Articles

- Page Path

- HOME > J Powder Mater > Volume 32(4); 2025 > Article

-

Research Article

열역학 및 열 전달 해석을 활용한 Stellite 6 스크랩 재활용 공정과 분말화 기술 연구 - 이용관1,2,†, 김현철1,2,†, 김명석1,2, 오승주2, 박경태1,*, 심재진1,*

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

- YongKwan Lee1,2,†, Hyun-chul Kim1,2,†, Myungsuk Kim1,2, Soong Ju Oh2, Kyoungtae Park1,*, JaeJin Sim1,*

-

Journal of Powder Materials 2025;32(4):330-343.

DOI: https://doi.org/10.4150/jpm.2025.00136

Published online: August 29, 2025

1한국생산기술연구원 국가희소금속센터

2고려대학교 신소재공학과

1Korea Institute of Industrial Technology, Incheon 21655, Republic of Korea

2Department of Materials Science and Engineering, Korea University, Seoul 02841, Republic of Korea

- *Corresponding Author: Kyoungtae Park and JaeJin Sim E-mail: ktpark@kitech.re.kr and simjae@kitech.re.kr

- †These authors contributed equally to this work.

© The Korean Powder Metallurgy & Materials Institute

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 1,103 Views

- 15 Download

Abstract

- Co-Cr alloys are widely used in cutting tools and turbine components due to their high strength and resistance against wear and corrosion. However, scrap generated during hardfacing is often discarded due to impurities and oxidation, and research on its recycling remains limited. This study aimed to optimize the recycling process of Stellite 6 scrap to reduce waste and minimize costs while maintaining material quality. Melting, casting, and powdering processes were designed using HSC Chemistry, FactSage, and COMSOL Multiphysics, with optimization of key parameters such as the crucible material and temperature control. The recycled alloy and powder were analyzed using X-ray fluorescence analysis, inductively coupled plasma optical emission spectroscopy, and X-ray diffractometry, showing mechanical and chemical properties comparable to commercial Stellite 6. The Co and Cr contents were maintained, with a slight increase in Fe. These findings demonstrate the potential for producing high-quality recycled Stellite 6 materials, contributing to the sustainable utilization of metal resources in high-performance applications.

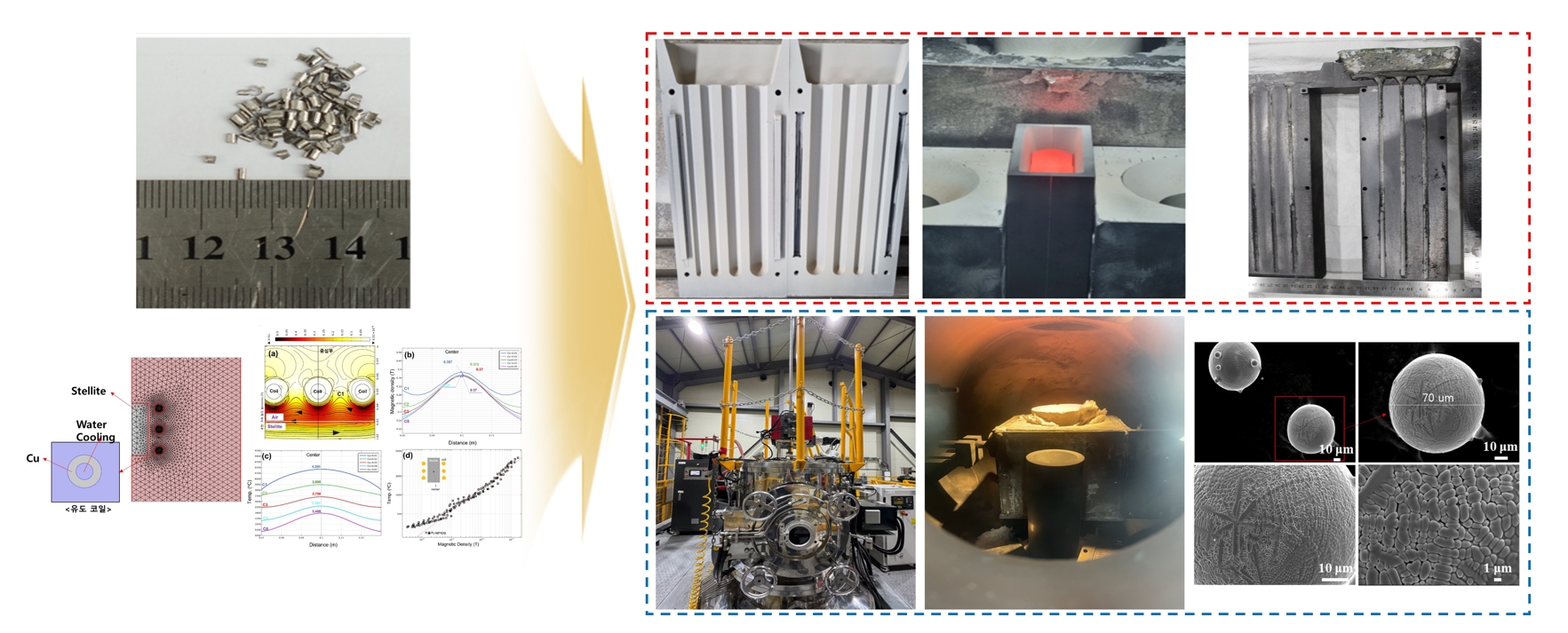

- This study utilized thermal-fluid analysis-based induction melting to recycle Stellite 6 scrap and produced ingots and powder under optimized conditions. The recycled materials exhibited properties comparable to commercial products, demonstrating their potential for reuse as high-performance alloy materials.

