Search

- Page Path

- HOME > Search

- [Korean]

- Evaluation of Mechanical Properties of Pure Ni Coatings on a Type 316H Stainless Steel Substrate via High-Velocity Oxy-fuel and Directed Energy Deposition Processes

- Won Chan Lee, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

- J Powder Mater. 2025;32(4):309-314. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00185

- 834 View

- 9 Download

-

Abstract

Abstract

PDF

PDF - This study compares pure Ni coatings deposited on type 316H stainless steel using high-velocity oxy-fuel (HVOF) and directed energy deposition (DED) processes. Microstructural analysis showed that DED produced more uniform claddings with fewer pores, while HVOF resulted in incomplete melting and cracks. Elemental diffusion of Cr and Fe from the substrate into the cladding was evident in DED samples, especially at higher laser power, but minimal in HVOF due to low heat input. Vickers hardness testing revealed that DED claddings had higher hardness near the interface, which was attributed to solid solution strengthening and reduced porosity. Although HVOF better suppressed diffusion, it exhibited inferior mechanical properties due to internal defects. Overall, the DED process demonstrated superior coating quality and mechanical performance, suggesting its suitability for corrosion-resistant applications requiring both structural integrity and thermal stability, such as molten salt reactors.

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 792 View

- 51 Download

-

Abstract

Abstract

PDF

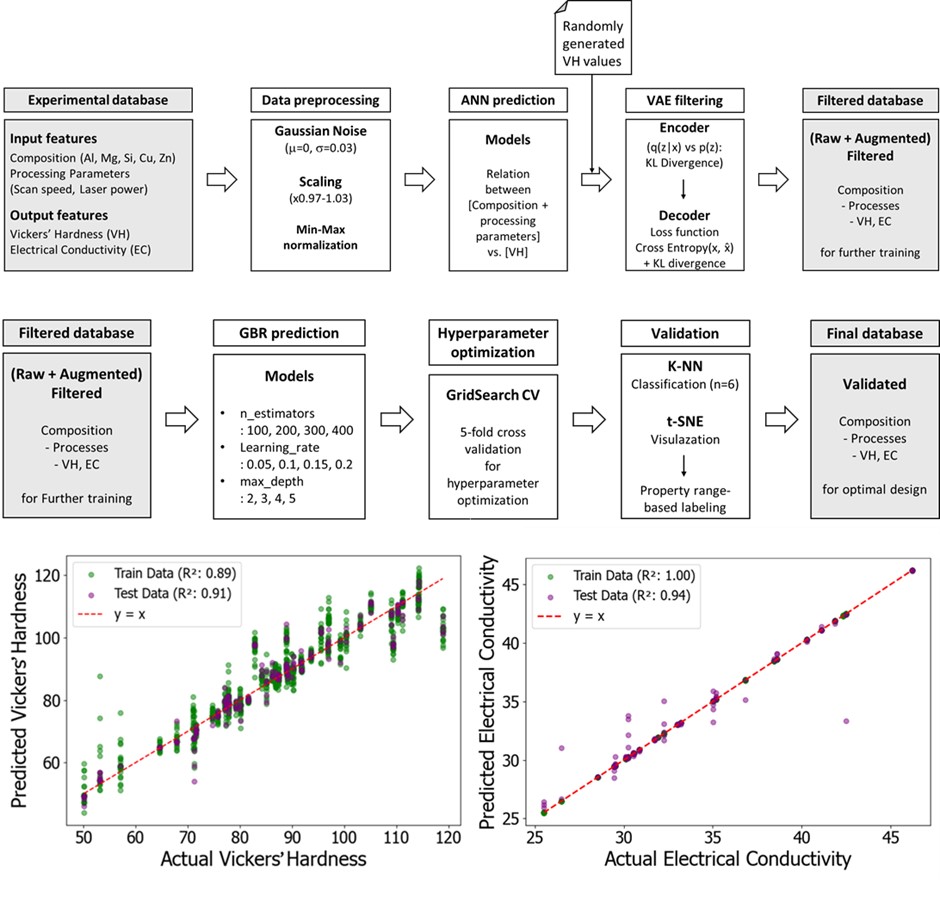

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [Korean]

- Joint Properties of Inconel 718 Additive Manufactured on Ti-6Al-4V by FGM method

- Chan Woong Park, Jin Woong Park, Ki Chae Jung, Se-Hwan Lee, Sung-Hoon Kim, Jeoung Han Kim

- J Korean Powder Metall Inst. 2021;28(5):417-422. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.417

- 589 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In the present work, Inconel 718 alloy is additively manufactured on the Ti-6Al-4V alloy, and a functionally graded material is built between Inconel 718 and Ti-6Al-4V alloys. The vanadium interlayer is applied to prevent the formation of detrimental intermetallic compounds between Ti-6Al-4V and Inconel 718 by direct joining. The additive manufacturing of Inconel 718 alloy is performed by changing the laser power and scan speed. The microstructures of the joint interface are characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and micro X-ray diffraction. Additive manufacturing is successfully performed by changing the energy input. The micro Vickers hardness of the additive manufactured Inconel 718 dramatically increased owing to the presence of the Cr-oxide phase, which is formed by the difference in energy input.

