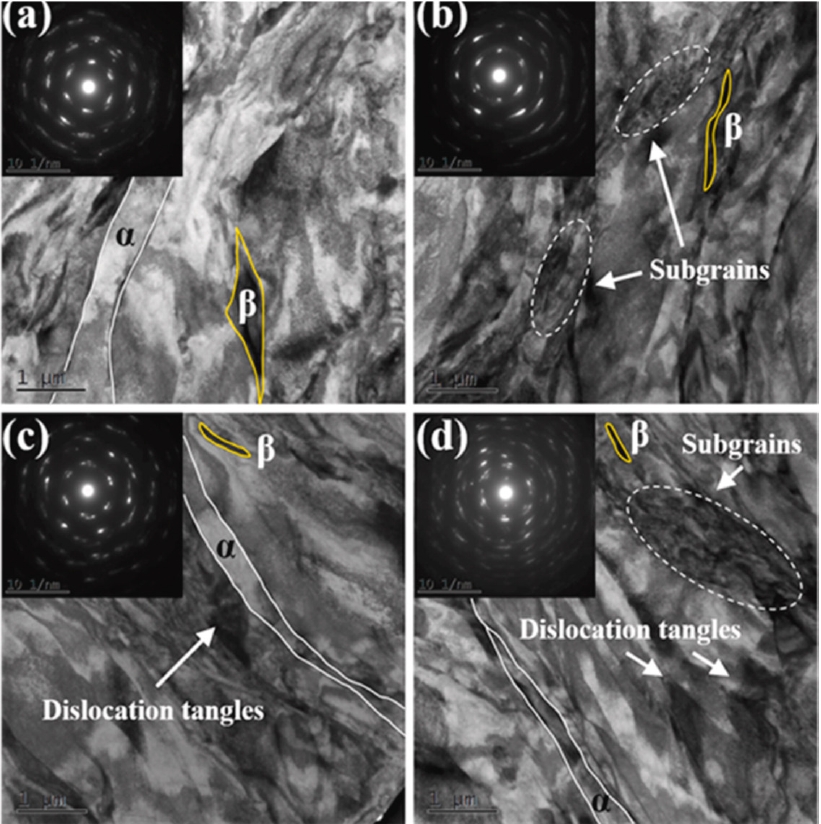

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

- Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

- J Powder Mater. 2024;31(1):8-15. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.8

- 4,538 View

- 139 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF The emergence of ferrous-medium entropy alloys (FeMEAs) with excellent tensile properties represents a potential direction for designing alloys based on metastable engineering. In this study, an FeMEA is successfully fabricated using laser powder bed fusion (LPBF), a metal additive manufacturing technology. Tensile tests are conducted on the LPBF-processed FeMEA at room temperature and cryogenic temperatures (77 K). At 77 K, the LPBF-processed FeMEA exhibits high yield strength and excellent ultimate tensile strength through active deformation-induced martensitic transformation. Furthermore, due to the low stability of the face-centered cubic (FCC) phase of the LPBF-processed FeMEA based on nano-scale solute heterogeneity, stress-induced martensitic transformation occurs, accompanied by the appearance of a yield point phenomenon during cryogenic tensile deformation. This study elucidates the origin of the yield point phenomenon and deformation behavior of the FeMEA at 77 K.

-

Citations

Citations to this article as recorded by- Stronger weld than base metal in face-centered cubic alloy through multi-scale heterogeneity

Yoona Lee, Sangwon Park, Dongwon Shin, Marcia Myung Hye Ahn, Wei Xiong, Nokeun Park, Hyoung Seop Kim, Je In Lee, Wookjin Lee, Yoon Suk Choi, Jeong Min Park, Namhyun Kang

Materials Research Letters.2026; : 1. CrossRef - Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

Journal of Powder Materials.2025; 32(2): 130. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Cryogenic tensile behavior of carbon-doped CoCrFeMnNi high-entropy alloys additively manufactured by laser powder bed fusion

Haeum Park, Hyeonseok Kwon, Kyung Tae Kim, Ji-Hun Yu, Jungho Choe, Hyokyung Sung, Hyoung Seop Kim, Jung Gi Kim, Jeong Min Park

Additive Manufacturing.2024; 86: 104223. CrossRef - Recent progress in high-entropy alloys for laser powder bed fusion: Design, processing, microstructure, and performance

Asker Jarlöv, Zhiguang Zhu, Weiming Ji, Shubo Gao, Zhiheng Hu, Priyanka Vivegananthan, Yujia Tian, Devesh Raju Kripalani, Haiyang Fan, Hang Li Seet, Changjun Han, Liming Tan, Feng Liu, Mui Ling Sharon Nai, Kun Zhou

Materials Science and Engineering: R: Reports.2024; 161: 100834. CrossRef

- Stronger weld than base metal in face-centered cubic alloy through multi-scale heterogeneity

- [English]