Graphical abstract

- Co-Cr계 합금은 높은 강도 (500-1500 MPa), 높은 경도 (HRC 40-65), 그리고 우수한 내마모성과 내식성을 갖는 금속 재료이다[1-5]. 이러한 특성으로 인해 Co–Cr계 합금은 조성에 따라 다양한 형태로 개발되어 절삭 공구, 밸브 부품, 터빈 블레이드, 펌프 부품 등 여러 산업 분야에 널리 활용되고 있다[5–7]. 대표적으로, Co-Cr-Mo계 합금은 내식성 및 생체 적합성이 매우 높아 의료용 임플란트 등 생체 재료 분야에서 주로 사용된다[8-10]. Co-Cr-Ni계 합금은 고온 강도, 내산화성, 내마모성이 우수하여 항공기 엔진, 가스 터빈 등 고온•부식 환경에 적합한 산업용 소재로 활용된다[11, 12]. Co-Cr-W계 합금은 매우 높은 경도와 내마모성 및 내식성 물성으로 인해 하드페이싱 (Hardfacing) 용접 공정의 핵심소재로 활용되며, 특히 Stellite 6 (Kennametal Inc., USA) 라는 제품으로 가장 널리 알려져 있다[13-15].

- 이처럼 다양한 산업 분야에서 활발히 활용되는 Stellite 6을 기반으로, 많은 연구자들이 모재의 특성 향상 및 고온 환경에서의 코팅 효과 증진을 위한 연구를 수행해왔다. Jacek Górka et al. [16]은 Laser-Cladded Coatings 공정을 통해 Co 기반 합금(Stellite 6)에 경도와 미세구조를 개선 효과가 있는 타이타늄 카바이드 (TiC) 형성을 위해 다양한 농도의 Ti와 C를 첨가하여 내식성 향상 증진 및 침식 저항성 향상을 위한 연구를 수행하였다. 그 결과, Ti–W–C 복합 탄화물이 형성되어 소재의 마모 및 변형 저항성을 증가시켰으며, 이에 따라 모재의 내식성과 침식 저항성이 향상됨을 확인하였다. 또한, Dariusz Bartkowski et al. [17]은 다양한 WC, TiC 비율과 레이저 빔 출력에 따른 코팅 효과를 비교 분석하여, 생성된 탄화물로 인해 미세경도와 내마모성이 향상되며 모재의 침식 저항성과 내구성 역시 개선됨을 확인하였다.

- Eyup Bagci et al. [18, 19]은 Stellite 6 합금의 페이스 밀링 (face milling) 공정에서 공구 마모, 칩 형상, 절삭력 변화가 모재의 제거율 (Material Removal Rate, MRR) 및 마모 특성에 미치는 영향을 체계적으로 분석하였다. 그 결과, 절삭 깊이 및 이송 속도에 따라 절삭력이 증가함에 따라 내식성이 향상되는 경향을 보였으며, 절삭 속도와는 유의한 상관관계가 확인되지 않았다. 그리고, Joowon Suh et al. [20]은 지향성 에너지 적층 (Directed energy deposition, DED) 기반 적층 제조에 열간 등압 성형 (Hot Isostatic Pressing, HIP) 공정을 결합한 후처리 방법을 통해, 기존 주조 공정 대비 코발트 기지상의 감소 및 탄화물 형성이 경도 등 기계적 특성 향상에 기여하며, 결과적으로 내식성이 개선됨을 입증하였다.

- 뿐만 아니라, Stellite 6은 분말 형태로 열 스프레이 코팅, 고속 산소 연료 분사 (High Velocity Oxygen Fuel, HVOF) 공정에도 많이 활용되고 있다. 이와 관련하여 Alejandra Islas Encalada et al. [21]은 Stellite 6 분말에 탄화 크로뮴 (Cr3C2) 금속 바인더를 첨가하여 HVOF 공정을 수행함으로써, 마모 저항성 향상과 그 메커니즘에 대한 연구를 진행하였다. 해당 연구에서는 마모 특성에 중요한 영향을 미치는 Cr₃C2의 장입을 통해 코팅 물성이 개선됨을 입증하였다. 또한, Žaneta Dlouhá et al. [22]는 탄소강 및 질화강 기판에 Stellite 6을 코팅하기 위해, HVOF 공정 전 레이저 텍스처링 (Laser Texturing) 전처리 공정을 적용하여 코팅 효율을 분석하였다. 그 결과, 탄소강에서는 기계적 고정력 (mechanical interlocking) 향상으로 인해 코팅 효율이 증가한 반면, 질화강은 표면의 얇고 취성 있는 질화층이 레이저 텍스처링 및 HVOF 분사 중 손상되어 계면에 크랙이 발생하였고, 이로 인해 코팅 성능이 저하됨을 확인하였다."

- 이처럼 Stellite 6 및 분말을 활용한 모재 특성 향상과 코팅 성능 개선에 관한 연구는 활발히 진행되고 있으나, 하드페이싱 공정 중 발생하는 Stellite 6 스크랩의 재활용에 대한 연구는 아직 미흡한 수준에 머물고 있다. Stellite 6 스크랩은 금속 산화물, 절삭유 등의 불순물이 혼입될 가능성이 높아 대부분 폐기되며, 이에 따른 경제적 손실과 자원 낭비가 발생하고 있다. 스크랩을 효과적으로 재활용할 경우 원자재 비용 절감뿐만 아니라 공정에서 소요되는 총 에너지 및 비용까지 절감할 수 있을 것으로 기대된다.

