Search

- Page Path

- HOME > Search

Research Article

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 551 View

- 32 Download

-

Abstract

Abstract

PDF

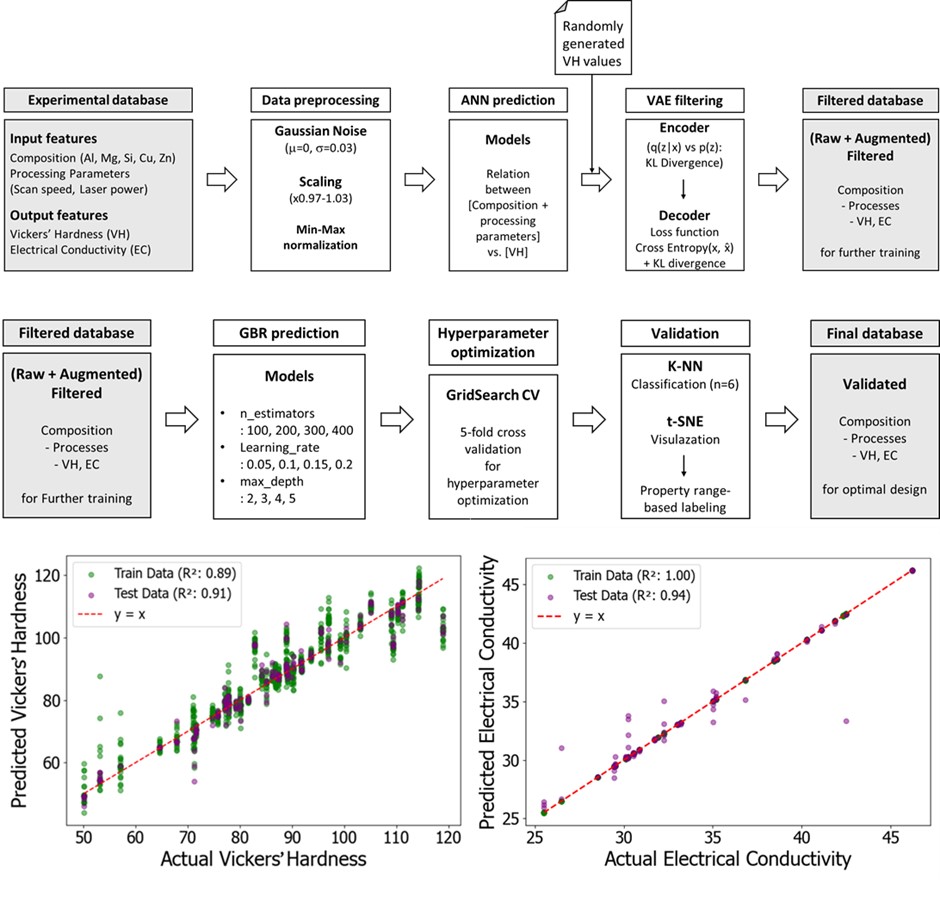

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

TOP

KPMI

KPMI

First

First Prev

Prev