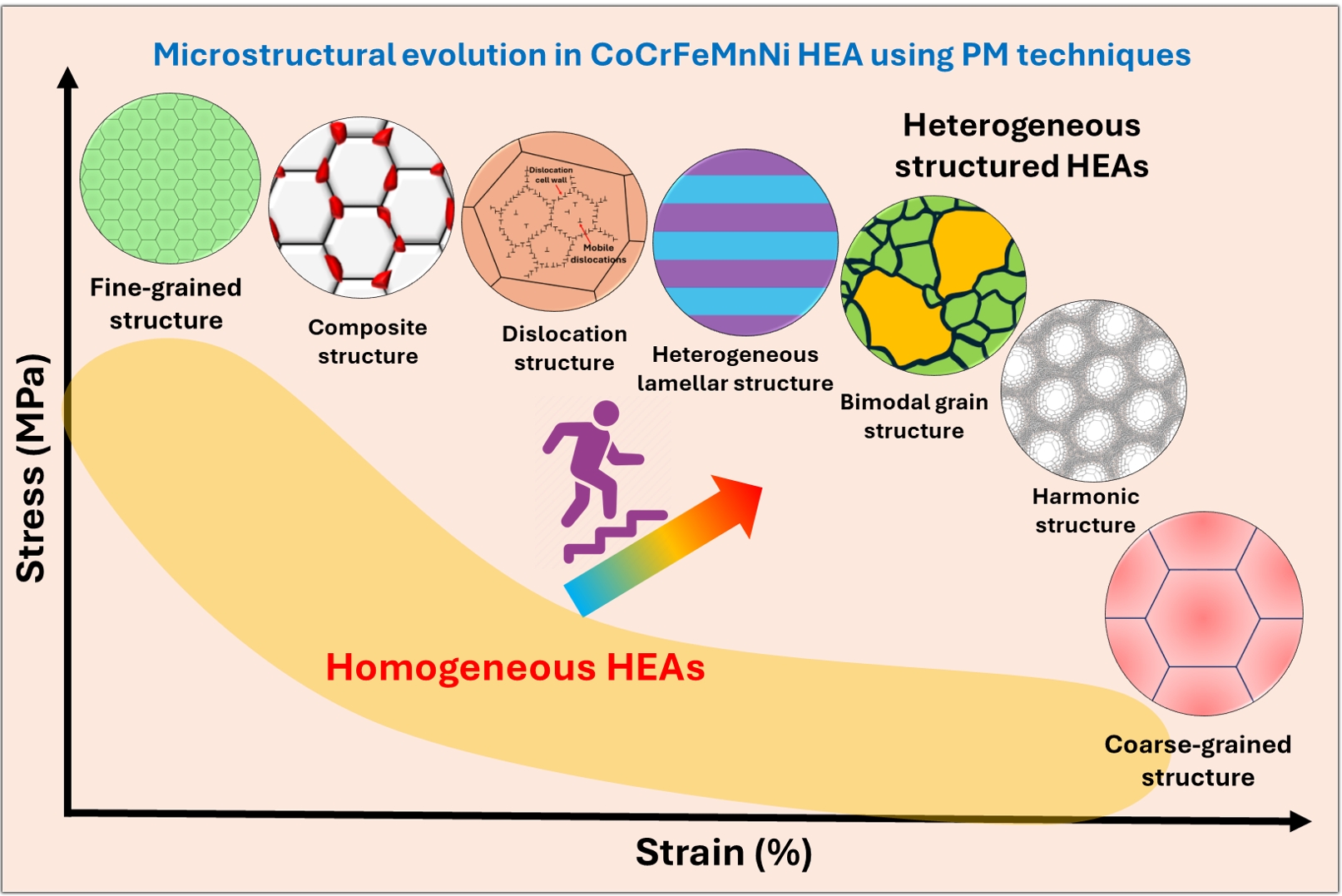

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,555 View

- 119 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

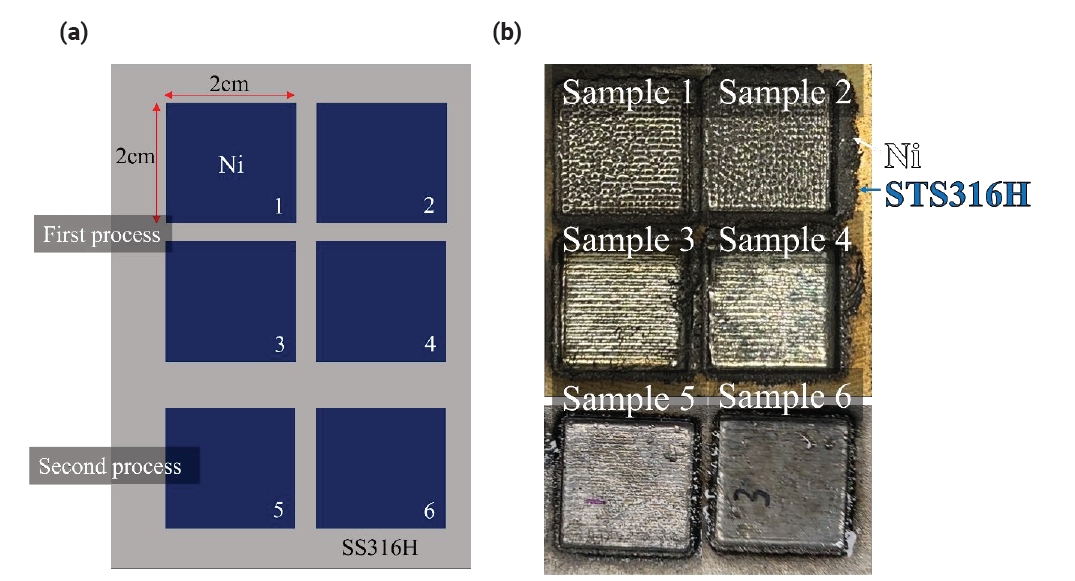

- Study on the Elemental Diffusion Distance of a Pure Nickel Layer Additively Manufactured on 316H Stainless Steel

- UiJun Ko, Won Chan Lee, Gi Seung Shin, Ji-Hyun Yoon, Jeoung Han Kim

- J Powder Mater. 2024;31(3):220-225. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00164

- 1,583 View

- 53 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF - Molten salt reactors represent a promising advancement in nuclear technology due to their potential for enhanced safety, higher efficiency, and reduced nuclear waste. However, the development of structural materials that can survive under severe corrosion environments is crucial. In the present work, pure Ni was deposited on the surface of 316H stainless steel using a directed energy deposition (DED) process. This study aimed to fabricate pure Ni alloy layers on an STS316H alloy substrate. It was observed that low laser power during the deposition of pure Ni on the STS316H substrate could induce stacking defects such as surface irregularities and internal voids, which were confirmed through photographic and SEM analyses. Additionally, the diffusion of Fe and Cr elements from the STS316H substrate into the Ni layers was observed to decrease with increasing Ni deposition height. Analysis of the composition of Cr and Fe components within the Ni deposition structures allows for the prediction of properties such as the corrosion resistance of Ni.

-

Citations

Citations to this article as recorded by- Microstructural analysis and characterization of nickel deposition on 316H stainless steel via gas tungsten arc welding and powder laser cladding

Won Chan Lee, Jin Woong Park, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 342. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef - Evaluation of Mechanical Properties of Pure Ni Coatings on a Type 316H Stainless Steel Substrate via High-Velocity Oxy-fuel and Directed Energy Deposition Processes

Won Chan Lee, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

Journal of Powder Materials.2025; 32(4): 309. CrossRef

- Microstructural analysis and characterization of nickel deposition on 316H stainless steel via gas tungsten arc welding and powder laser cladding

- [English]

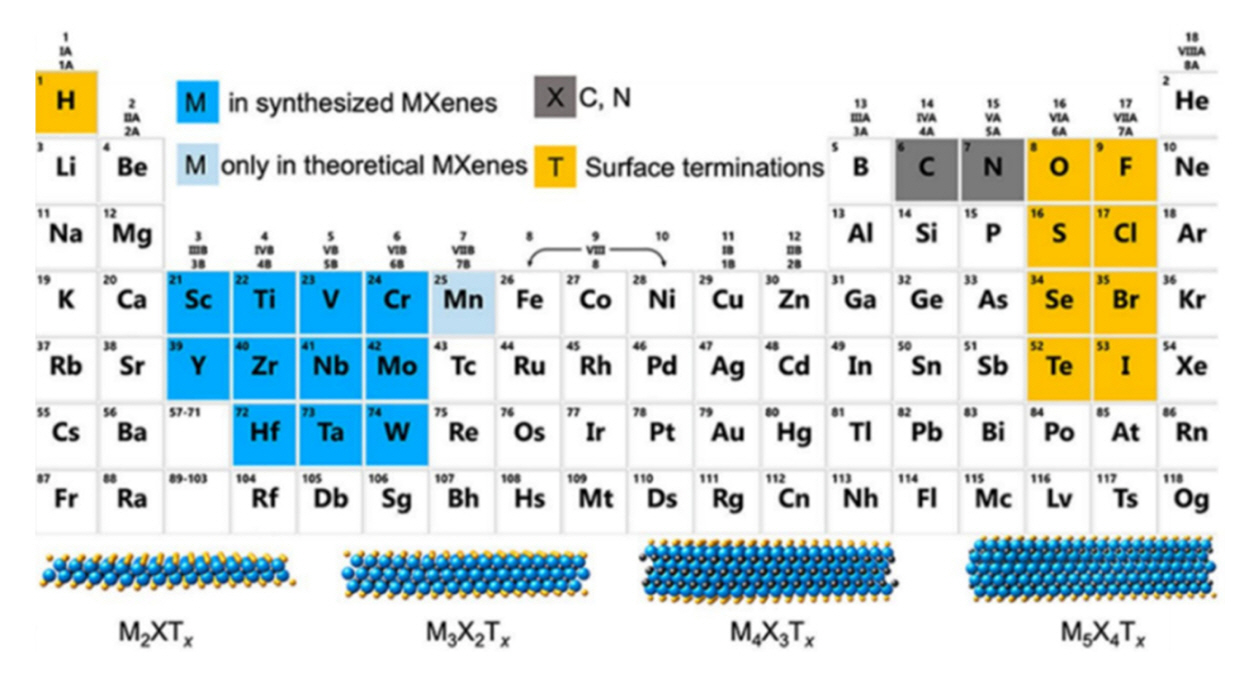

- Research Trends in Electromagnetic Shielding using MXene-based Composite Materials

- Siyeon Kim, Jongmin Byun

- J Powder Mater. 2024;31(1):57-76. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.57

- 8,339 View

- 163 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Recent advancements in electronic devices and wireless communication technologies, particularly the rise of 5G, have raised concerns about the escalating electromagnetic pollution and its potential adverse impacts on human health and electronics. As a result, the demand for effective electromagnetic interference (EMI) shielding materials has grown significantly. Traditional materials face limitations in providing optimal solutions owing to inadequacy and low performance due to small thickness. MXene-based composite materials have emerged as promising candidates in this context owing to their exceptional electrical properties, high conductivity, and superior EMI shielding efficiency across a broad frequency range. This review examines the recent developments and advantages of MXene-based composite materials in EMI shielding applications, emphasizing their potential to address the challenges posed by electromagnetic pollution and to foster advancements in modern electronics systems and vital technologies.

-

Citations

Citations to this article as recorded by- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

Pramod D. Mhase, Varsha C. Pujari, Santosh S. Jadhav, Abdullah G. Al-Sehemi, Sarah Alsobaie, Sunil M. Patange

Composites Communications.2025; 54: 102284. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Fabrication of MOF@MXene composites via surface modification of MXene under acidic conditions

Ji-Haeng Jeong, Woong-Ryeol Yu

Functional Composites and Structures.2025; 7(2): 025006. CrossRef - V2CTx MXene@ZIF-8 composite as an efficient adsorbent for Pb(II) removal from aqueous solution

Sarina Khojasteh Fard, Golshan Mazloom, Manoochehr Sobhani, Mohsen Tamtaji

Journal of Environmental Chemical Engineering.2025; 13(6): 120099. CrossRef

- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

- [English]