- [Korean]

- RBSC Prepared by Si Melt Infiltration into the Y2O3 Added Carbon Preform

- Min-Ho Jang, Kyeong-Sik Cho

- J Korean Powder Metall Inst. 2021;28(1):51-58. Published online February 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.1.51

- 1,449 View

- 15 Download

-

Abstract

Abstract

PDF

PDF The conversion of carbon preforms to dense SiC by liquid infiltration is a prospectively low-cost and reliable method of forming SiC-Si composites with complex shapes and high densities. Si powder was coated on top of a 2.0wt .% Y2O3-added carbon preform, and reaction bonded silicon carbide (RBSC) was prepared by infiltrating molten Si at 1,450°C for 1-8 h. Reactive sintering of the Y2O3-free carbon preform caused Si to be pushed to one side, thereby forming cracking defects. However, when prepared from the Y2O3-added carbon preform, a SiC-Si composite in which Si is homogeneously distributed in the SiC matrix without cracking can be produced. Using the Si + C → SiC reaction at 1,450°C, 3C and 6H SiC phases, crystalline Si, and Y2O3 were generated based on XRD analysis, without the appearance of graphite. The RBSC prepared from the Y2O3-added carbon preform was densified by increasing the density and decreasing the porosity as the holding time increased at 1,450°C. Dense RBSC, which was reaction sintered at 1,450°C for 4 h from the 2.0wt.% Y2O3-added carbon preform, had an apparent porosity of 0.11% and a relative density of 96.8%.

- [Korean]

- Mechanical Strength Values of Reaction-Bonded-Silicon-Carbide Tubes with Different Sample Size

- Seongwon Kim, Soyul Lee, Yoon-Suk Oh, Sung-Min Lee, Yoonsoo Han, Hyun-Ick Shin, Youngseok Kim

- J Korean Powder Metall Inst. 2017;24(6):450-456. Published online December 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.6.450

- 529 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Reaction-bonded silicon carbide (RBSC) is a SiC-based composite ceramic fabricated by the infiltration of molten silicon into a skeleton of SiC particles and carbon, in order to manufacture a ceramic body with full density. RBSC has been widely used and studied for many years in the SiC field, because of its relatively low processing temperature for fabrication, easy use in forming components with a near-net shape, and high density, compared with other sintering methods for SiC. A radiant tube is one of the most commonly employed ceramics components when using RBSC materials in industrial fields. In this study, the mechanical strengths of commercial RBSC tubes with different sizes are evaluated using 3-point flexural and C-ring tests. The size scaling law is applied to the obtained mechanical strength values for specimens with different sizes. The discrepancy between the flexural and C-ring strengths is also discussed.

- [English]

- Expansion of Multi-wall Carbon Nanotubes and its Lithium Storage Property

- Jung-Ho Ahn, Jeong-Seok Ahn

- J Korean Powder Metall Inst. 2017;24(4):275-278. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.275

- 817 View

- 2 Download

-

Abstract

Abstract

PDF

PDF In the present work, we apply a technique that has been used for the expansion of graphite to multiwall carbon nanotubes (MWCNT). The nanotubes are rapidly heated for a short duration, followed by immersion in acid solution, so that they undergo expansion. The diameter of the expanded CNTs is 5-10 times larger than that of the asreceived nanotubes. This results in considerable swelling of the CNTs and opening of the tube tips, which may facilitate the accessibility of lithium ions into the inner holes and the interstices between the nanotube walls. The Li-ion storage capacity of the expanded nanotubes is measured by using the material as an anode in Li-ion cells. The result show that the discharge capacity of the expanded nanotubes in the first cycle is as high as 2,160 mAh/g, which is about 28% higher than that of the un-treated MWCNT anode. However, the charge/discharge capacity quickly drops in subsequent cycles and finally reaches equilibrium values of ~370 mAh/g. This is possibly due to the destruction of the lattice structures by repeated intercalation of Li ions.

