Search

- Page Path

- HOME > Search

Research Articles

- [English]

- Enhanced Compressive Strength of Fired Iron Ore Pellets: Effects of Blending Fine and Coarse Particle Concentrates

- Ngo Quoc Dung, Tran Xuan Hai, Nguyen Minh Thuyet, Nguyen Quang Tung, Arvind Barsiwal, Nguyen Hoang Viet

- J Powder Mater. 2025;32(4):315-329. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00129

- 1,500 View

- 68 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of oxidative firing parameters and raw material characteristics on the pelletization of Australian and Minh Son (Vietnam) iron ore concentrates. The influence of firing temperature (1050°C–1150°C) and holding time (15–120 min) on pellet compressive strength was examined, focusing on microstructural changes during consolidation. Green pellets were prepared using controlled particle size distributions and bentonite as a binder. Scanning electron microscopy and energy-dispersive X-ray spectroscopy analyses revealed that grain boundary diffusion, liquid phase formation, and densification significantly improved mechanical strength. X-ray diffraction confirmed the complete oxidation of magnetite to hematite at elevated temperatures, a critical transformation for metallurgical performance. Optimal firing conditions for both single and blended ore compositions yielded compressive strengths above 250 kgf/pellet, satisfying the requirements for blast furnace applications. These results provide valuable guidance for improving pellet production, promoting the efficient utilization of diverse ore types, and enhancing the overall performance of ironmaking operations.

- [English]

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- 1,487 View

- 63 Download

- 2 Citations

-

Abstract

Abstract

PDF

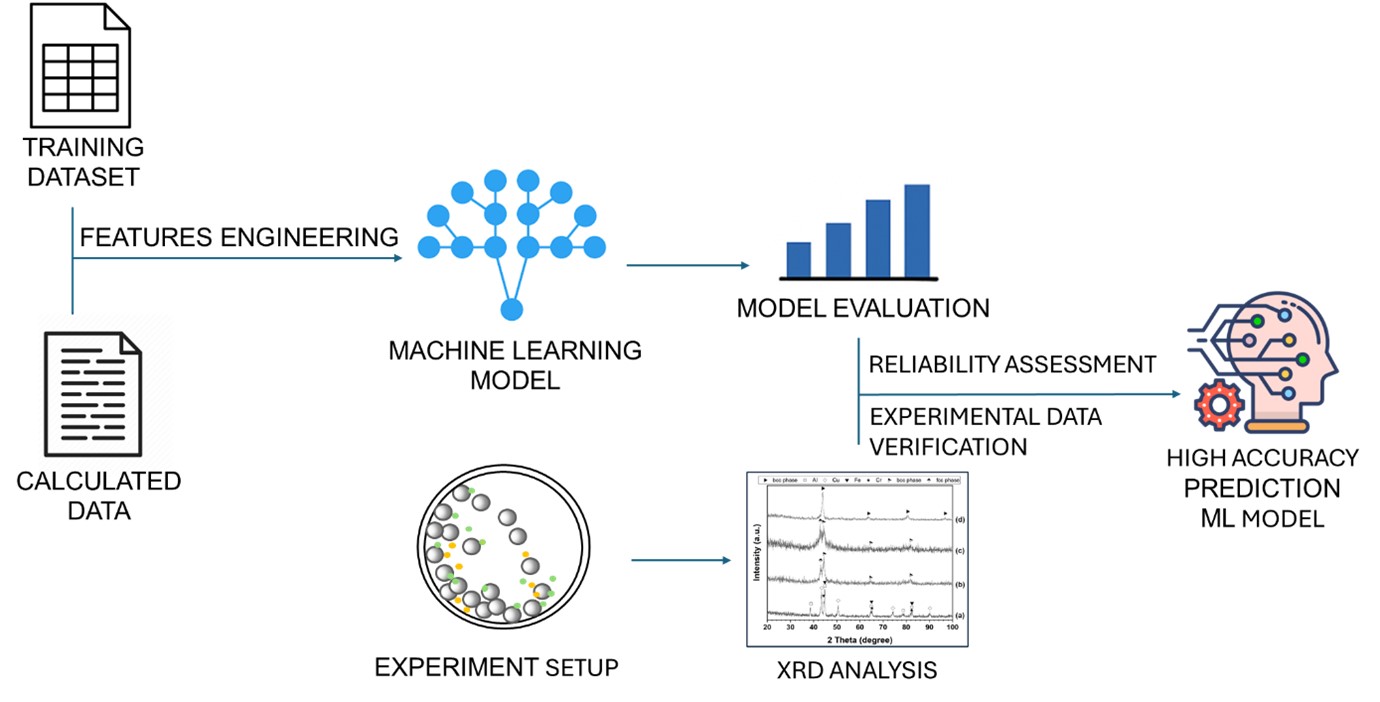

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025; 56(5): 5948. CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; 8: 100038. CrossRef

- Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

- [English]

- The Formation and Crystallization of Amorphous Ti50Cu50Ni20Al10 Powder Prepared by High-Energy Ball Milling

- Nguyen Hoang Viet, Jin-Chun Kim, Ji-Soon Kim, Young-Soon Kwon

- J Korean Powder Metall Inst. 2009;16(1):9-15.

- DOI: https://doi.org/10.4150/KPMI.2009.16.1.009

- 624 View

- 0 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Amorphization and crystallization behaviors of Ti_50Cu_50Ni_20Al_10 powders during high-energy ball milling and subsequent heat treatment were studied. Full amorphization obtained after milling for 30 h was confirmed by X-ray diffraction and transmission electron microscope. The morphology of powders prepared using different milling times was observed by field-emission scanning electron microscope. The powders developed a fine, layered, homogeneous structure with prolonged milling. The crystallization behavior showed that the glass transition, T_g, onset crystallization, T_x, and super cooled liquid range DeltaT=T_x-T_g were 691,771 and 80 K, respectively. The isothermal transformation kinetics was analyzed by the John-Mehn-Avrami equation. The Avrami exponent was close to 2.5, which corresponds to the transformation process with a diffusion-controlled type at nearly constant nucleation rate. The activation energy of crystallization for the alloy in the isothermal annealing process calculated using an Arrhenius plot was 345 kJ/mol.

-

Citations

Citations to this article as recorded by- Mechanical Properties of Bulk Amorphous Ti50Cu20Ni20Al10Fabricated by High-energy Ball Milling and Spark-plasma Sintering

H.V. Nguyen, J.C. Kim, J.S. Kim, Y.J. Kwon, Y.S. Kwon

Journal of Korean Powder Metallurgy Institute.2009; 16(5): 358. CrossRef

- Mechanical Properties of Bulk Amorphous Ti50Cu20Ni20Al10Fabricated by High-energy Ball Milling and Spark-plasma Sintering

TOP

KPMI

KPMI

First

First Prev

Prev