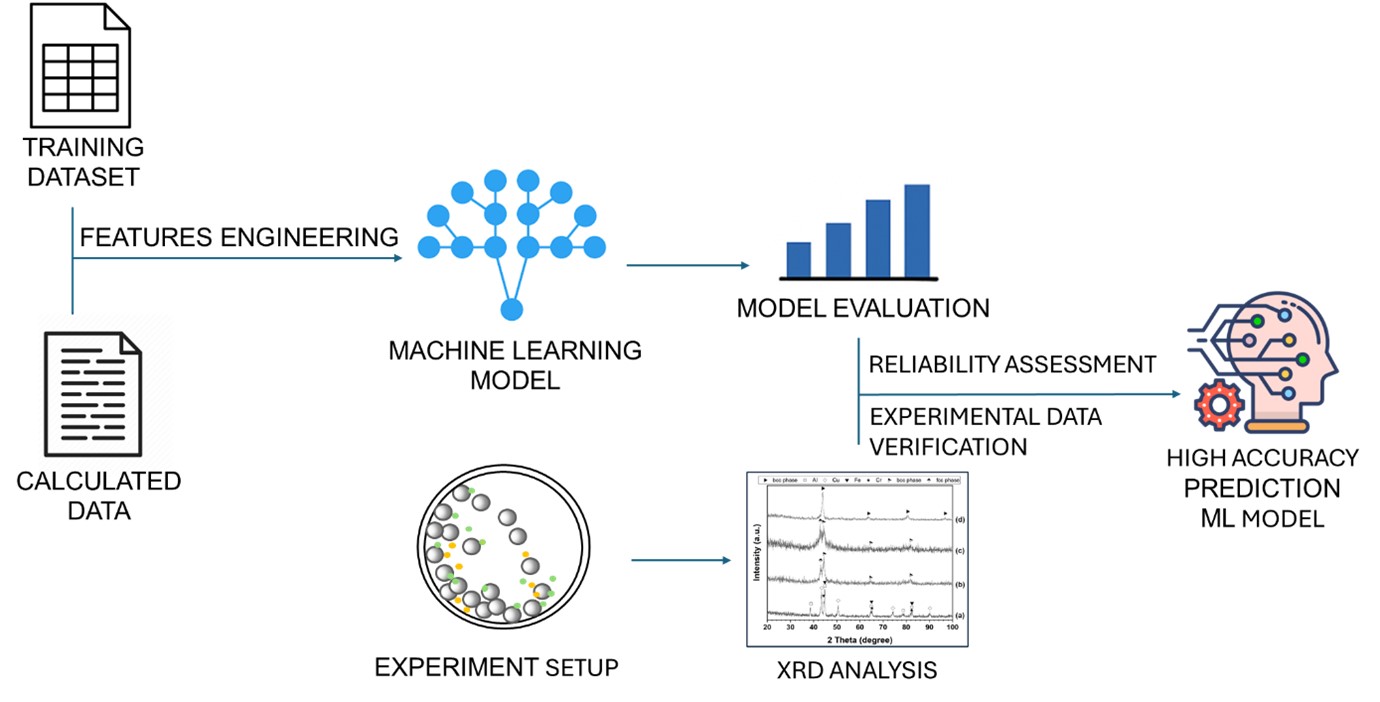

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- 2,462 View

- 81 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025; 56(5): 5948. CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; 8: 100038. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

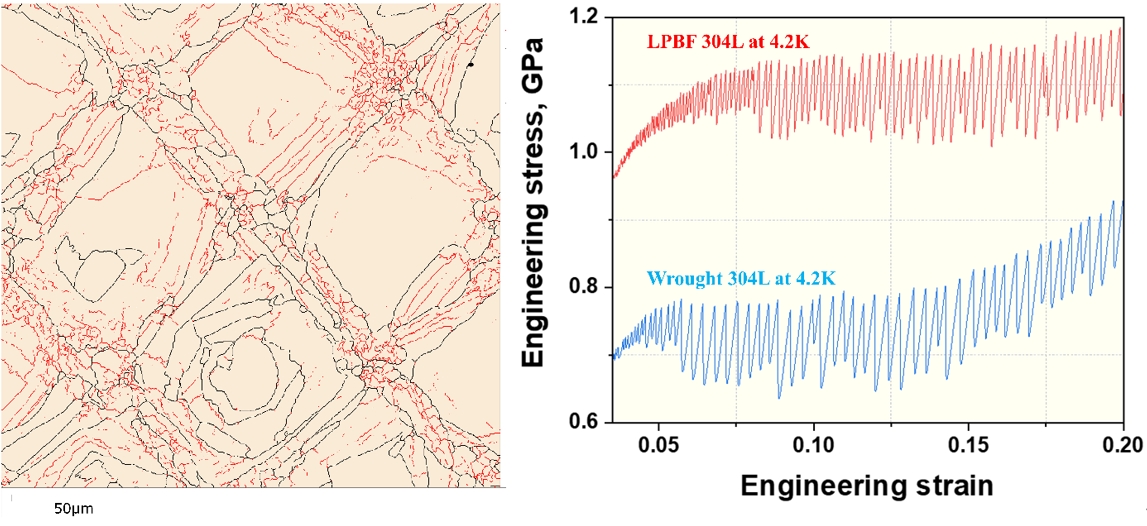

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 1,939 View

- 57 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

Haeum Park, Heechan Jung, Min Young Sung, Young-Kyun Kim, Jaimyun Jung, Yoona Lee, Namhyun Kang, Kyung Tae Kim, Young-Sang Na, Seok Su Sohn, Jeong Min Park

Materials Science and Engineering: A.2026; 950: 149460. CrossRef - Twinning- and transformation-induced high cryogenic strength and ductility of the CoCrFeNi high-entropy alloy: Experiment and MD simulation

Yuze Wu, Zhide Li, Charlie Kong, M.W. Fu, Hailiang Yu

International Journal of Plasticity.2026; 196: 104553. CrossRef - Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

- [English]

- Epsilon Iron Oxide (ε-Fe2O3) as an Electromagnetic Functional Material: Properties, Synthesis, and Applications

- Ji Hyeong Jeong, Hwan Hee Kim, Jung-Goo Lee, Youn-Kyoung Baek

- J Powder Mater. 2024;31(6):465-479. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00290

- 3,539 View

- 92 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - Iron oxide (ε-Fe₂O₃) is emerging as a promising electromagnetic material due to its unique magnetic and electronic properties. This review focuses on the intrinsic properties of ε-Fe₂O₃, particularly its high coercivity, comparable to that of rare-earth magnets, which is attributed to its significant magnetic anisotropy. These properties render it highly suitable for applications in millimeter wave absorption and high-density magnetic storage media. Furthermore, its semiconducting behavior offers potential applications in photocatalytic hydrogen production. The review also explores various synthesis methods for fabricating ε-Fe₂O₃ as nanoparticles or thin films, emphasizing the optimization of purity and stability. By exploring and harnessing the properties of ε-Fe₂O₃, this study aims to contribute to the advancement of next-generation electromagnetic materials with potential applications in 6G wireless telecommunications, spintronics, high-density data storage, and energy technologies.

-

Citations

Citations to this article as recorded by- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

Babak Enami Alamdari, Yu Tang, Danilo Erricolo, Lesley H. Sneed

Journal of Nondestructive Evaluation.2026;[Epub] CrossRef - Chemical Pressure Induced Strain Control of Magnetic Anisotropy in the Simple Perovskite ϵ-Fe2O3

Subir Roy, Gurleen K. Uppal, Alberto Acosta, Rachel Nickel, Charles A. Roberts, Johan van Lierop

Nano Letters.2026; 26(1): 34. CrossRef - Superparamagnetism of Baked Clays Containing Polymorphs of Iron Oxides: Experimental Study and Theoretical Modeling

Petr Kharitonskii, Andrei Krasilin, Nadezhda Belskaya, Svetlana Yanson, Nikita Bobrov, Andrey Ralin, Kamil Gareev, Nikita Zolotov, Dmitry Zaytsev, Elena Sergienko

Magnetochemistry.2025; 11(12): 103. CrossRef

- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

- [English]

- A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

- Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

- J Powder Mater. 2024;31(5):390-398. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00325

- 2,206 View

- 65 Download

- 3 Citations

-

Abstract

Abstract

PDF

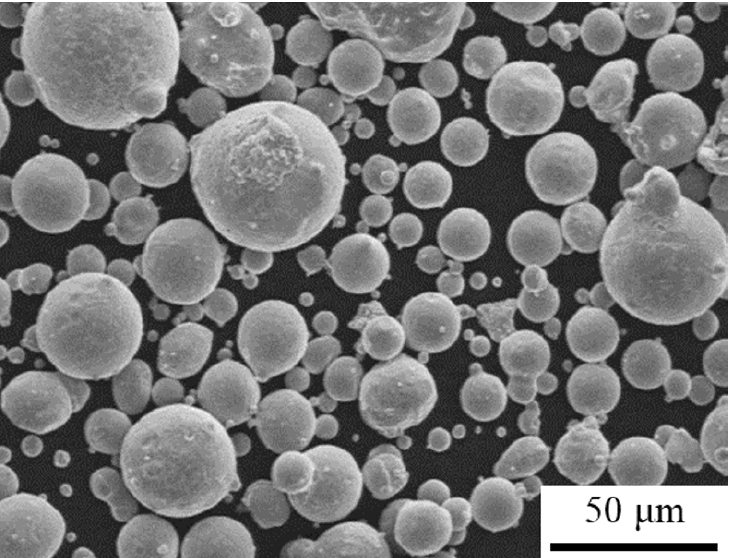

PDF - The AlSi10Mg alloy has garnered significant attention for its application in laser powder bed fusion (L-PBF), due to its lightweight properties and good printability using L-PBF. However, the low production speed of the L-PBF process is the main bottleneck in the industrial commercialization of L-PBF AlSi10Mg alloy parts. Furthermore, while L-PBF AlSi10Mg alloy exhibits excellent mechanical properties, the properties are often over-specified compared to the target properties of parts traditionally fabricated by casting. To accelerate production speed in L-PBF, this study investigated the effects of process parameters on the build rate and mechanical properties of the AlSi10Mg alloy. Guidelines are proposed for high-speed additive manufacturing of the AlSi10Mg alloy for use in automotive parts. The results show a significant increase in the build rate, exceeding the conventional build rate by a factor of 3.6 times or more, while the L-PBF AlSi10Mg alloy met the specifications for automotive prototype parts. This strategy can be expected to offer significant cost advantages while maintaining acceptable mechanical properties of topology-optimized parts used in the automobile industry.