- [English]

- Research Trend of Additive Manufacturing Technology

- Hanshin Choi, Jong Min Byun, Wonsik Lee, Su-Ryong Bang, Young Do Kim

- J Korean Powder Metall Inst. 2016;23(2):149-169. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.149

- 3,129 View

- 8 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF Additive manufacturing (AM) is defined as the manufacture of three-dimensional tangible products by additively consolidating two-dimensional patterns layer by layer. In this review, we introduce four fundamental conceptual pillars that support AM technology: the bottom-up manufacturing factor, computer-aided manufacturing factor, distributed manufacturing factor, and eliminated manufacturing factor. All the conceptual factors work together; however, business strategy and technology optimization will vary according to the main factor that we emphasize. In parallel to the manufacturing paradigm shift toward mass personalization, manufacturing industrial ecology evolves to achieve competitiveness in economics of scope. AM technology is indeed a potent candidate manufacturing technology for satisfying volatile and customized markets. From the viewpoint of the innovation technology adoption cycle, various pros and cons of AM technology themselves prove that it is an innovative technology, in particular a disruptive innovation in manufacturing technology, as powder technology was when ingot metallurgy was dominant. Chasms related to the AM technology adoption cycle and efforts to cross the chasms are considered.

-

Citations

Citations to this article as recorded by- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

Kwangtae Son, Seung-Min Jeon, Brian K. Paul, Young-Sang Na, Kijoon Lee, Young-Kyun Kim

Journal of Materials Science & Technology.2025;[Epub] CrossRef - SiC-Si composite part fabrication via SiC powder binder jetting additive manufacturing and molten-Si infiltration

Ji-Won Oh, Jinsu Park, Sahn Nahm, Hanshin Choi

International Journal of Refractory Metals and Hard Materials.2021; 101: 105686. CrossRef - Recent Trends and Application Status of the Metal Matrix Composites (MMCs)

Hyo-Seop Kim

Journal of Korean Powder Metallurgy Institute.2020; 27(2): 164. CrossRef - Metal Additive Manufacturing Cycle in Aerospace Industry: A Comprehensive Review

B. Barroqueiro, A. Andrade-Campos, R. A. F. Valente, V. Neto

Journal of Manufacturing and Materials Processing.2019; 3(3): 52. CrossRef - Technology Trend of the additive Manufacturing (AM)

Ji-Won Oh, Hyunwoong Na, Hanshin Choi

Journal of Korean Powder Metallurgy Institute.2017; 24(6): 494. CrossRef

- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

- [Korean]

- Effect of the SiC Size on the Thermal and Mechanical Properties of Reaction-bonded Silicon Carbide Ceramics

- Chang-Sup Kwon, Yoon-Suk Oh, Sung-Min Lee, Yoonsoo Han, Hyun-Ick Shin, Youngseok Kim, Seongwon Kim

- J Korean Powder Metall Inst. 2014;21(6):467-472. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.467

- 1,485 View

- 13 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF RBSC (reaction-bonded silicon carbide) represents a family of composite ceramics processed by infiltrating with molten silicon into a skeleton of SiC particles and carbon in order to fabricate a fully dense body of silicon carbide. RBSC has been commercially used and widely studied for many years, because of its advantages, such as relatively low temperature for fabrication and easier to form components with near-net-shape and high relative density, compared with other sintering methods. In this study, RBSC was fabricated with different size of SiC in the raw material. Microstructure, thermal and mechanical properties were characterized with the reaction-sintered samples in order to examine the effect of SiC size on the thermal and mechanical properties of RBSC ceramics. Especially, phase volume fraction of each component phase, such as Si, SiC, and C, was evaluated by using an image analyzer. The relationship between microstructures and physical properties was also discussed.

-

Citations

Citations to this article as recorded by- Structural and Mechanical Properties of SiC-Rich By-Products of the Metal Grade Si Process

Thomas Hafner, Jonas Hafner, Frank Kimm, Vira Bovda, Oleksandr Bovda, Oleksandr Kuprin, Anatoliy Pikalov, Kostiantyn Lentsov, Pavlo Schikhaylo, Yriy Onyschuk, Andriy Tarasuk, Viktoriya Podhurska, Bogdan Vasyliv, Oleksandr Shcheretsky, Ihor Vorona, Roman Y

Materials Science Forum.2024; 1113: 87. CrossRef - Effect of Y2O3 Additive Amount on Densification of Reaction Bonded Silicon Carbides Prepared by Si Melt Infiltration into All Carbon Preform

Kyeong-Sik Cho, Min-Ho Jang

Korean Journal of Materials Research.2021; 31(5): 301. CrossRef - Mechanical Strength Values of Reaction-Bonded-Silicon-Carbide Tubes with Different Sample Size

Seongwon Kim, Soyul Lee, Yoon-Suk Oh, Sung-Min Lee, Yoonsoo Han, Hyun-Ick Shin, Youngseok Kim

Journal of Korean Powder Metallurgy Institute.2017; 24(6): 450. CrossRef

- Structural and Mechanical Properties of SiC-Rich By-Products of the Metal Grade Si Process

TOP

KPMI

KPMI

First

First Prev

Prev