Search

- Page Path

- HOME > Search

Critical Reviews

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,559 View

- 119 Download

- 4 Citations

-

Abstract

Abstract

PDF

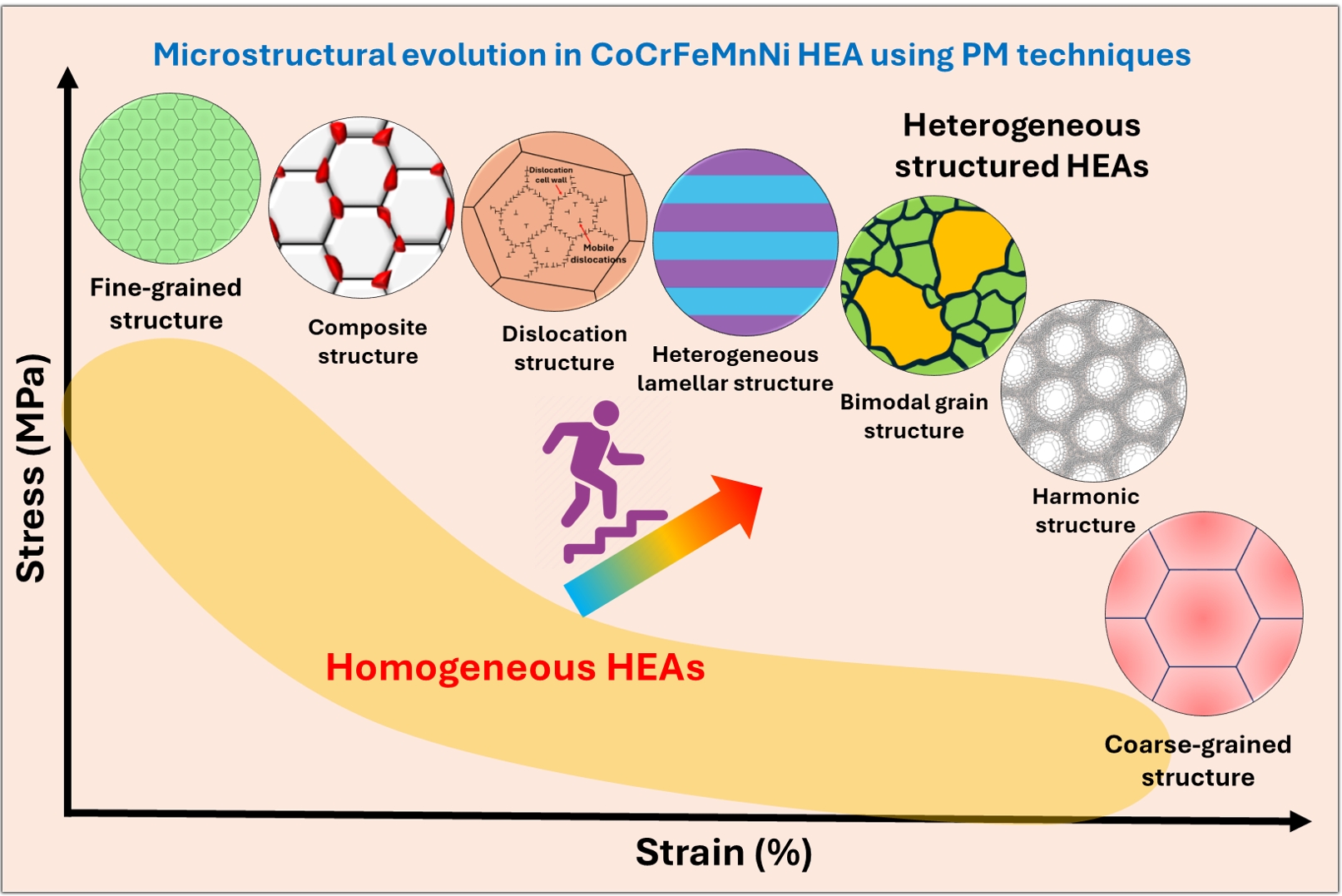

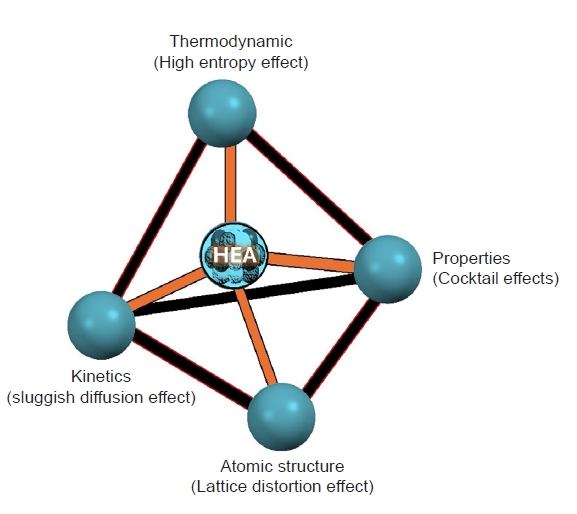

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 5,069 View

- 169 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

Leonardo Baylón García, José Manuel Mendoza Duarte, Ivanovich Estrada Guel, Audel Santos Beltrán, Hansel Manuel Medrano Prieto, Gustavo Rodríguez Cabriales, Enrique Rocha Rangel, José Luis Hernández Rivera, Roberto Martínez Sánchez, Alfredo Martínez Garcí

Coatings.2026; 16(3): 275. CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Latest Advancements and Mechanistic Insights into High-Entropy Alloys: Design, Properties and Applications

Anthoula Poulia, Alexander E. Karantzalis

Materials.2025; 18(24): 5616. CrossRef

- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

TOP

KPMI

KPMI

First

First Prev

Prev