-

Citations

Citations to this article as recorded by- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - Lightweight Design of a Connecting Rod Using Lattice-Structure Parameter Optimisation: A Test Case for L-PBF

Michele Amicarelli, Michele Trovato, Paolo Cicconi

Machines.2025; 13(3): 171. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

- [English]

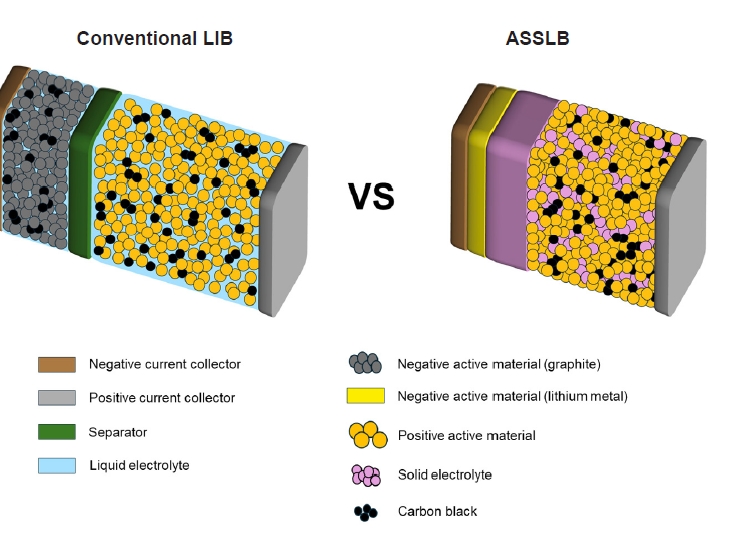

- A Review of Inorganic Solid Electrolytes for All-Solid-State Lithium Batteries: Challenges and Progress

- Seul Ki Choi, Jaehun Han, Gi Jeong Kim, Yeon Hee Kim, Jaewon Choi, MinHo Yang

- J Powder Mater. 2024;31(4):293-301. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00206

- 11,812 View

- 288 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - All-solid-state lithium batteries (ASSLBs) are receiving attention as a prospective next-generation secondary battery technology that can reduce the risk of commercial lithium-ion batteries by replacing flammable organic liquid electrolytes with non-flammable solid electrolytes. The practical application of ASSLBs requires developing robust solid electrolytes that possess ionic conductivity at room temperature on a par with that of organic liquids. These solid electrolytes must also be thermally and chemically stable, as well as compatible with electrode materials. Inorganic solid electrolytes, including oxide and sulfide-based compounds, are being studied as promising future candidates for ASSLBs due to their higher ionic conductivity and thermal stability than polymer electrolytes. Here, we present the challenges currently facing the development of oxide and sulfide-based solid electrolytes, as well as the research efforts underway aiming to resolve these challenges.

-

Citations

Citations to this article as recorded by- A facile synthesis of bulk LiPON in solution for solid-state electrolytes

Osma J. Gomez, Adam Antar, Alex T. Hall, Leopoldo Tapia-Aracayo, Joshua Seo, Nam Kim, Zihan Sun, Ryan Lim, Fu Chen, Yue Li, John Cumings, Gary Rubloff, Sang Bok Lee, David Stewart, Yang Wang

Journal of Materials Chemistry A.2025; 13(34): 28368. CrossRef - Uniform lithium deposition using Cu teepee structures for anode-free lithium metal batteries

Seo Yun Jung, Jaehun Han, Seul Ki Choi, Se Youn Cho, Jong Ho Won, Jaewon Choi, Minho Yang

Chemical Engineering Journal.2025; 522: 167302. CrossRef - Garnet-type LLZO electrolytes for solid-state lithium batteries: Interfaces, conductivity, in-situ processing, and industrial prospects

Kaleab Habtamu Ayalew, Nithyadharseni Palaniyandy, Mkhulu K. Mathe, Phumlani F. Msomi

Chemical Engineering Journal.2025; 524: 168098. CrossRef

- A facile synthesis of bulk LiPON in solution for solid-state electrolytes

- [English]

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

- J Powder Mater. 2024;31(5):365-373. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00213

- 2,855 View

- 67 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - This review examines the microstructural and mechanical properties of a Ti-6Al-4V alloy produced by wrought processing and powder metallurgy (PM), specifically laser powder bed fusion (LPBF) and hot isostatic pressing. Wrought methods, such as forging and rolling, create equiaxed alpha (α) and beta (β) grain structures with balanced properties, which are ideal for fatigue resistance. In contrast, PM methods, particularly LPBF, often yield a martensitic α′ structure with high microhardness, enabling complex geometries but requiring post-processing to improve its properties and reduce stress. The study evaluated the effects of processing parameters on grain size, phase distribution, and material characteristics, guiding the choice of fabrication techniques for optimizing Ti-6Al-4V performance in aerospace, biomedical, and automotive applications. The analysis emphasizes tailored processing to meet advanced engineering demands.

-

Citations

Citations to this article as recorded by- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

- Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00185

- 1,299 View

- 40 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

- Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

- J Powder Mater. 2024;31(4):302-307. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00157

- 1,573 View

- 35 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - This study explored the process-structure-property (PSP) relationships in Ti-6Al-4V alloys fabricated through direct energy deposition (DED) additive manufacturing. A systematic investigation was conducted to clarify how process variables—specifically, manipulating the cooling rate and energy input by adjusting the laser power and scan speed during the DED process—influenced the phase fractions, pore structures, and the resultant mechanical properties of the samples under various processing conditions. Significant links were found between the controlled process parameters and the structural and mechanical characteristics of the produced alloys. The findings of this research provide foundational knowledge that will drive the development of more effective and precise control strategies in additive manufacturing, thereby improving the performance and reliability of produced materials. This, in turn, promises to make significant contributions to both the advancement of additive manufacturing technologies and their applications in critical sectors.

-

Citations

Citations to this article as recorded by- Microstructural and tribological performance of Ti6Al4V alloy modified by laser surface texturing

Bryan Ivan Quintanar-Abarca, Dulce Viridiana Melo-Máximo, Lizbeth Melo-Máximo, Esmeralda Uribe-Lam, Erika García-López

Journal of Materials Science.2026; 61(2): 1309. CrossRef - Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef

- Microstructural and tribological performance of Ti6Al4V alloy modified by laser surface texturing

- [Korean]

- Effect of Anisotropy on the Wear Behavior of Age-Treated Maraging Steel Manufactured by LPBF

- Seung On Lim, Se-Eun Shin

- J Powder Mater. 2024;31(4):308-317. Published online August 5, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00171

- 2,137 View

- 38 Download

- 2 Citations

-

Abstract

Abstract

PDF

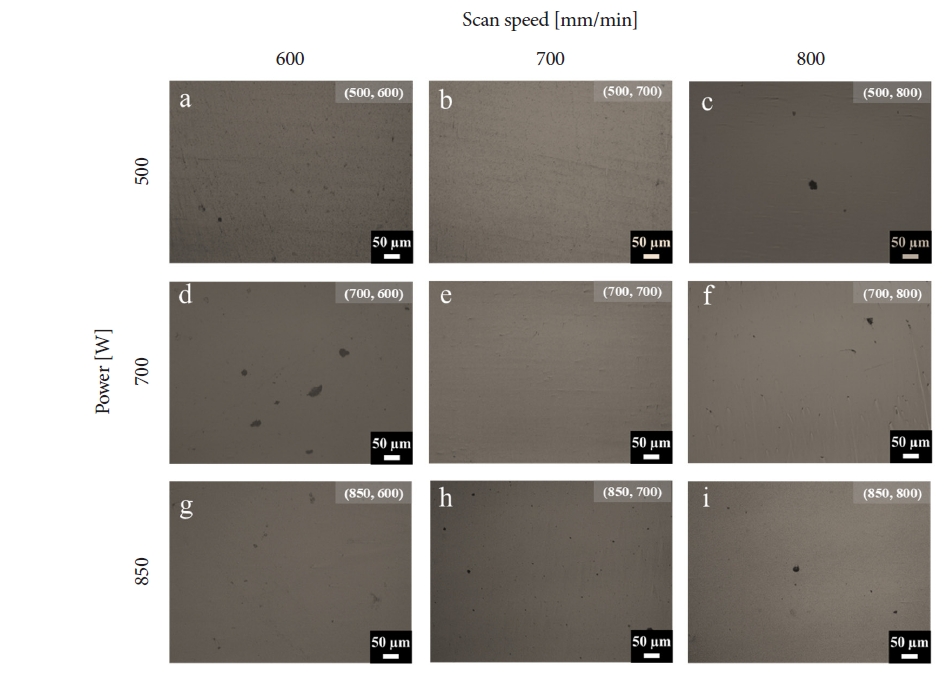

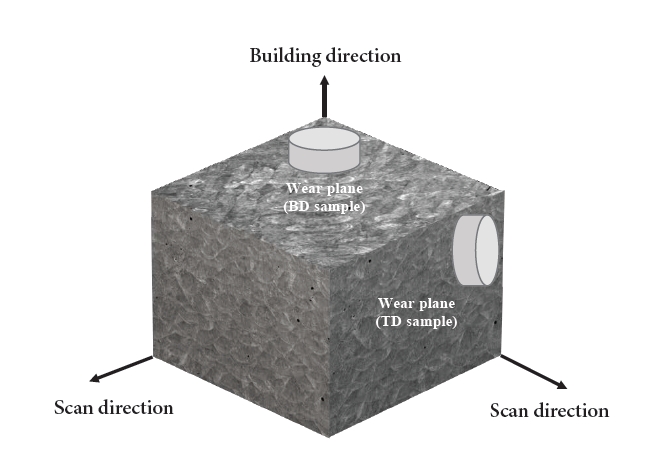

PDF - Maraging steel has excellent mechanical properties resulting from the formation of precipitates within the matrix through aging treatment. Maraging steel fabricated by the laser powder bed fusion (LPBF) process is suitable for applications including precise components and optimized design. The anisotropic characteristic, which depends on the stacking direction, affects the mechanical properties. This study aimed to analyze the influence of anisotropy on the wear behavior of maraging steel after aging treatment. The features of additive manufacturing tended to disappear after heat treatment. However, some residual cellular and dendrite structures were observed. In the wear tests, a high wear rate was observed on the building direction plane for all counter materials. This is believed to be because the oxides formed on the wear track positively affected the wear characteristics; meanwhile, the bead shape in the stacking direction surface was vulnerable to wear, leading to significant wear.