- 따라서, 본 연구에서는 Stellite 6 스크랩의 재활용 가능성을 검토하고, 스크랩 내 일정량의 기재가 포함된 경우에도 실용적인 재활용이 가능한지를 검토하고자 한다. 이를 위해 다양한 시뮬레이션 소프트웨어 (HSC Chemistry [23], FactSage 8.0 [24], COMSOL Multiphysics 6.1 [25])를 활용하여 재활용 공정을 최적화하고, 실제 산업 현장에서 발생한 Stellite 6 스크랩을 기반으로 재활용 Stellite 6 주조재를 제조하였다. 또한, 제조된 재활용 Stellite 6 주조재를 활용하여 열 스프레이 코팅 및 HVOF 사용 가능한 분말을 제조하였고, 최종적으로 재활용 소재의 물성 특성을 분석하여 상업용 Stellite 6 제품과 비교 분석함으로써 재활용 공정의 상업적 활용 가능성을 평가하였다.

1. Introduction

- 2.1 실험 방법

- 본 연구에서는 Stellite 6 스크랩의 재활용을 위한 최적의 공정을 도출하기에 앞서, 다양한 전처리 및 분석을 수행하였다. 실험에 사용된 스크랩은 ㈜삼신에서 발전소용 밸브 용접 공정 이후 실제로 발생한 산업용 Stellite 6 스크랩을 제공받아 활용하였다. 스크랩 내에 잔류된 절삭유 및 기타 유기 용매와 같은 다양한 불순물을 제거하기 위해 에탄올을 활용한 Ultrasonic 3시간을 진행하였다. 그 후 불순물이 제거된 스크랩의 밀도 향상을 위해 Vacuum-plasma melting 및 프레스 공정을 통한 Compaction을 진행하였다.

- 그 다음으로 Stellite 6 스크랩 재활용 공정 최적화를 위해 HSC Chemistry 8.0과 FactSage 8.0 Software를 활용하여 열역학적 계산을 수행하고, 이를 바탕으로 다양한 공정 조건을 도출하였다. 그리고 COMSOL Multi-physics Software를 이용한 유한요소해석 (Finite element method, FEM)을 통해 열 전달 및 물리 전산모사 계산을 진행하여 고주파 용해 조건을 선정하였다.

- 선정된 공정 조건을 기반으로 전처리된 스크랩 원료와 고주파 유도 용해 장비를 이용하여 Stellite 6 스크랩 용해 공정을 수행하였으며, 생성된 용탕을 제조한 몰드에 주조한 후, 4시간 냉각 과정을 거쳐 최종 제품을 회수하였다. 회수된 최종 제품에 대한 XRF, ICP-OES, FE-SEM, EDS, XRD 분석을 수행하였고, 상용 Stellite 6 제품의 물성과 비교하였다. 그리고, 제조한 재활용 Stellite 6 주조재와 아토마이저 공정을 통해 Stellite 6 분말을 제조하였다. 이후, 체질 공정을 통해 입자 크기별로 분리한 후, 다양한 기초 분석을 수행하여 상업용 분말과 비교 평가를 진행하였다. 최종적으로 제조된 재활용 Stellite 6 분말을 다양한 기초분석을 통해 상용 분말과의 물성 평가를 진행하였다.

- 2.2 특성 평가

- 본 연구를 통해 제조된 Stellite 6 주조재 및 분말의 성분분석을 위해 Energy Dispersive Sepctroscopy (EDS) (Oxford, U.K사), ICP-OES (Inductively Coupled Plasma – Optical Emission Spectroscopy, Varian Vista Pro, USA), X-ray Fluorescence Analysis (XRF) (Thermo Fisher SCIENTIFIC, ARL PERFORM’X, USA)을 활용하여 진행하였다. 또한, 구조분석은 Field Emission Scanning Electron Microscope (FE-SEM) (JEOL사, Model: JSM-7100F), X-Ray Diffractometer(XRD) (BRUKER AXS사, Model: D8 ADVANCE)을 활용하여 특성 평가를 진행하였다.

2. Experimental Section

- 3.1 열역학적 계산 결과

- 본 실험에 앞서 Stellite 소재의 열역학적 거동을 파악하기 위하여, FactSage 8.0 Software의 Phase Diagram 모듈을 활용해 시뮬레이션을 수행하였다. 두 가지 상태도 계산을 진행하였으며, 이는 Fig. 1에 제시하였다. Fig. 1 (a)는 Stellite 합금의 주요 기지인 Co-Cr 이원계 상태도로, 다양한 Co/Cr 조성비와 온도 조건에서의 상변화를 확인을 위한 상태도 계산 결과이다. 계산 결과에 따르면, Co 함량에 따라 α-Co (고온상), ε-Co (저온상), σ상, 그리고 액상 (Liquid)이 형성되는 것을 확인할 수 있다. 특히, α-Co 및 ε-Co 상은 Cr이 최대 40%까지 고용이 가능하고 σ상은 국부적인 Co 결핍 상태에서 석출된다고 알려져 있으며, 이는 Stellite 6 합금의 내부식성 저하와 연관이 있는 것으로 알려져 있다[20].

