Search

- Page Path

- HOME > Search

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 792 View

- 51 Download

-

Abstract

Abstract

PDF

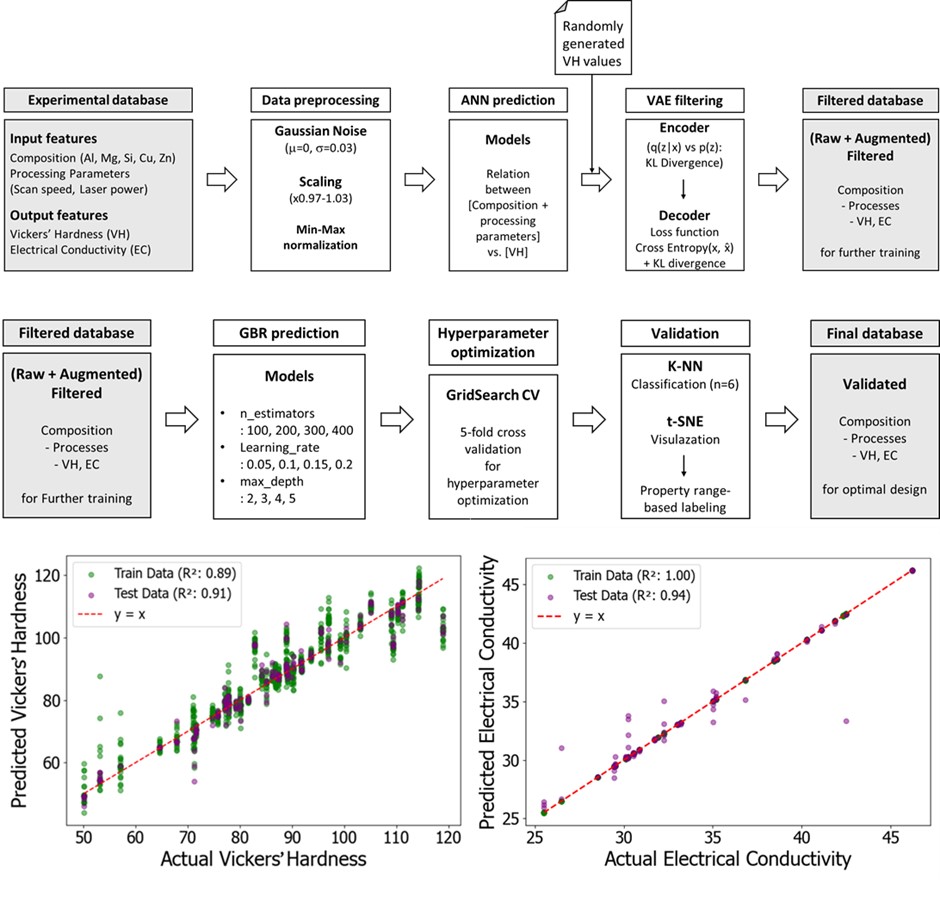

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [English]