-

Citations

Citations to this article as recorded by- Unveiling age-hardening mechanisms: first-principles carbide insights and enhanced thermomechanical fatigue in niobium-bearing austenitic stainless steels

Godwin Kwame Ahiale, Jin Woong Park, Raj Narayan Hajra, Yong-Jun Oh, Won Doo Choi, Tae-Wook Na, Gi Yong Kim, Hyun-Ju Choi, Jeoung Han Kim

Materials Science and Engineering: A.2026; 949: 149397. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Unveiling age-hardening mechanisms: first-principles carbide insights and enhanced thermomechanical fatigue in niobium-bearing austenitic stainless steels

- [English]

- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

- Seoyeon Jeon, Hyunjoo Choi

- J Powder Mater. 2024;31(3):213-219. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00150

- 2,699 View

- 74 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - Additive Manufacturing (AM) is a process that fabricates products by manufacturing materials according to a three-dimensional model. It has recently gained attention due to its environmental advantages, including reduced energy consumption and high material utilization rates. However, controlling defects such as melting issues and residual stress, which can occur during metal additive manufacturing, poses a challenge. The trial-and-error verification of these defects is both time-consuming and costly. Consequently, efforts have been made to develop phenomenological models that understand the influence of process variables on defects, and mechanical/electrical/thermal properties of geometrically complex products. This paper introduces modeling techniques that can simulate the powder additive manufacturing process. The focus is on representative metal additive manufacturing processes such as Powder Bed Fusion (PBF), Direct Energy Deposition (DED), and Binder Jetting (BJ) method. To calculate thermal-stress history and the resulting deformations, modeling techniques based on Finite Element Method (FEM) are generally utilized. For simulating the movements and packing behavior of powders during powder classification, modeling techniques based on Discrete Element Method (DEM) are employed. Additionally, to simulate sintering and microstructural changes, techniques such as Monte Carlo (MC), Molecular Dynamics (MD), and Phase Field Modeling (PFM) are predominantly used.

-

Citations

Citations to this article as recorded by- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

- [English]

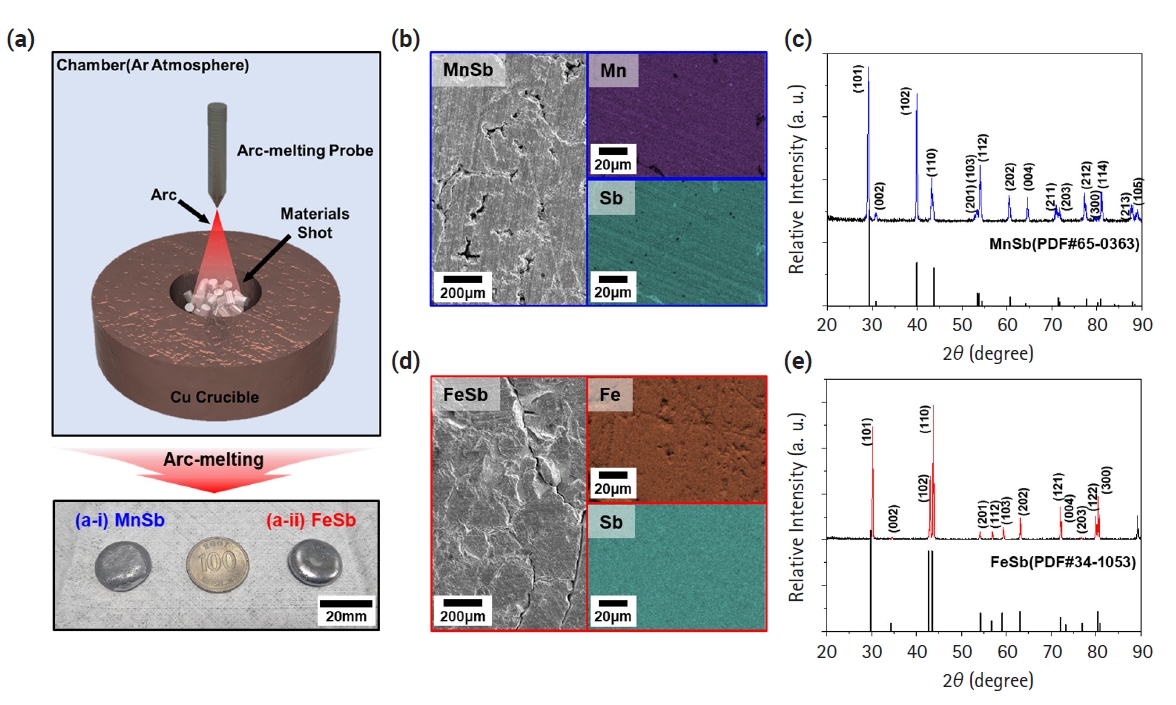

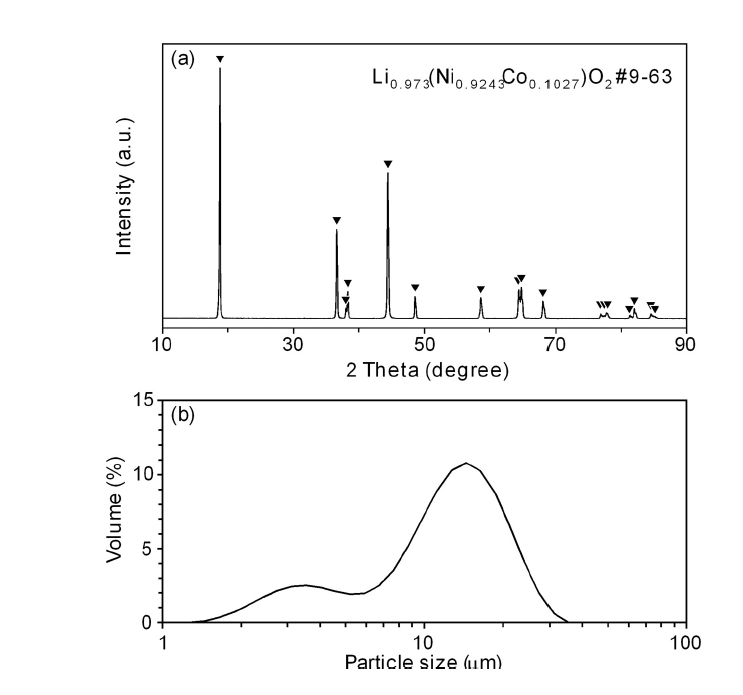

- Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

- Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

- J Powder Mater. 2024;31(3):236-242. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00031

- 1,826 View

- 44 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - The development of thermoelectric (TE) materials to replace Bi2Te3 alloys is emerging as a hot issue with the potential for wider practical applications. In particular, layered Zintl-phase materials, which can appropriately control carrier and phonon transport behaviors, are being considered as promising candidates. However, limited data have been reported on the thermoelectric properties of metal-Sb materials that can be transformed into layered materials through the insertion of cations. In this study, we synthesized FeSb and MnSb, which are used as base materials for advanced thermoelectric materials. They were confirmed as single-phase materials by analyzing X-ray diffraction patterns. Based on electrical conductivity, the Seebeck coefficient, and thermal conductivity of both materials characterized as a function of temperature, the zT values of MnSb and FeSb were calculated to be 0.00119 and 0.00026, respectively. These properties provide a fundamental data for developing layered Zintl-phase materials with alkali/alkaline earth metal insertions.