- Fig. 1 (b)는 다성분계 Stellite 6 합금에 대해 Cr 함량 및 온도에 따른 상평형 변화를 계산한 결과를 나타낸다. 계산 결과, 다양한 고상 및 탄화물 상이 존재하는 것으로 확인되었다. 또한, 상태도 내에 표시된 빨간색 범위는 상용 Stellite 합금에서 일반적으로 보고되는 Cr 함량 (약 25–30 wt%)을 반영한 것으로, 주요 합금 원소 (Co, Cr, W, Fe, Si 등)의 상대적 원자비 기준으로 환산할 경우 이 범위가 약 0.2–0.3의 조성 구간에 해당하므로 이를 적용하였다. 해당 조성 영역에서는 온도에 따라 탄화코발트 (CoxWγCa) 및 복합 탄화물 상이 형성될 가능성이 있음을 시사한다. 마지막으로, Stellite 6 스크랩 재활용 시 σ상 형성과 Cr 탄화물 침전 방지를 위해서는, Co-Cr 기지 내 완전 용해 조건을 확보할 필요가 있으며, 이때 최소 1,500 ℃ 이상의 고온 조건이 요구된다는 결론을 도출하였다.

- 그리고 Stellite 6 스크랩의 재활용 공정에서 사용될 도가니 소재를 선정하기 위해, HSC Chemistry Software를 활용하여 다양한 후보 소재와의 반응성 계산을 진행하였으며 원료 및 도가니와의 반응으로 인한 생성물은 그래프 내 붉은색 글씨로 표시하여 강조하였다. Fig. 2 (a)는 일반적으로 많이 사용되는 금속 도가니 소재와의 반응성 계산 결과를 나타내었다. 그 결과, 몰리브덴 (Mo), 티타늄 (Ti), 탄탈륨 (Ta)은 고온 공정 조건에서 원료 성분들과 반응하여 각각 이몰리브덴 (Mo2), 크로뮴화 티타늄 (TiCr2), 크로뮴화 탄탈럼 (TaCr2) 등의 화합물을 형성하는 것이 확인되었다. 반면, 텅스텐(W)과 지르코늄(Zr)은 원료와 반응하지 않는 것으로 나타나, 금속 도가니 소재로서 W 및 Zr이 적합한 후보로 판단되었다.

- Fig. 2 (b)는 다양한 세라믹 도가니 소재와의 반응성을 계산한 결과이며, 대부분의 세라믹 소재는 원료와 반응하여 여러 생성물이 형성되는 것으로 확인하였다. 생성물 확인이 어려운 소재의 경우, 그래프를 확대하여 추가로 제시하였으며, 그 중 지르코니아 (ZrO2)는 예외적으로 원료와 반응하지 않고 안정한 거동을 나타내어, 세라믹 소재 중 가장 적합한 도가니 재료로 판단됩니다. 결론적으로, 용해 공정에서 도가니 소재로는 금속의 경우 W 또는 Zr, 세라믹의 경우 ZrO2가 활용 가능함을 확인하였다.

- 3.2 열 전달 해석 결과

- 다음은 Stellite 6 스크랩 재활용 공정에 활용된 고주파 유도가열 공정 조건 설정을 위해 COMSOL Multiphysics software를 활용하여 열 전달 해석을 진행하였으며 이때 활용된 메시 단면은 아래 Fig. 3에 나타내었다. 또한 활용된 지배방정식은 아래 Eq. (1)에 나타낸 내부 열에너지 변화 (ρCp∙∂T/∂t + ρCp∙∇T)는 내부 발생 열에너지 ∇∙(k∇T) 및 외부 전자기장 열에너지 (Qe) 온도변화로 계산하고 발산 및 내부로 전달되는 에너지 변화는 밀도에 따른 온도전달현상을 고려해서 열 전달 계산을 실시하였다. 이때 활용된 Stellite 소재의 물성 데이터베이스는 아래 Table 1에 나타내었다. 또한, 외부에 인가되는 전자기유도에 의한 열에너지 부여는 자기장에 의한 열원과 전기장에 의한 열원으로 나눠서 계산하고, 이에 대한 수식 설명은 아래 Eq. (2-4)에 나타내었다.

- ρ : Density

- Cp: Heat capacity

- k: Thermal conductivity

- T: Temperature

- ▽: Gradient

- Qe: External heat source

- Qrh: Ohmic heating

- Qml: Induction heating

- R: Coil diameter

- e−iωB: Exponentially Decaying Term

- ω: Angular frequency

- B: Magnetic field

- eE: Heat generation function

- 다음과 같은 데이터 베이스를 활용하여 첫번째로, 출력 변화에 따른 자기장 밀도 계산을 진행하였다. 이때 주파수는 보유한 고주파 공정 장비의 가동 출력인 3 kHz에서 다양한 출력 조건 별 자기장 변화 및 밀도가 어떻게 형성되는지 계산을 진행하였다. 그 결과 Fig. 4 (a)에서 확인되는 것처럼 출력이 증가함에 따라 자기장의 세기가 0.02에서 0.08 T까지 증가됨을 확인하였다. 이때, 표시된 T는 각 출력에서 발생하는 자기장의 세기를 의미하며 5 kW 이상의 경우 강한 자기장이 발생하여 소재 용해에 필요한 최소 온도인 1,500 ℃ 이상의 온도 상승을 위해 최소 5 kW 이상의 코일 전력이 요구된다고 판단된다.

- Fig. 4 (b)는 최적 출력 조건인 3 kHz 5 kW 조건에서 시간에 따른 소재 내부 온도 변화 시뮬레이션 결과를 나타내었다. 첫 번째 이미지는 0초 경과 시점에서 온도가 매우 낮은 상태(파란색)가 나타남이 확인되며 960초가 지나면 소재 내부가 서서히 가열되면서 온도가 상승하고, 2,880초와 3,600초에서는 내부 온도가 약 1900°C 이상으로 높아져, 최종적으로 온도 분포가 붉은색으로 표시되며 온도 최고치에 도달하였다고 판단된다.

