Articles

- Page Path

- HOME > J Powder Mater > Volume 31(5); 2024 > Article

-

Critical Review

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra1, Gargi Roy1, An Seong Min1, Hyunseok Lee2,*, Jeoung Han Kim2,*

-

Journal of Powder Materials 2024;31(5):365-373.

DOI: https://doi.org/10.4150/jpm.2024.00213

Published online: October 31, 2024

1Department of Materials Science & Engineering, Hanbat National University, Daejeon, 34158, Korea

2Titanium Research Group, Research Institute of Industrial Science and Technology, Nam-gu, Pohang, Republic of Korea

-

*Corresponding author: hslee0@rist.re.kr

*Corresponding author: jh.kim@hanbat.ac.kr

• Received: July 28, 2024 • Revised: September 14, 2024 • Accepted: September 14, 2024

© The Korean Powder Metallurgy & Materials Institute

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 2,860 Views

- 67 Download

- 2 Crossref

Figure & Data

References

Citations

Citations to this article as recorded by

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef

ePub Link

ePub Link-

Cite this Article

Cite this Article

- Cite this Article

-

- Close

- Download Citation

- Close

- Figure

- Related articles

-

- Microstructure and Mechanical Properties of AA3003 Tube for Heat Exchanger Processed by Floating Plug Drawing

- Effect of Hatch Spacing on the Microstructure and Mechanical Properties of SA508 Gr.3 Steel Fabricated by Laser Powder Bed Fusion

- Microstructure and Mechanical Properties of Laser Powder Bed Fusion 3D-Printed Cu-10Sn Alloy

- Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

- Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

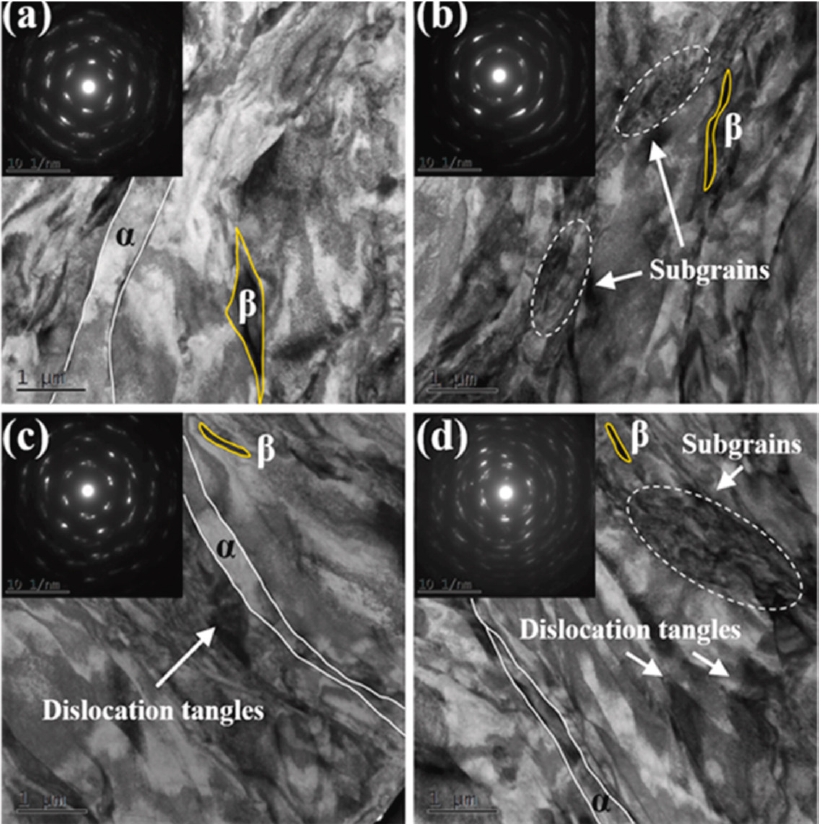

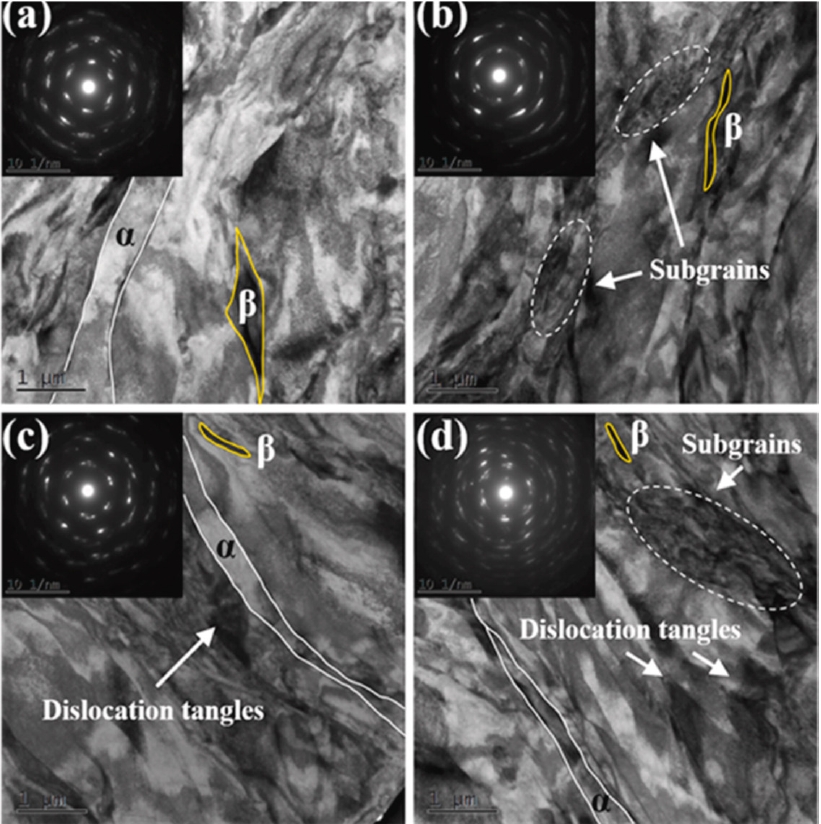

Fig. 1. Fig. 1. Bright field transmission electron microscopy images of the specimens rolled at (a) 293 K-50%, (b) 173 K-50%, (c) 123 K-50%, and (d) 83 K-50%. Top left images show the selected area electron diffraction patterns of the corresponding specimens. This figure is reproduced from Yu et al. [39].

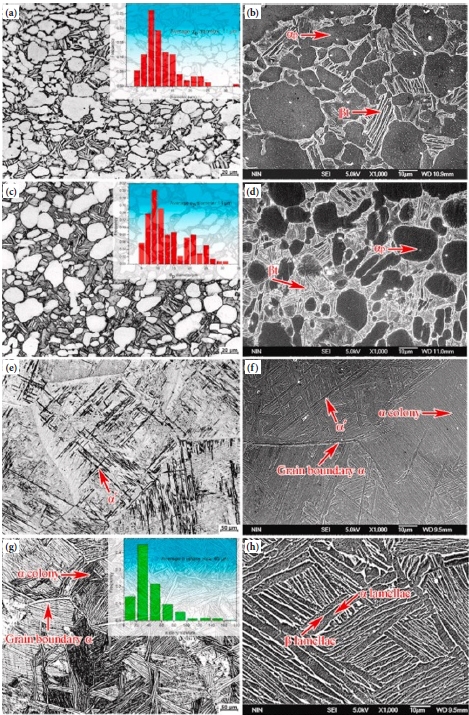

Fig. 2. Microstructures of the Ti–6Al–4V alloy: (a, b) EM, (c, d) BM, (e, f) LM1, (g, h) LM2. This figure is reproduced from Ref. [44].