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- 2,469 View

- 82 Download

- 3 Citations

-

Abstract

Abstract

PDF

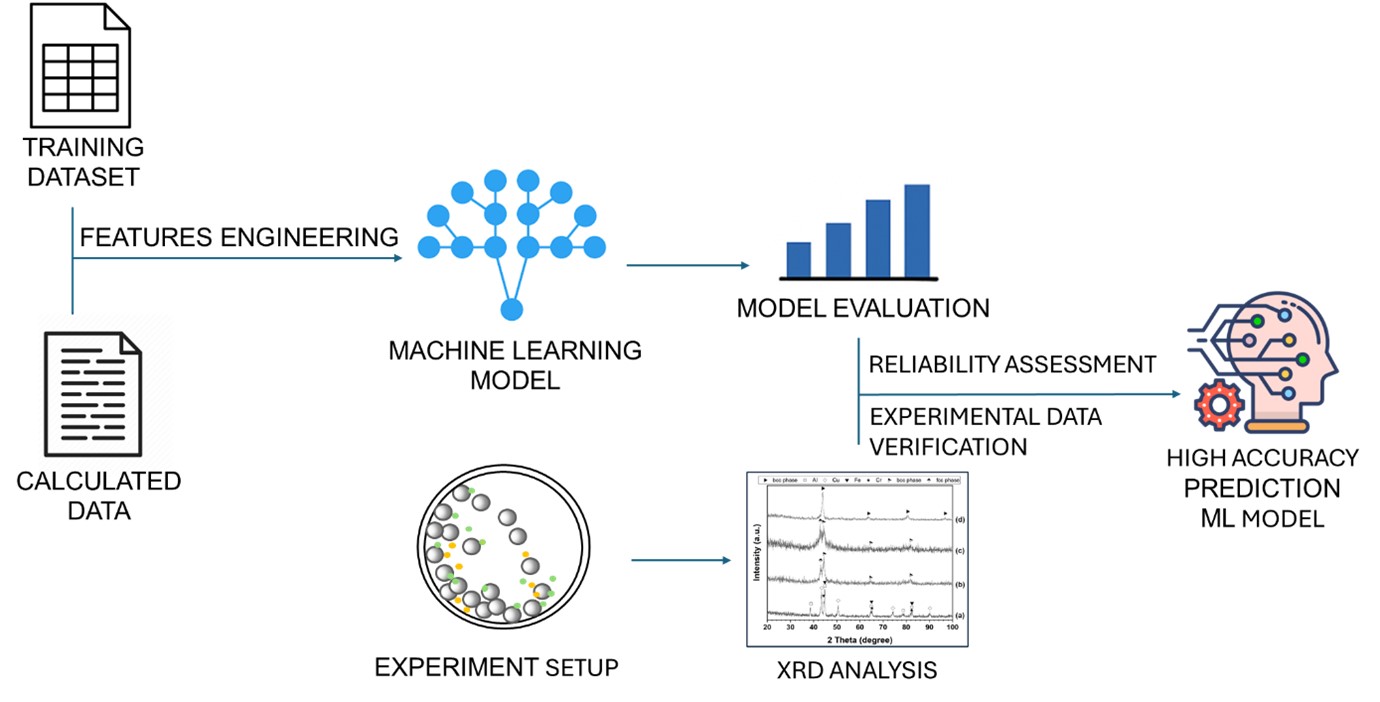

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025; 56(5): 5948. CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; 8: 100038. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

- Porosity Prediction of the Coating Layer Based on Process Conditions of HVOF Thermal Spray Coating

- Junhyub Jeon, Namhyuk Seo, Jong Jae Lee, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(6):478-482. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.478

- 446 View

- 2 Download

-

Abstract

Abstract

PDF

PDF The effect of the process conditions of high-velocity oxygen fuel (HVOF) thermal spray coating on the porosity of the coating layer is investigated. HVOF coating layers are formed by depositing amorphous FeMoCrBC powder. Oxygen pressure varies from 126 to 146 psi and kerosene pressure from 110 to 130 psi. The Microstructural analysis confirms its porosity. Data analysis is performed using experimental data. The oxygen pressure-kerosene pressure ratio is found to be a key contributor to the porosity. An empirical model is proposed using linear regression analysis. The proposed model is then validated using additional test data. We confirm that the oxygen pressure-kerosene pressure ratio exponentially increases porosity. We present a porosity prediction model relationship for the oxygen pressure-kerosene pressure ratio.

- [English]

- Modeling the Density and Hardness of AA2024-SiC Nanocomposites

- A-Hyun Jeon, Hong In Kim, Hyokyung Sung, N. S. Reddy

- J Korean Powder Metall Inst. 2019;26(4):275-281. Published online August 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.4.275

- 1,017 View

- 3 Download

-

Abstract

Abstract

PDF

PDF An artificial neural network (ANN) model is developed for the analysis and simulation of correlation between flake powder metallurgy parameters and properties of AA2024-SiC nanocomposites. The input parameters of the model are AA 2024 matrix size, ball milling time, and weight percentage of SiC nanoparticles and the output parameters are density and hardness. The model can predict the density and hardness of the unseen test data with a correlation of 0.986 beyond the experimental data. A user interface is designed to predict properties at new instances. We have used the model to simulate the individual as well as the combined influence of parameters on the properties. Moreover, we have analyzed the calculated results from the powder metallurgical point of view. The developed model can be used as a guide for further composite development.

TOP

KPMI

KPMI

First

First Prev

Prev