- 다음으로, 동일한 3kHz 주파수에서 코일 전력에 따른 온도 분포 시뮬레이션 결과를 아래 Fig. 5에 나타내었다. 계산 결과 2.0 kW 이상의 전력조건에서 소재 용융이 가능했지만 수 시간이 소요됨을 확인할 수 있다. 반면 5 kW 이상 조건에서는 30분 미만으로 용해가 가능하여 출력 별 자기장 발생 세기 계산 결과와 동일하게 코일 전력이 최소 5 kW 이상 조건이 적절하다 판단된다.

- 위 열 전달 해석 결과에서 소재의 용융에 필요한 최소 조건이 3kHz - 5kW으로 도출되었으나 같은 전력 조건이라 하여도 유도 코일 조건 (간격) 및 소재의 국부 위치에 따라 자속밀도 및 온도 차이가 나타날 수 있다. 또한, 용융 시 상하좌우 간 온도 편차가 심하면 전체적인 가열을 위해 많은 열량이 필요하고 용해 시간이 길어질 수 있다. 최적의 코일 조건을 도출하기 위해 COMSOL multi-physics Software의 유한요소해석 (FEM) 법으로 자속 밀도 및 온도 구배 계산을 진행하였다. 이때, 고주파 열 전달 계산에 활용된 출력 조건 및 코일 간격 조건은 Table 2에 나타냈으며 시뮬레이션 결과는 아래 Fig. 6에 나타내었다.

- 그 결과 Fig. 6 (a)는 코일 (C1 조건) 주변의 자속밀도 분포를 보여주며 색에 따른 자기장의 세기 확인이 가능하다. 이를 기반으로 (b)는 코일 간격에 따른 자기 밀도 변화 그래프 계산 결과이며, (c)는 코일 간격 별 온도 변화 확인을 위한 계산 결과이다. 계산 결과 코일 간격이 가장 가까운 C1 조건에서 최대 온도 (4,200 ℃)와 중심부에 가장 높은 자속밀도 (0.387 [T])를 지닌 것을 확인하였다. 또한, (d)는 Stellite 6 중심부 기준으로 모든 코일 간격 (C1-C5) 및 모든 시간 (0–50 min)을 자속밀도(X)/온도(Y)에 대하여 플롯 하였을 때, 약 167 °C/Guass의 기울기로 선형 비례하는 결과를 확인하였다. 이는 코일 간격과 관계없이 본 공정조건 (주파수 3 kHz, 코일전력 53 kW)에서는 Y=167X-10 (Y: 온도 [℃], X: 자속밀도 [Gauss])의 관계가 있음을 도출하였다.

- 3.3 Stellite 6 스크랩 재활용 공정 주조재 분석 결과

- 앞선, 열역학 및 열 전달 해석을 통해 선정한 Stellite 6 스크랩 재활용을 위한 고주파 용해 공정을 진행하였다. 먼저, 아래 Fig. 7 (a)는 본 공정에 실제로 활용된 Stellite 6 스크랩이며, (b)는 금속 도가니 대비 경제적 효율이 높은 세라믹계 도가니 중 Al2O3 도가니를 활용하였고 이때, 열역학 계산 결과 고온에서 원료와의 반응이 일어나지 않는 지르코니아 (ZrO2) 성분의 이형제를 도포한 몰드를 활용하였다. 그리고, 열 전달 해석 결과 최적 공정 조건인 3 kHz-53 kW, 코일 간격 0.01 m 조건으로 스크랩이 완전히 용해될 때까지 약 30분정도 공정을 진행하였고 용해된 주조재를 (c)와 같이 제작한 세라믹 몰드 내 주입한 후 최종적으로 회수한 재활용 Stellite 6 주조재는 Fig. 7 (d)에 나타내었다.

- 최종적으로 회수한 주조재의 주요 및 불순물 성분을 확인, 상용 Stellite 6와의 성분 비교를 위해 XRF 및 ICP-OES 분석을 수행하였으며, 그 결과를 아래 Fig. 8에 나타내었다. Co 및 Cr 성분 비율 (Co/(Co+Cr)%)을 계산한 결과, XRF 분석 결과는 64.35% (50.9/(50.9+28.2)), ICP-OES 분석 결과는 64.22% (49.9/(49.9+27.8))로 측정되었다. 이는 원료로 사용된 용접봉 (64.66%) 및 스크랩 (64.07%)과 유사한 수준을 유지함을 나타낸다. 또한, 기타 합금 원소 (Fe, W, Ni 등)도 원료와 비교하여도 큰 차이가 나타나지 않았다.

- 그러나, Fe 성분의 함량은 원료로 활용된 스크랩 내 12.01%와 유사한 12.5~13.2%가 검출됨을 확인하였다. 이는 철강 산업에서 공정 후 발생하는 스크랩을 활용하였으므로 공정 중 Fe이 많이 유입되어 상용 Stellite 6 (평균 Fe 함량 5~10%)에 비해 높은 Fe 함량이 검출되었다고 사료된다. Stellite 6 내 과량의 Fe의 함량은 탄화물 감소에 영향을 주어 Stellite 6의 경도를 감소시킨다고 알려져 있다[26]. 따라서, 이는 향후 추가적인 공정 (진공증류 등)을 통한 후처리 공정 최적화 및 소재 고순도화 연구를 진행할 예정이다.

- 재활용 Stellite-6 주조재의 결정상 분석 결과, Peak의 위치는 일정하게 유지되었으나, Intensity 강도의 순서가 바뀐 것이 확인되며 이는 완전 용해 후 응고되면서 생긴 배향성과 Fe 성분의 portion 증가로 인해 이러한 현상이 발생되었다고 판단된다.