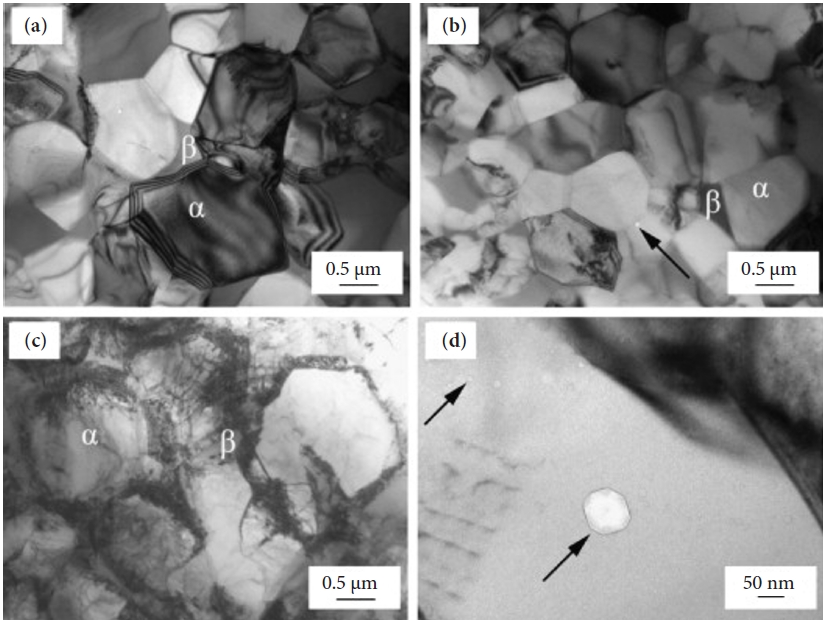

Fig. 3. Transmission electron microscopy images show matrix microstructures of Ti-6Al-4 V sintered samples with different milling times. (a) 10 h, (b) 40 h, and (c) 50 h. (d) demonstrates nanostructured oxide particles distributed in a grain of the sintered sample with a milling time of 40 h. [50].

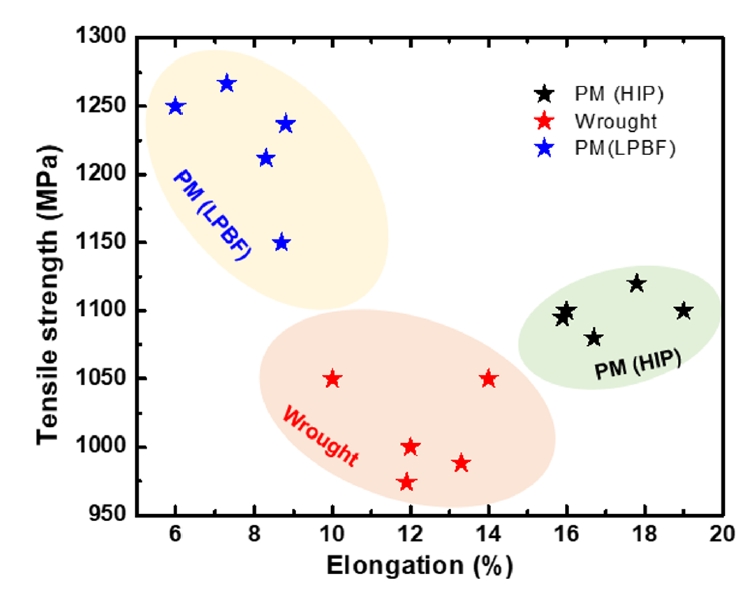

Fig. 4. Comparison of tensile strength and elongation of Ti-6Al-4V alloys fabricated trough different processes.

Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

| Processing route | Heat treatment | Grain size (μm) | Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Reference |

|---|---|---|---|---|---|---|

| Wrought (forging) | Mill annealing and recrystallization annealing | 23-29 | 950 | 1050 | 14 | Pratap et al. [42] |

| Wrought (rolling) | Cryorolling at low temperatures | 0.3-0.5 | 930 | 1000 | 12 | Yu et al., [56] |

| PM (HIP) | Solution treatment at 950°C, aging at 460°C | 18-26 | 1030 | 1100 | 16 | Liu et al., [57] |

| PM (LPBF) | As-built | 5-10 | 1042.2 | 1150 | 8.7 | Baghi et al., [49] |

| PM (LPBF + HIP) | HIP post-processing | 125 | 1030 | 1080 | 16.7 | Varela et al., [54] |

| PM (EBM) | As-built | 0.5-1.0 | 950 | 1050 | 10 | Rashid et al., [58] |

| PM (SLM) | Solution treatment at 950°C, aging at 460°C | 7-8 | 1000 | 1100 | 11 | Tang et al., [46] |

Table 1. Comparison of yield strength, tensile strength and elongation of Ti-6Al-4V alloys fabricated through different processes

Table 1.

TOP

KPMI

KPMI