Most cited

- Page Path

- HOME > Browse Articles > Most cited

- [Korean]

- Planetary Ball Mill Process in Aspect of Milling Energy

- Huynh Xuan Khoa, Sunwoo Bae, Sangwon Bae, Byeong-woo Kim, Ji Soon Kim

- J Korean Powder Metall Inst. 2014;21(2):155-164. Published online April 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.2.155

- 6,424 View

- 370 Download

- 39 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Particle interactions during dry powder mixing and their effect on solvent-free manufactured electrode properties

Zhongjia Gao, Jinzhao Fu, Chinmoy Podder, Xiangtao Gong, Yan Wang, Heng Pan

Journal of Energy Storage.2024; 83: 110605. CrossRef - Towards a More Sustainable Leaching Process for Li-Ion Battery Cathode Material Recycling: Mechanochemical Leaching of LiCoO2 Using Citric Acid

Joshua Vauloup, Cécile Bouilhac, Nicolas Coppey, Patrick Lacroix-Desmazes, Lorenzo Stievano, Laure Monconduit, Moulay Tahar Sougrati

ACS Sustainable Resource Management.2024; 1(9): 2032. CrossRef - Conduction mechanism of a moisture diffusion energy harvesting device prepared with mesopore-rich activated carbon

Sa-Myeong Gim, Sadaf Mearaj, Hyeonoh Hwang, Xuanjun Jin, Joon Weon Choi

Materials Today Communications.2024; 40: 109743. CrossRef - Toksik organik kirleticilerin mekanokimyasal parçalanması

Volkan Pelitli

Balıkesir Üniversitesi Fen Bilimleri Enstitüsü Dergisi.2024; 26(2): 635. CrossRef - Navigating Ball Mill Specifications for Theory‐to‐Practice Reproducibility in Mechanochemistry

Orein F. Jafter, Sol Lee, Jongseong Park, Clément Cabanetos, Dominik Lungerich

Angewandte Chemie International Edition.2024;[Epub] CrossRef - Advancing sustainable practices in Li-ion battery cathode material recycling: mechanochemical optimisation for magnetic cobalt recovery

Joshua Vauloup, Cécile Bouilhac, Nicolas Coppey, Patrick Lacroix-Desmazes, Bernard Fraisse, Lorenzo Stievano, Laure Monconduit, Moulay Tahar Sougrati

RSC Mechanochemistry.2024; 1(4): 393. CrossRef - Ultrafine Sm2Fe17N3 hard magnetic particles synthesized by mechanochemical process

Zhi Yang, Yuanyuan Chen, Haochuan Yang, Xiaofeng Nie, Junhua Xi, Jie Zhang, Weiqiang Liu, Ming Yue

Applied Materials Today.2024; 41: 102453. CrossRef - Navigating Ball Mill Specifications for Theory‐to‐Practice Reproducibility in Mechanochemistry

Orein F. Jafter, Sol Lee, Jongseong Park, Clément Cabanetos, Dominik Lungerich

Angewandte Chemie.2024;[Epub] CrossRef - Optimizing reuse of Vanadis® 8 tool steel powders through multi-objective Lichtenberg algorithm: A powder metallurgy approach

Elioenai Levi Barbedo, João Luiz Junho Pereira, Lucas Antônio de Oliveira, Matheus David Guimarães Barbedo, Matheus Brendon Francisco, Guilherme Ferreira Gomes, Gilbert Silva

Advanced Powder Technology.2024; 35(4): 104416. CrossRef - Solution-Free Growth of CsPbBr3 Perovskite Films Using a Fast and Scalable Close Space Sublimation Method

Jakob Ihrenberger, Frédéric Roux, Ferdinand Lédée, Fabrice Emieux, Christelle Anglade, Thibault Lemercier, Géraldine Lorin, Eric Gros-Daillon, Louis Grenet

Crystal Growth & Design.2024; 24(13): 5542. CrossRef - Powder ball milling: An energy balance approach to particle size reduction

Stefano Martelli, Paolo Emilio Di Nunzio

Journal of Materials Research.2024;[Epub] CrossRef - Recent advances in the application of dolomite in membrane separation and beyond: A review on an abundant and versatile mineral

Muhammed Sahal Siddique, N Awanis Hashim, Mohd Usman Mohd Junaidi, Aubaid Ullah, Rozita Yusoff, Mohamad Fairus Rabuni

Materials Today Sustainability.2024; 28: 100951. CrossRef - Wet mechanochemical surface modification of calcite employing an integration of conventional design and analytical hierarchy process

Metin Uçurum, Akın Özdemir

Powder Technology.2024; 443: 119970. CrossRef - Bi-functional hydrogen tungsten bronze/carbon composite catalysts towards biomass conversion and solar water purification