- 다음으로, 재활용 Stellite 6 주조재의 미세조직 비교를 위한 상용 Stellite 6, 스크랩, 재활용 Stellite 6 주조재 FE-SEM 분석을 진행하였으며 그 결과는 아래 Fig. 10에 나타내었다. 그 결과, 내부 미세조직으로는 전형적인 주조 조직이 관찰되었으며 레퍼런스 (Reference) 소재의 미세구조와 유사한 구조를 보였다. 또한, 상용 Stellite 6에서 스크랩화 시 확인되지 않은 배향조직이 재활용 Stellite 6에서 재형성되었으며, 조대화된 결정립도가 감소됨을 확인하였다[5, 27]. 이를 통해 상용 Stellite 6와 유사한 내부 미세조직을 가진 재활용 Stellite 6 주조재가 회수됨을 입증하였다.

- 3.4 Stellite 6 재활용 분말 분석 결과

- 먼저, 상용 stellite 6 분말의 형상 및 성분 확인을 위한 FE-SEM, EDS 분석 결과를 아래 Fig. 11에 나타내었다. Fig. 11 (A)에서 확인되듯이 상용 Stellite 6 분말의 형상은 응고 조직상을 가진 구형 입자들로 구성되어 있음을 확인하였다. 그리고 (B)에 나타낸 EDS 분석 결과 주된 성분인 Co-Cr 합금의 성분이 검출되었으며, 추가적으로 W, Si, Zr 성분도 검출됨을 확인하였다.

- 앞서, 제조한 재활용 Stellite 6 주조재와 아토마이저 공정을 활용하여 HVOF 공정용 Stellite 6 분말을 제조하였고 아토마이저 장비 및 공정도는 아래 Fig. 12에 나타내었다. 그리고 본 연구에 활용된 아토마이저 공정은 장비 최대 전력인 23 kW에서 진행하였고 노즐 타입, 오리피스 직경, 분사 가스 및 압력 등 아토마이저 상세 공정 조건은 아래 Table 3에 나타내었다.

- 앞서, 공정 최적화를 통해 제조한 Stellite 6 스크랩 재활용 주조재를 활용한 아토마이저 공정을 통해 분말 제조 공정을 진행하였고, 제조된 분말을 분급 공정을 통해 입자 크기별로 분리한 후, 각 크기별로 물성 확인을 위한 다양한 기초분석을 진행하였다. Fig. 12에서 확인할 수 있듯이 XRD 분석 결과 주 성분인 Co, Cr 결정상이 검출되었으며, 입자 크기 별 큰 차이가 나타나지 않음을 확인하였다.

- 그러나, Fig. 9에 나타낸 재활용 Stellite 6 주조재의 Cr 및 Co의 XRD Peak 위치와 Fig. 13에 나타낸 재활용 Stellite 6 분말의 Cr 및 Co Peak 위치가 서로 다르게 검출됨을 확인하였다. 이러한 차이는 가스 아토마이징 공정 중 고속 응고 및 급격한 열 수축으로 인해 격자 내 응력이 잔류하게 되고, 이는 격자 상수의 변화를 유발하여 XRD 피크의 위치 이동 (peak shift)을 초래할 수 있다고 알려져 있다[28]. 특히 Co–Cr 계 합금은 Co (1.26 Å)와 Cr (1.27 Å) 간의 미세한 원자 반경 차이에도 불구하고 격자 왜곡에 민감하게 반응하는 특성을 가지는 것으로 알려져 있다[29]. 또한, Jitesh Kumar et al.[30]은 Co–Fe–Ni 계 합금에 Cr이 첨가되면 격자 내 왜곡(lattice distortion)이 증가하고, 이는 고용 강화 (solid solution strengthening) 효과를 유발한다고 보고된 바가 있다. 종합적으로 볼 때, 이러한 잔류응력에 기인한 격자 변형으로 인해 Co 및 Cr의 XRD 피크 위치가 변위 되었으며, 이에 따라 Fig. 9와 Fig. 13에서 상이한 피크 위치가 관찰된 것으로 판단된다.

- 다음으로, Fig. 14는 입자 크기 별 FE-SEM, EDS 분석 결과이며, 상용 분말과 동일하게 응고 조직상 및 구형 입자를 가진 분말이 제조됨을 확인하였다. 또한, EDS 분석 결과 XRD와 동일하게 주로 Co, Cr 성분이 검출됨을 확인하였으며, W, Si, Fe 역시 일부 검출됨을 확인하였다. 추가적으로, 재활용 Stellite 6 주조재를 분말화 한 후 Fe 함량이 감소하는 경향이 확인되었다. 이러한 결과는 다음과 같은 원인에 기인한 것으로 사료된다. 첫번째로 분사 가스 압력이 증가하면 평균 입자 크기가 감소하고, 이에 따라 단위 질량당 표면적이 증가하여 산화 반응이 발생할 수 있는 면적이 확대되는 효과로 인해 Fe가 산화되었을 가능성이 높을 것으로 판단된다. 또한, 아토마이징 공정 시 높은 가스 분압은 분말의 비행 거리를 증가시키며, 이로 인해 고온 노출 시간이 길어져 산화도가 더욱 높아지는 것으로 보고되고 있다[31]. 이러한 현상으로 인해 Fe가 산화되어 미세 산화물 형태로 분리되거나 혹은 응고되기 전에 분말로 수거되지 않고 챔버 내에 증착 되었기 때문에 재활용 Stellite 6 분말 내 Fe 함량이 감소되었다고 판단된다. 그리고 일부 Fe가 액적 표면에 농축된 후 슬러지 또는 분진 형태로 분리되었을 가능성도 있다고 판단된다[32]. 따라서 본 연구를 통해 상용 Stellite 6 분말과 유사한 물성을 가진 재활용 분말이 제조됨을 확인하였다.

