Search

- Page Path

- HOME > Search

Research Articles

- [Korean]

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

- YongKwan Lee, Hyun-chul Kim, Myungsuk Kim, Soong Ju Oh, Kyoungtae Park, JaeJin Sim

- J Powder Mater. 2025;32(4):330-343. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00136

- 1,105 View

- 15 Download

-

Abstract

Abstract

PDF

PDF - Co-Cr alloys are widely used in cutting tools and turbine components due to their high strength and resistance against wear and corrosion. However, scrap generated during hardfacing is often discarded due to impurities and oxidation, and research on its recycling remains limited. This study aimed to optimize the recycling process of Stellite 6 scrap to reduce waste and minimize costs while maintaining material quality. Melting, casting, and powdering processes were designed using HSC Chemistry, FactSage, and COMSOL Multiphysics, with optimization of key parameters such as the crucible material and temperature control. The recycled alloy and powder were analyzed using X-ray fluorescence analysis, inductively coupled plasma optical emission spectroscopy, and X-ray diffractometry, showing mechanical and chemical properties comparable to commercial Stellite 6. The Co and Cr contents were maintained, with a slight increase in Fe. These findings demonstrate the potential for producing high-quality recycled Stellite 6 materials, contributing to the sustainable utilization of metal resources in high-performance applications.

- [Korean]

- Effect of Hot Isostatic Pressing on the Stellite 6 Alloy prepared by Directed Energy Deposition

- Joowon Suh, Jae Hyeon Koh, Young-Bum Chun, Young Do Kim, Jinsung Jang, Suk Hoon Kang, Heung Nam Han

- J Powder Mater. 2024;31(2):152-162. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00066

- 1,762 View

- 39 Download

- 1 Citations

-

Abstract

Abstract

PDF

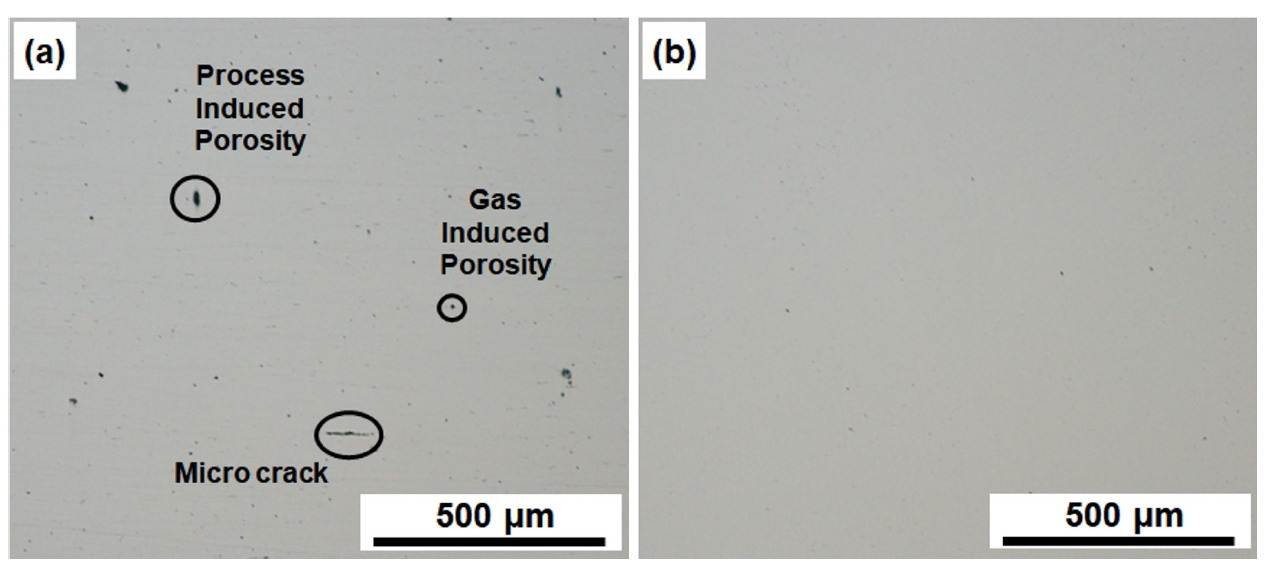

PDF - The directed energy deposited (DED) alloys show higher hardness values than the welded alloys due to the finer microstructure following the high cooling rate. However, defects such as microcracks, pores, and the residual stress are remained within the DED alloy. These defects deteriorate the wear behavior so post-processing such as heat treatment and hot isostatic pressing (HIP) are applied to DED alloys to reduce the defects. HIP was chosen in this study because the high pressure and temperature uniformly reduced the defects. The HIP is processed at 1150oC under 100 MPa for 4 hours. After HIP, microcracks are disappeared and porosity is reduced by 86.9%. Carbides are spherodized due to the interdiffusion of Cr and C between the dendrite and interdendrite region. After HIP, the nanohardness (GPa) of carbides increased from 11.1 to 12, and the Co matrix decreased from 8.8 to 7.9. Vickers hardness (HV) decreased by 18.9 % after HIP. The dislocation density (10-2/m2) decreased from 7.34 to 0.34 and the residual stress (MPa) changed from tensile 79 to a compressive -246 by HIP. This study indicates that HIP is effective in reducing defects, and the HIP DED Stellite 6 exhibits a higher HV than welded Stellite 6.

-

Citations

Citations to this article as recorded by- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

YongKwan Lee, Hyun-chul Kim, Myungsuk Kim, Soong Ju Oh, Kyoungtae Park, JaeJin Sim

Journal of Powder Materials.2025; 32(4): 330. CrossRef

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

TOP

KPMI

KPMI

First

First Prev

Prev