Akitaka Yabuki, Kunihiko Kato, Yunzi Xin, Yuping Xu, Takashi Shirai

Materialia.2024; 38: 102249. CrossRef - Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

Hansung Lee, Minsu Kim, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(4): 332. CrossRef - Influence of Mixing Process on the Performance of Electrodes Made by a Dry Coating Method

Ming Wang, Kubra Uzun, Bradley R. Frieberg, Jiazhi Hu, Anita Li, Xiaosong Huang, Yang-Tse Cheng

Journal of The Electrochemical Society.2023; 170(1): 010541. CrossRef - Influence of ball materials on the surface activation behavior of coal ash particles during a mechanochemical process

Takumi Sangu, Yunzi Xin, Takashi Hitomi, Kunihiko Kato, Takashi Shirai

Ceramics International.2023; 49(21): 34327. CrossRef - Mechanosynthesizing a dual cation orthophosphate using planetary ball mill; Potassium struvite production employing different primary components

Alimohammad Dehghan Manshady, Gholamreza Rakhshandehroo, Nasser Talebbeydokhti

Advanced Powder Technology.2022; 33(10): 103751. CrossRef - Comparison study of physicochemical and biopharmaceutics properties of hydrophobic drugs ground by two dry milling processes

M. Dandignac, S. P. Lacerda, A. Chamayou, L. Galet

Pharmaceutical Development and Technology.2022; 27(7): 816. CrossRef - Effects of two-step high-energy ball milling process and hot isostatic pressing on the mechanical properties of PM magnesium

Jesus María Rios, Alex Humberto Restrepo, Alejandro Alberto Zuleta, Francisco Javier Bolívar, Juan Guillermo Castaño, Esteban Correa, Félix Echeverria

The International Journal of Advanced Manufacturing Technology.2022; 121(1-2): 187. CrossRef - A chemical milling process to produce water-based inkjet printing ink from waste tire carbon blacks

I-Feng Wu, Ying-Chih Liao

Waste Management.2021; 122: 64. CrossRef - Microstructural Design of Ba0.5La0.5Co0.5Fe0.5O3 Perovskite Ceramics

Daria Gierszewska, Iga Szpunar, Francis Oseko, Joanna Pośpiech, Małgorzata Nadolska, Martyna Pieragowska, Karolina Reniecka, Kinga Waniek, Karol Leszczyński, Aleksandra Mielewczyk-Gryń, Maria Gazda, Sebastian Wachowski

Materials.2021; 14(16): 4656. CrossRef - Mechanical high-energy treatment of TiNi powder and phase changes after electrochemical hydrogenation

E.V. Abdulmenova, S.N. Kulkov

International Journal of Hydrogen Energy.2021; 46(1): 823. CrossRef - Rejuvenation of granulated blast furnace slag (GBS) glass by ball milling

N. Romero Sarcos, D. Hart, H. Bornhöft, A. Ehrenberg, J. Deubener

Journal of Non-Crystalline Solids.2021; 556: 120557. CrossRef - Key Factors During the Milling Stage of the Seed‐assisted and Solvent‐free Synthesis of MFI and Catalytic Behavior in the Alkylation of Phenol with Tert‐butyl Alcohol

Julieth Tatiana García‐Sánchez, Iván Darío Mora‐Vergara, Daniel Ricardo Molina‐Velasco, José Antonio Henao‐Martínez, Víctor Gabriel Baldovino‐Medrano

ChemCatChem.2021; 13(16): 3713. CrossRef - Nanocellulose acetate membranes: Preparation and application

Ahmed S. Al-Rawi, Ismail K. Ibrahim Al-Khateeb, Tahseen A. Zaidan

Environmental Nanotechnology, Monitoring & Management.2021; 16: 100529. CrossRef - Mechanochemical tuning of molecular weight distribution of styrene homopolymers as postpolymerization modification in solvent‐free solid‐state

Milton Jimenez‐Francisco, Jose Gonzalo Carrillo, Luis Alfonso Garcia‐Cerda

Journal of Applied Polymer Science.2021;[Epub] CrossRef - From Machining Chips to Raw Material for Powder Metallurgy—A Review

Catarina Duarte Batista, Adriana André Martins das Neves de Pinho Fernandes, Maria Teresa Freire Vieira, Omid Emadinia

Materials.2021; 14(18): 5432. CrossRef - Optimization of Milling Procedures for Synthesizing Nano-CaCO3 from Achatina fulica Shell through Mechanochemical Techniques

O. J. Gbadeyan, S. Adali, G. Bright, B. Sithole, S. Onwubu

Journal of Nanomaterials.2020; 2020: 1. CrossRef - High yield solvent extraction of hydrothermal and ball-milling treated lignin prior to enzymatic hydrolysis for co-valorization of lignin and cellulose in Miscanthus sacchariflorus