-

Citations

Citations to this article as recorded by- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

Jong Min Park, Seungki Jo, Soo-ho Jung, Jinhee Bae, Linh Ba Vu, Jihun Yu, Kyung Tae Kim

Materials Letters.2025; 381: 137796. CrossRef - Highly deformable and hierarchical 3D composite sponge for versatile thermoelectric energy conversion

Jong Min Park, Changyeon Baek, Min-Ku Lee, Nagamalleswara Rao Alluri, Gyoung-Ja Lee, Kyung Tae Kim, Kwi-Il Park

Applied Surface Science.2025; 692: 162730. CrossRef

- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

- [Korean]

- Effect of Abnormal Grain Growth on Ionic Conductivity in LATP

- Hyungik Choi, Yoonsoo Han

- J Powder Mater. 2024;31(1):23-29. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.23

- 2,986 View

- 66 Download

- 2 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Temperature-dependent microstructural evolution in a compositionally complex solid electrolyte: The role of a grain boundary transition

Shu-Ting Ko, Chaojie Du, Huiming Guo, Hasti Vahidi, Jenna L. Wardini, Tom Lee, Yi Liu, Jingjing Yang, Francisco Guzman, Timothy J. Rupert, William J. Bowman, Shen J. Dillon, Xiaoqing Pan, Jian Luo

Journal of Advanced Ceramics.2025; 14(3): 9221047. CrossRef - Effect of bimodal particle size distribution on Li1.5Al0.5Ti1.5(PO4)3 solid electrolytes: Microstructures and electrochemical properties

Gi Jeong Kim, Yeon Hee Kim, Seul Ki Choi, Jong Won Bae, Kun-Jae Lee, Minho Yang

Powder Technology.2025; 466: 121407. CrossRef

- Temperature-dependent microstructural evolution in a compositionally complex solid electrolyte: The role of a grain boundary transition

- [English]

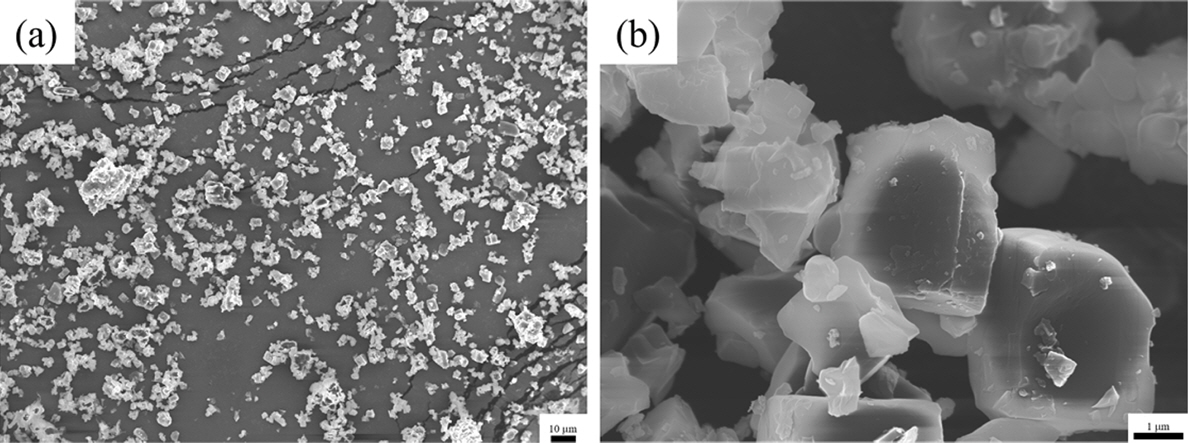

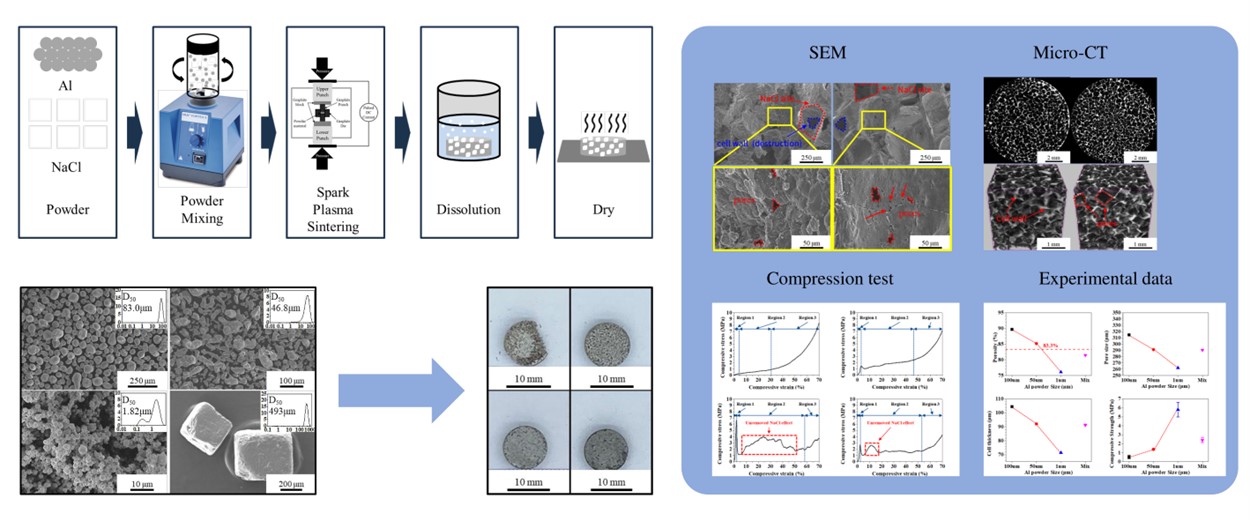

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,392 View

- 55 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [English]

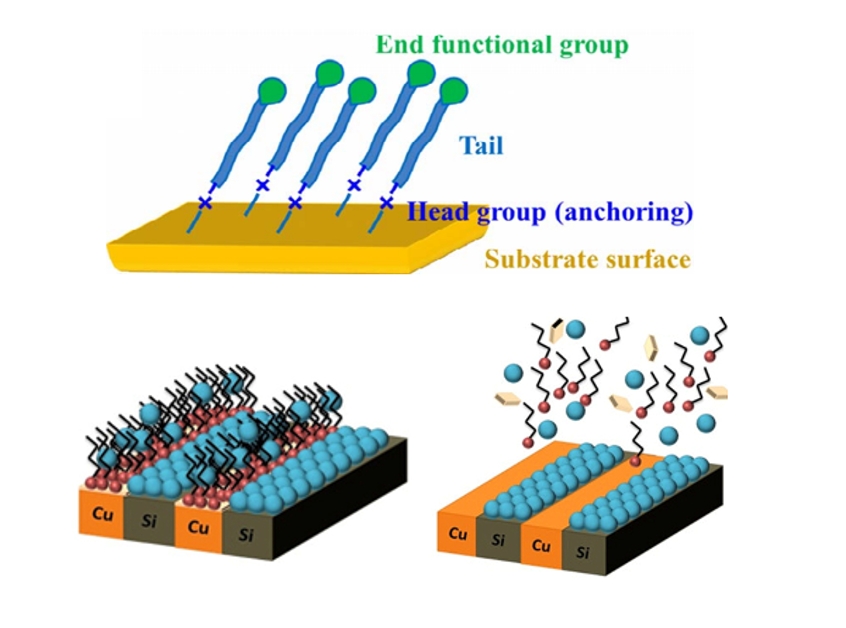

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- 4,828 View

- 181 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

-

Citations

Citations to this article as recorded by- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

Hojeong Yoon, Saima Sadiq, Junhyeok Park, Kyungwon Kwak, Minhaeng Cho

The Journal of Physical Chemistry Letters.2026; 17(4): 1119. CrossRef

- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

- [Korean]

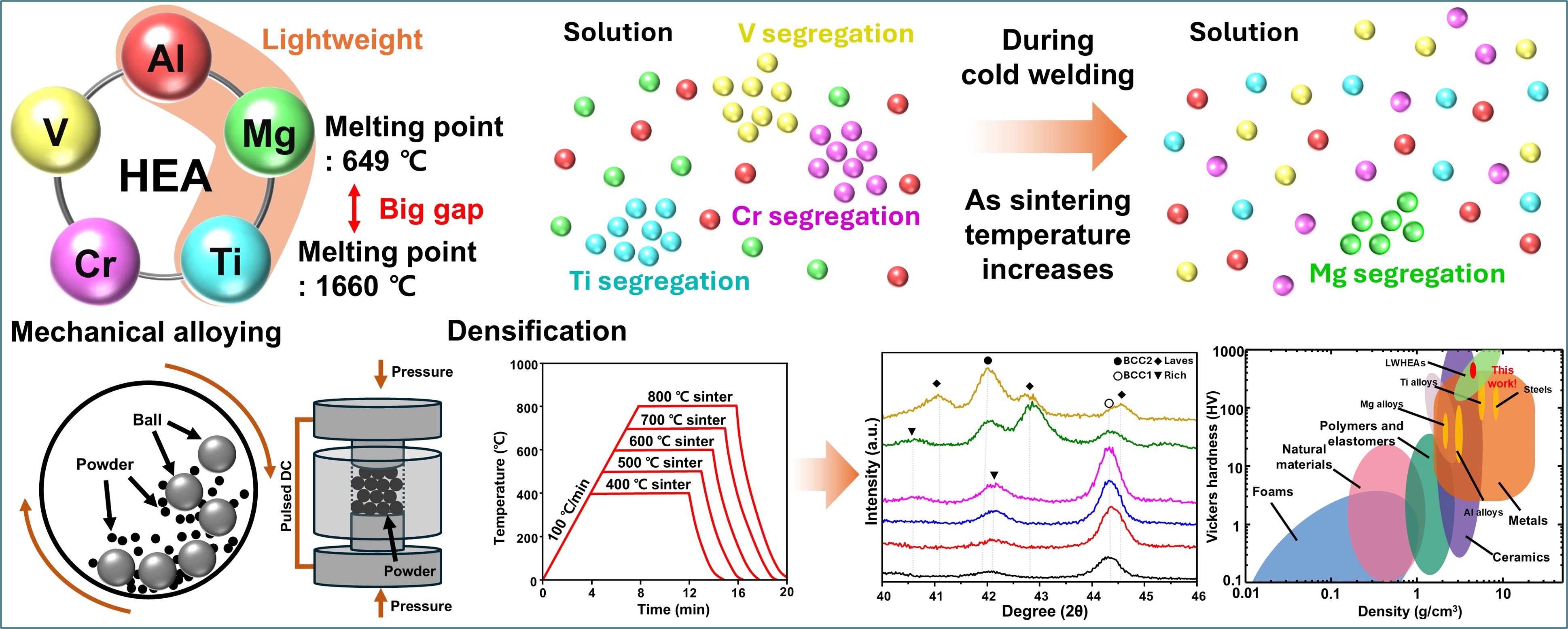

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- 669 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