3. Results and Discussion

3.2.1 고주파 유도가열 공정 조건 확립을 위한 열 전달 해석 결과

- 본 연구에서는 Stellite 6 스크랩의 재활용 공정을 통해 고순도 Stellite 6 주조재 및 분말을 제조하고, 그 물성을 상용 제품과 비교하여 재활용 공정의 타당성과 상업적 활용 가능성을 평가하였다.

- 1. 다양한 소프트웨어를 활용하여 열역학적 계산과 열 전달 해석을 통해 최적의 재활용 공정 용해 및 주조 조건을 도출하였다. 도가니 소재로 W, Zr, ZrO2이 적합함을 확인하였고 경제성과 반응 안정성을 고려하여 Al2O3 내 ZrO2를 도포한 도가니를 활용하였다. 그리고 열 전달 해석 결과를 바탕으로 주파수 3 kHz, 코일 가동최대 전력인 53 kW, 코일 간격 0.01 m 공정 조건에서 고순도 재활용 Stellite 6 주조재를 성공적으로 제조하였다.

- 2. 최종적으로 제조된 재활용 Stellite 6 주조재의 성분 및 미세조직 분석 결과, 상용 Stellite 6과 유사한 특성을 보였으며, Fe 함량은 스크랩 특성상 소폭 증가하였다. 이는 향후 공정 개선 혹은 추가적인 후처리 공정을 통한 불순물 제어 연구를 진행할 예정이다.

- 3. 또한, 고순도 재활용 Stellite 6 주조재 및 아토마이저 공정을 활용하여 제조된 재활용 Stellite 6 분말의 다양한 물성 분석 결과를 통해 상용 분말과 유사한 입자 형상, 조직, 조성을 가진 분말이 제조됨을 확인하였다.

- 따라서 본 연구는 산업 현장에서 발생하는 Stellite 6 스크랩을 고부가가치 소재로 재활용할 수 있는 실질적인 공정 가능성을 제시하였으며, 이는 금속 폐기물 저감과 원자재 비용 절감 측면에서 지속 가능한 소재 활용 방안을 제공한다. 앞으로는 본 연구 결과를 기반으로 기계적 성능 및 내마모성 평가를 통해 산업 적용 범위를 확대하고, 공정 최적화 및 후처리 기술 개발을 통한 소재 고순도화 연구를 지속할 예정이다.

4. Conclusion

-

Funding

This study was supported in part by the internal research project of Korea Institute of Industrial Technology (Project No. EM220006, Development of material preparation/surface treatment/post-processing for molten metal-based hard-facing technology with higher than 40 HRC hardness) and by the government and local government-funded commissioned project (Project No. IZ250036, Development of TiC self-propagating high-temperature synthesis manufacturing process technology to develop advanced electrostatic chuck for semiconductor wafer fixation).

-

Conflict of Interest

The authors declare no conflict of interest.

-

Data Availability Statement

All dataset files used in this study can be available on request.

-

Author Information and Contribution

YongKwan Lee: Ph.D. Candidate; conceptualization, Investigation, Visualization, writing - original draft, Data curation, Software Hyun-chul Kim: Ph.D. Candidate; conceptualization, Investigation, Visualization, writing - original draft, Data curation, Software Myungsuk Kim: Ph.D. Candidate; Formal analysis, Data curation, Investigation Soong Ju Oh: Professor; Investigation, Conceptualization, Validation, Writing - Review & Editing Kyoungtae Park: Principal Researcher; Investigation, Conceptualization, Validation, Supervision, Project administration, Funding acquisition, Writing-Original Draft, Writing - Review & Editing JaeJin Sim: Senior Researcher; Investigation, Conceptualization, Validation, Supervision, Project administration, Writing-Original Draft, Writing - Review & Editing

-

Acknowledgments

None.

Article information

| Parameter | Value |

|---|---|

| Power [kW] | 23 |

| Vacuum level of vacuum chamber [Torr] | 9.0*10-2 |

| Nozzle type | Direct injection type |

| Orifice diameter [mm] | 4 |

| Atomizing gas | Ar |

| Atomizing pressure [bar] | 25 |

- 1. A. Shahroozi, A. Afsari, B. Khakan and A. R. Khalifeh: Surf. Coat. Technol., 350 (2018) 648.Article

- 2. B. Venkatesh, K. Sriker and V. S. V. Prabhakar: Procedia Mater. Sci., 10 (2015) 527.Article

- 3. W. C. Lin and C. Chen: Surf. Coat. Technol., 200 (2006) 4557.Article

- 4. A. Motallebzadeh, E. Atar and H. Cimenoglu: Tribol. Int., 91 (2015) 40.Article

- 5. Z. Li, Y. Cui, J. Wang, C. Liu, J. Wang, T. Xu, T. Lu, H. Zhang, J. Lu, S. Ma, H. Fan and S. Tang: Metals, 9 (2019) 474.Article

- 6. V. Kuzucu, M. Ceylan, H. Celik and I. Aksoy: J. Mater. Process. Technol., 69 (1997) 257.Article

- 7. F. Brownlie, T. Hodgkiess, A. Pearson and A. M. Galloway: Wear, 376 (2017) 1279.Article

- 8. M. X. Yao, J. B. C. Wu and Y. Xie: J. Mater. Chem. A, 407 (2005) 234.Article

- 9. K. Vutova, V. Stefanova, V. Vassileva and S. A. Vladimirova: Metals, 15 (2022) 4168.Article

- 10. P. S. N. Mendes, J. F. C. Lins, P. S. N. Mendes, W. R. Prudente, R. P. Siqueira, R. E. Pereira, S. M. S. Rocha and A. R. Leoni: Int. J. Eng. Res. Appl., 7 (2017) 34.

