Search

- Page Path

- HOME > Search

Research Article

- [English]

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 1,248 View

- 46 Download

- 3 Citations

-

Abstract

Abstract

PDF

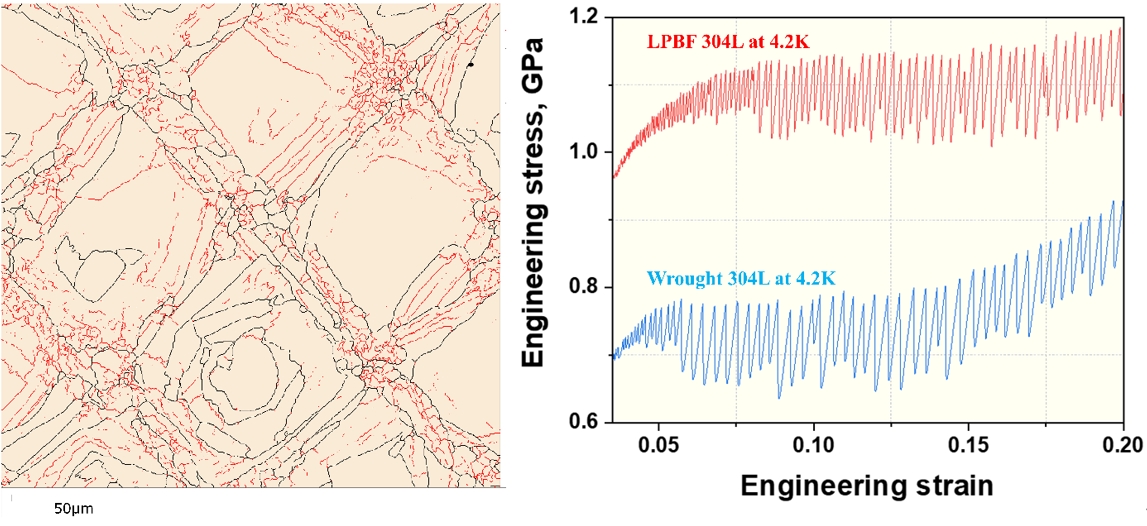

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

Haeum Park, Heechan Jung, Min Young Sung, Young-Kyun Kim, Jaimyun Jung, Yoona Lee, Namhyun Kang, Kyung Tae Kim, Young-Sang Na, Seok Su Sohn, Jeong Min Park

Materials Science and Engineering: A.2026; 950: 149460. CrossRef - Twinning- and transformation-induced high cryogenic strength and ductility of the CoCrFeNi high-entropy alloy: Experiment and MD simulation

Yuze Wu, Zhide Li, Charlie Kong, M.W. Fu, Hailiang Yu

International Journal of Plasticity.2026; 196: 104553. CrossRef - Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

TOP

KPMI

KPMI

First

First Prev

Prev