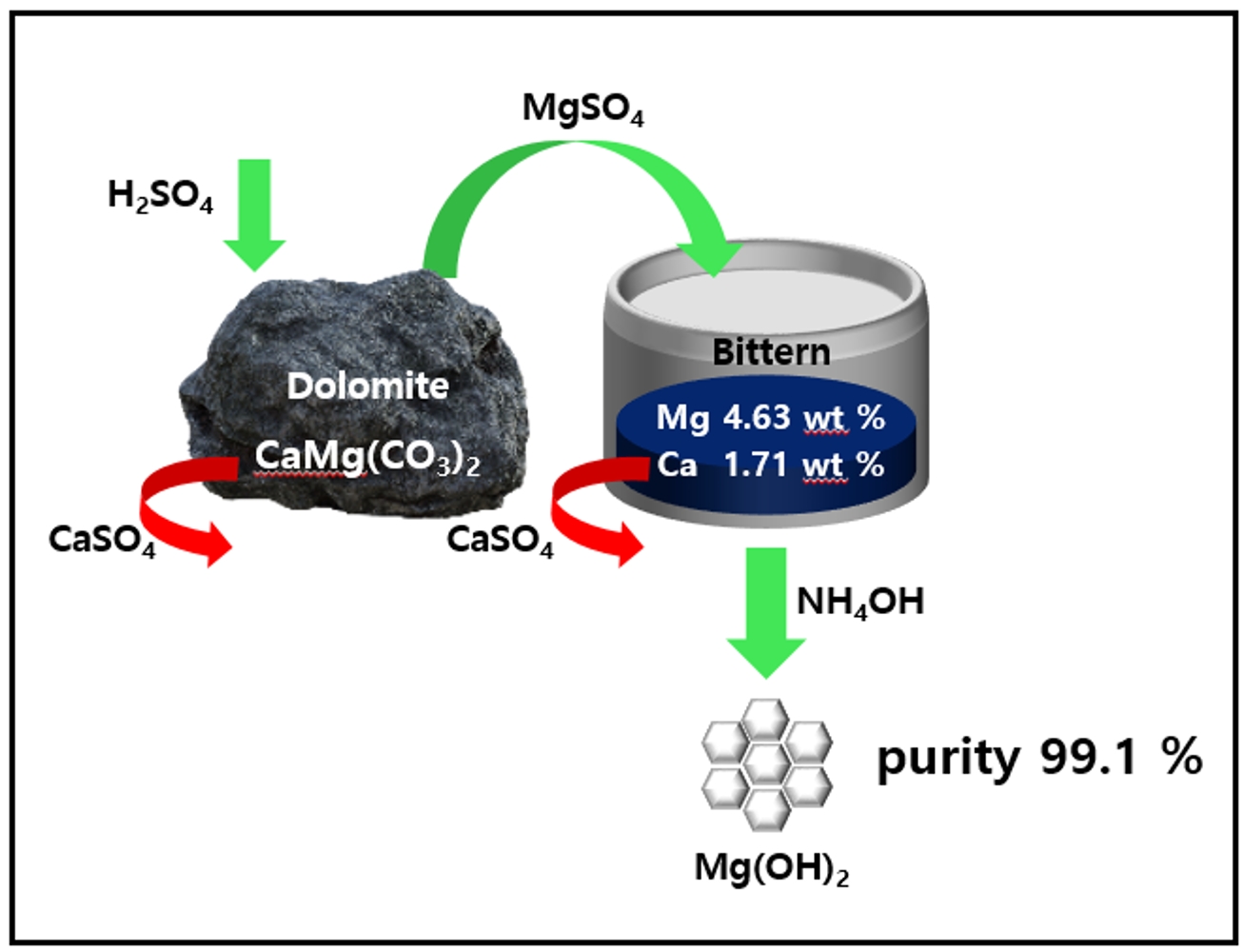

- Extraction of MgSO4 from dolomite and synthesis of Mg(OH)2 in Bittern

- HyunSeung Shim, Jiyeon Kim, Areum Choi, Nuri Oh, YooJin Kim

- J Powder Mater. 2025;32(2):122-130. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00073

- 949 View

- 33 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - We synthesized magnesium hydroxide using bittern and dolomite, which are domestic resources. In Bittern, there is a high concentration of Mg2+ ions, but the impurity Ca2+ ion content is also significant, requiring a purification process to remove it. There are two main methods for this purification. Firstly, there is a separation method that utilizes the difference in solubility between Mg2+ ions and Ca2+ ions by using sulfuric acid on dolomite. Adding MgSO4 solution from dolomite to Bittern removes Ca2+ ions as CaSO4. This process simultaneously purifies Ca impurities and increases the Mg/Ca ratio by adding extra Mg2+ ions. In this study, purified bittern was obtained by using dolomite and sulfuric acid to extract MgSO4, which was then used to purify Ca2+ ions. High-purity Mg(OH)2 was synthesized by optimizing the NaOH and NH4OH ratio as an alkaline precipitant.

-

Citations

Citations to this article as recorded by- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

Journal of Powder Materials.2025; 32(5): 399. CrossRef

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- [Korean]

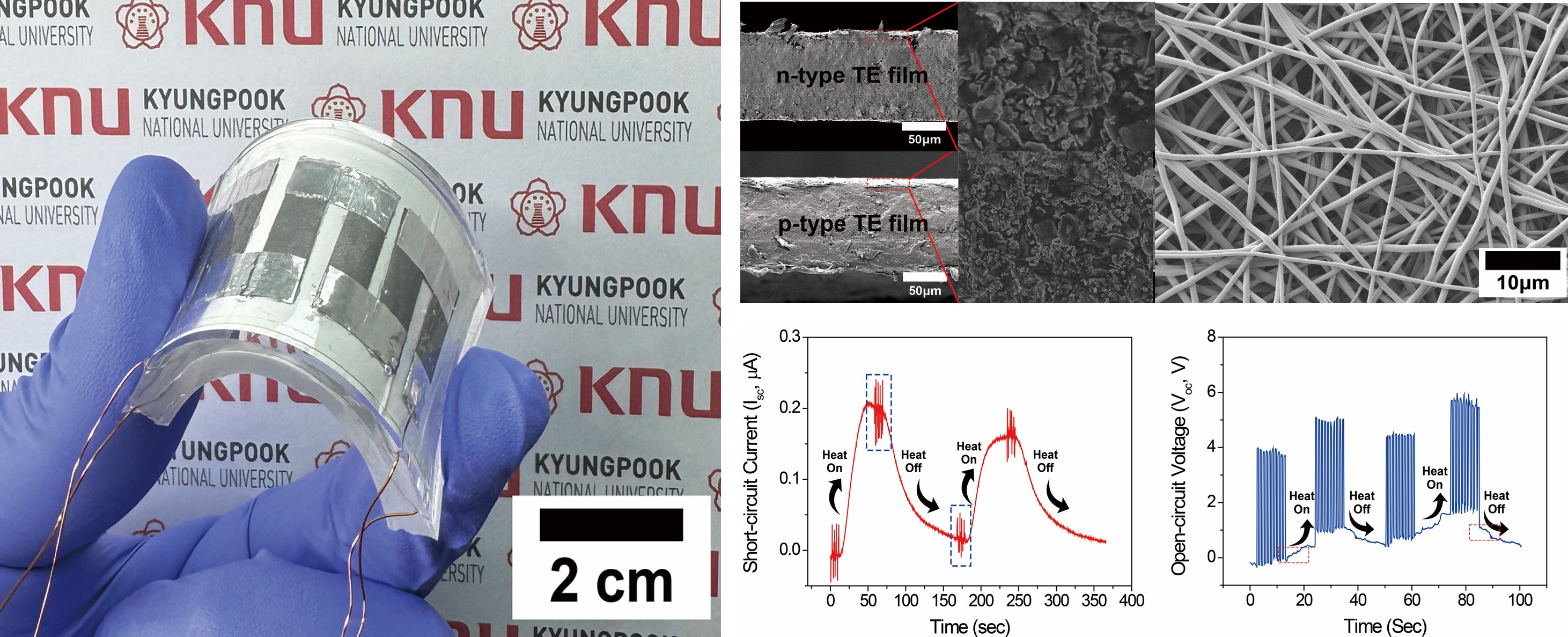

- Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

- Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

- J Powder Mater. 2025;32(2):104-112. Published online March 4, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00458

- 978 View

- 33 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - A hybrid energy harvester that consisted of thermoelectric (TE) composite film and electrospun piezoelectric (PE) polymeric membranes was constructed. TE composites were fabricated by dispersing inorganic TE powders inside polyvinylidene fluoride elastomer using a drop-casting technique. The polyvinylidene fluoride-trifluoroethylene, which was chosen due to its excellent chemical resistance, mechanical stability, and biocompatibility, was electrospun onto an aluminum foil to fabricate the ultra-flexible PE membranes. To create a hybrid energy harvester that can simultaneously convert heat and mechanical energy resources into electricity, the TE composite films attached to the PE membrane were encapsulated with protective polydimethylsiloxane. The fabricated energy harvester converted the outputs with a maximum voltage of 4 V (PE performance) and current signals of 0.2 μA (TE performance) under periodical heat input and mechanical bending in hybrid modes. This study demonstrates the potential of the hybrid energy harvester for powering flexible and wearable electronics, offering a sustainable and reliable power source.