- 11. R. R. Garbade and N. B. Dhokey: IOP Conf. Ser.: Mater. Sci. Eng., 1017 (2021) 012033.ArticlePDF

- 12. T. Matkovic, P. Matkovic and J. Malina: J. Alloys Compd., 366 (2004) 293.

- 13. N. Thawari, C. Gullipalli, J. K. Katiyar and T. V. K. Gupta: MSEB., 263 (2021) 114799.Article

- 14. J. C. Shin, J. M. Doh, J. K. Yoon, D. Y. Lee and J. S. Kim: Surf. Coat. Technol., 166 (2003) 117.Article

- 15. Z. Hu, D. Zhanga, D. Wub, X. Zhenga, J. Sun, P. Geng and N. Ma: Surf. Coat. Technol., 478 (2024) 130447.

- 16. J. Gorka, T. Poloczek, D. Janicki, A. Lont, S. Topor, M. Zuk and A. Rzeznikiewicz: Materials, 17 (2024) 3101.Article

- 17. D. Bartkowski, A. Bartkowska, J. Olszewska, D. Przestacki and D. Ulbrich: Materials, 16 (2023) 5000.Article

- 18. E. Bagcı and S. Aykut: Arabian J. Sci. Eng., 39 (2014) 8135.Article

- 19. E. Bagcı and S. Aykut: Int. J. Adv. Manuf. Technol., 29 (2006) 940.ArticlePDF

- 20. J. W. Suh, J. H. Koh, Y. B. Chun, Y. D. Kim, J. S. Jang, S. H. Kang and H. N. Han: J Powder Mater., 31 (2024) 152.ArticlePDF

- 21. A. I. Encalada, S. A. Alidokhta, P. Stoyanov, M. Makowiec, C. Moreau and R. R. Chromik: Wear, 546 (2024) 205310.Article

- 22. Ž. Dlouhá, J. Duliškovic, M.F. Netrvalová, J. Nad’ová, M. Vostrák, S. Kraft, U. Löschner, J. Martan and Š. Houdková: Metals, 17 (2024) 5069.Article

- 23. HSC Chemistry Software Ver. 8.0. https://www.outotec.com, 2018

- 24. FactSage Software Ver 8.0. http://www.factsage.com/, 2021

- 25. COMSOL Multiphysics® v6.1, Heat Transfer Module, COMSOL AB, Stockholm, Sweden (2022).

- 26. M. A. Baek, G. B. Kang, G. C. Suk, S. C. Hong, Y. D. Kim and T. W. Na: Metals, 14 (2024) 244.Article

- 27. A. Shahroozia, A. Afsarib, B. Khakana and A. R. Khalifeh: Surf. Coat. Technol., 350 (2018) 648.Article

- 28. M. Belassel: SAE Int. J. Mater. Manuf., 5 (2012) 352.Article

- 29. H. F. Zhang, H. L. Yan, H. Yu, Z. W. Ji, Q. M. Hu and N. Jia: J. Mater. Sci. Technol., 48 (2020) 146.Article

- 30. J. Kumar, M. Radhakrishnan, S. Palaniappan, K. M. Krishna, K. Biswas, S. Srinivasan, R. Banerjee and N. B. Dahotre: Mater. Today Commun., 40 (2024) 109485.Article

- 31. Y. Shi, W. Lu, W. Sun, S. Zhang, B. Yang and J. Wang: J. Mater. Sci. Technol., 105 (2022) 203.Article

- 32. S. Yu. Manegin, S. D. Rozanov, I. A. Gulyaev, A. V. Mezhevov and P. O. Zhukov: J. Met., 66 (2022) 61.ArticlePDF

References

Figure & Data

References

Citations

Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Fig. 12.

Fig. 13.

Fig. 14.

Graphical abstract

| Material Properties | Air | Water | Copper | Stellite |

|---|---|---|---|---|

| Density (Kg/m3) | 1,900 | 5,200 | 8,940 | 7,760 |

| Thermal conductivity (W/m*K) | 0.3 | 1,000 | 400 | 22.5 |

| Specific heat capacity (J/Kg*K) | 1,369 | 5,200 | 385 | 610 |

| Electrical conductivity (S/m) or Electrical resistivity (ohm*m) | 4E-3 (Electrical conductivity) | 5.5E-6 (Electrical conductivity) | 6E7 (Electrical conductivity) | 2.5E-8 (Electrical resistivity) |

| Relative permittivity | 4.5 | 1 | 1 | 1 |

| Relative permeability | 1 | 80 | 1 | 1 |

| Parameter | Value |

|---|---|

| Coil power [kW] | 53 (Maximum operating power of the coil) |

| Frequency [kHz] | 3 |

| Operation Time [min] | 50 |

| C1 (m) | C2 (m) | C3 (m) | C4 (m) | C5 (m) |

|---|---|---|---|---|

| 0.01 | 0.02 | 0.03 | 0.04 | 0.05 |

| Parameter | Value |

|---|---|

| Power [kW] | 23 |

| Vacuum level of vacuum chamber [Torr] | 9.0*10-2 |

| Nozzle type | Direct injection type |

| Orifice diameter [mm] | 4 |

| Atomizing gas | Ar |

| Atomizing pressure [bar] | 25 |

Table 1.

Table 2.

Table 3.

TOP

KPMI

KPMI

ePub Link

ePub Link Cite this Article

Cite this Article