-

Citations

Citations to this article as recorded by- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

HyoMin Jeon, Seo Young Yoon, Nagamalleswara Rao Alluri, Momanyi Amos Okirigiti, HakSu Jang, Changyeon Baek, Tiandong Zhang, Geon-Tae Hwang, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Sustainable Materials and Technologies.2026; 47: e01888. CrossRef

- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

- [Korean]

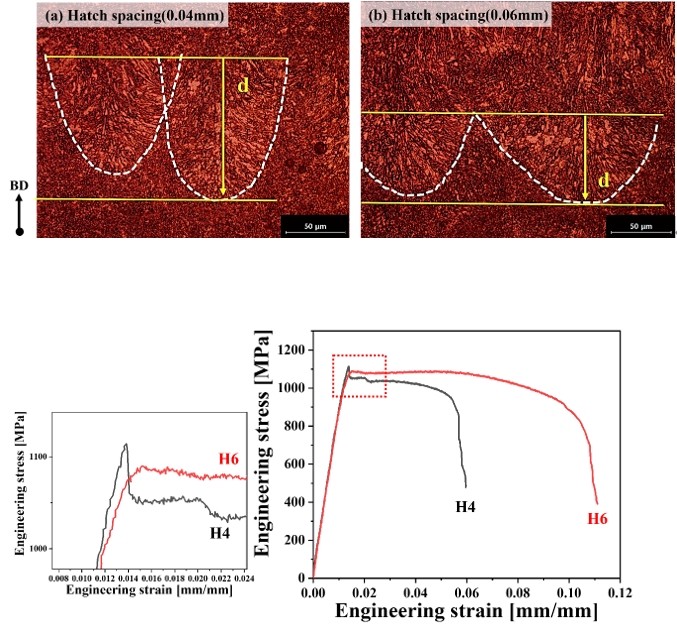

- Effect of Hatch Spacing on the Microstructure and Mechanical Properties of SA508 Gr.3 Steel Fabricated by Laser Powder Bed Fusion

- Yuanjiu Huang, Ho Jin Ryu, Kee-Ahn Lee

- J Powder Mater. 2025;32(1):50-58. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00479

- 1,177 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the effect of the hatch spacing parameter on the microstructure and mechanical properties of SA508 Gr.3 steel manufactured by laser powder bed fusion (L-PBF) for a nuclear pressure vessel. Materials were prepared with varying hatch spacing (0.04 mm [H4] and 0.06 mm [H6]). The H4 exhibited finer and more uniformly distributed grains, while the H6 showed less porosity and a lower defect fraction. The yield strength of the H4 material was higher than that of the H6 material, but there was a smaller difference between the materials in tensile strength. The measured elongation was 5.65% for the H4 material and 10.41% for the H6 material, showing a significantly higher value for H6. An explanation for this is that although the H4 material had a microstructure of small and uniform grains, it contained larger and more numerous pore defects than the H6 material, facilitating stress concentration and the initiation of microcracks.

-

Citations

Citations to this article as recorded by- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

Kwangtae Son, Seung-Min Jeon, Brian K. Paul, Young-Sang Na, Kijoon Lee, Young-Kyun Kim

Journal of Materials Science & Technology.2025; 234: 319. CrossRef

- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

- [English]

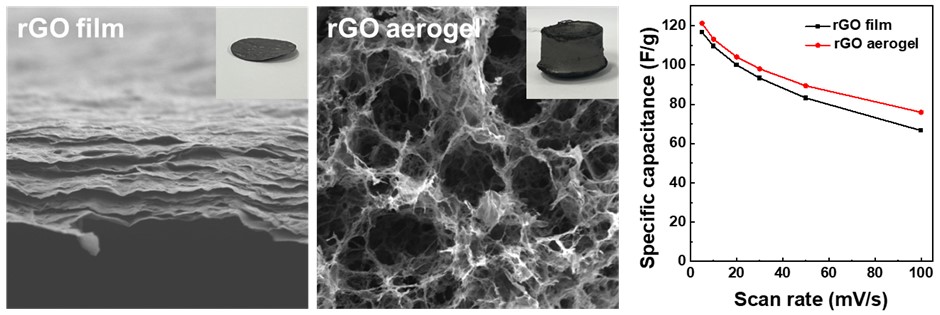

- Comparative Study of Reduced Graphene Oxide Aerogels and Films for Supercapacitor Electrodes

- Sunghee Choi, Seulgi Kim, Seojin Woo, Dongju Lee

- J Powder Mater. 2025;32(1):23-29. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00472

- 1,792 View

- 34 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Supercapacitors, renowned for their high power density and rapid charge-discharge rates, are limited by their low energy density. This limitation has prompted the need for advanced electrode materials. The present study investigated reduced graphene oxide (rGO) in two distinct structures, as a film and as an aerogel, for use as supercapacitor electrodes. The rGO film, prepared by vacuum filtration and thermal reduction, exhibited a compact, lamellar structure, while the aerogel, synthesized through hydrothermal treatment, was a highly porous three-dimensional network. Electrochemical analyses demonstrated the aerogel’s superior performance, as shown by a specific capacitance of 121.2 F/g at 5 mV/s, with 94% capacitance retention after 10,000 cycles. These findings emphasize the importance of structural design in optimizing ion accessibility and charge transfer. They also demonstrate the potential of rGO aerogels for increasing the energy storage efficiency of advanced supercapacitor systems.

-

Citations

Citations to this article as recorded by- Laser-Induced Porous Graphene Electrodes for Flexible Heater

Min Gi An, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 492. CrossRef

- Laser-Induced Porous Graphene Electrodes for Flexible Heater

- [English]

- Design of Conductive Inks Containing Carbon Black and Silver Nanowires for Patternable Screen-Printing on Fabrics

- Seokhwan Kim, Geumseong Lee, Jinwoo Park, Dahye Shin, Ki-Il Park, Kyoung Jin Jung, Yuho Min

- J Powder Mater. 2024;31(6):500-507. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00409

- 2,002 View

- 58 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - This study developed conductive inks composed of carbon black (CB) and silver nanowires (Ag NWs) for cost-effective screen-printing on fabrics. The Ag NW density within the CB matrix was precisely controlled, achieving tunable electrical conductivity with minimal Ag NW usage. The resulting inks were successfully patterned into shapes such as square grids and circles on textile surfaces, demonstrating excellent conductivity and fidelity. Adding 19.9 wt% Ag NWs reduced sheet resistance by ~92% compared to CB-only inks, highlighting the effectiveness and potential of this hybrid approach for cost-effective, high-performance textile-based electronics. The one-dimensional morphology of Ag NWs facilitated the formation of conductive percolation networks, creating efficient electron pathways within the CB matrix even at low loadings. This work advances the field of CB-based conductive inks and provides a scalable and practical method for producing functional, patterned electronic textiles.

-

Citations

Citations to this article as recorded by- Multifunctional Screen-Printed Conductive Inks: Design Principles, Performance Challenges, and Application Horizons

Nahid Islam, Manisha Das, Bashir Ahmed Johan, Syed Shaheen Shah, Atif Saeed Alzahrani, Md. Abdul Aziz

ACS Applied Electronic Materials.2025; 7(16): 7503. CrossRef

- Multifunctional Screen-Printed Conductive Inks: Design Principles, Performance Challenges, and Application Horizons

- [Korean]

- Fabrication and High-Temperature Performance Evaluation of Light-Weight Insulation Materials and Coatings for Reusable Thermal Protection Systems

- Min-Soo Nam, Jong-Il Kim, Jaesung Shin, Hyeonjun Kim, Bum-Seok Oh, Seongwon Kim

- J Powder Mater. 2024;31(6):521-529. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00318

- 1,558 View

- 54 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Light-weight ceramic insulation materials and high-emissivity coatings were fabricated for reusable thermal protection systems (TPS). Alumina-silica fibers and boric acid were used to fabricate the insulation, which was heat treated at 1250 °C. High-emissivity coating of borosilicate glass modified with TaSi2, MoSi2, and SiB6 was applied via dip-and-spray coating methods and heat-treated at 1100°C. Testing in a high-velocity oxygen fuel environment at temperatures over 1100 °C for 120 seconds showed that the rigid structures withstood the flame robustly. The coating effectively infiltrated into the fibers, confirmed by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray diffraction analyses. Although some oxidation of TaSi2 occurred, thereby increasing the Ta2O5 and SiO2 phases, no significant phase changes or performance degradation were observed. These results demonstrate the potential of these materials for reusable TPS applications in extreme thermal environments.

-

Citations

Citations to this article as recorded by- Durability Assessment of Tile-Type Reusable Thermal Protection Materials

Minjeong Kim, Seong Man Choi

Materials.2026; 19(2): 303. CrossRef