Soo-Kyeong Jang, Jae Hoon Lee, Chan-Duck Jung, Ju-Hyun Yu, Joon Weon Choi, In-Gyu Choi, Hoyong Kim

Fuel.2020; 269: 117428. CrossRef - Obtaining of tungsten nanopowders by high energy ball milling

A V Ozolin, E G Sokolov, D A Golius

IOP Conference Series: Materials Science and Engineering.2020; 862(2): 022057. CrossRef - Improvement Parameters of Hydrogen Generation from Water under Stainless-Steel-Mediated Ball Milling Conditions

Miki Itoh, Yoshinari Sawama, Miki Niikawa, Kazuho Ban, Takahiro Kawajiri, Hironao Sajiki

Bulletin of the Chemical Society of Japan.2020; 93(11): 1366. CrossRef - Overcoming the Solubility Barrier of Ibuprofen by the Rational Process Design of a Nanocrystal Formulation

Andreas Ouranidis, Nikos Gkampelis, Elisavet Vardaka, Anna Karagianni, Dimitrios Tsiptsios, Ioannis Nikolakakis, Kyriakos Kachrimanis

Pharmaceutics.2020; 12(10): 969. CrossRef - A novel approach to synthesize nitrogen-doped graphene in aspects of milling energy

Rachit Ranjan, Ravi Shankar Rai, Vivek Bajpai

Diamond and Related Materials.2020; 110: 108116. CrossRef - The influence of the rotation frequency of a planetary ball mill on the limiting value of the specific surface area of the WC and Co nanopowders

Maksim Dvornik, Elena Mikhailenko

Advanced Powder Technology.2020; 31(9): 3937. CrossRef - Kalsiyum oksit varlığında teknik hegzaklorosiklohegzan’nın mekanokimyasal parçalanması

Volkan Pelitli, Uğur Kurt, Oltan Canlı

Gazi Üniversitesi Mühendislik-Mimarlık Fakültesi Dergisi.2018;[Epub] CrossRef - Parametric study on the production of the GAGG:Ce and LSO:Ce multicomponent oxide scintillator materials through use of a planetary ball mill

Kaitlyn A. McDonald, Matthew R. McDonald, Melissa N. Bailey, George K. Schweitzer

Dalton Transactions.2018; 47(37): 13190. CrossRef - Effect of Mechanical Activation on the In Situ Formation of TiB2 Particulates in the Powder Mixture of TiH2 and FeB

X.-K. Huynh, B.-W. Kim, J.S. Kim

Archives of Metallurgy and Materials.2017; 62(2): 1393. CrossRef - Effects of mechanical milling on the carbothermal reduction of oxide of WC/Co hardmetal scrap

Gil-Geun Lee, Gook-Hyun Ha

Metals and Materials International.2016; 22(2): 260. CrossRef

- Particle interactions during dry powder mixing and their effect on solvent-free manufactured electrode properties

- [English]

- Processing Methods for the Preparation of Porous Ceramics

- Rizwan Ahmad, Jang-Hoon Ha, In-Hyuck Song

- J Korean Powder Metall Inst. 2014;21(5):389-398. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.389

- 3,163 View

- 102 Download

- 22 Citations

-

Abstract

Abstract

PDF

PDF Macroporous ceramics with tailored pore size and shape could be used for well-established and emerging applications, such as molten metal filtration, biomaterial, catalysis, thermal insulation, hot gas filtration and diesel particulate filters. In these applications, unique properties of porous materials were required which could be achieved through the incorporation of macro-pores into ceramics. In this article, we reviewed the main processing techniques which can be used for the fabrication of macroporous ceramics with tailored microstructure. Partial sintering, replica templates, sacrificial fugutives, and direct foaming techniques was described here and compared in terms of micro-structures and mechanical properties that could be achieved. The main focus was given to the direct foaming technique which was simple and versatile approach that allowed the fabrication of macro-porous ceramics with tailored features and properties.

-

Citations

Citations to this article as recorded by- Contribution of microscale stochastic truss models to investigate the macroscale elasticity constants of porous ceramics

Thierry Canet, Gilles Dusserre, Thierry Cutard

European Journal of Mechanics - A/Solids.2025; 111: 105561. CrossRef - Synthesis and properties of high alumina cement-based porous composites in the ZrO2-CaO-Al2O3 system

Yesica L. Bruni, María F. Hernández, Susana Conconi, Gustavo Suárez

Ceramics International.2025; 51(23): 39794. CrossRef - Morphology and phase analysis of cordierite ceramic foams with Ag nanoparticles

J. Kupková, G. Kratošová, K. Čech Barabaszová, G. Simha Martynková

IOP Conference Series: Materials Science and Engineering.2025; 1337(1): 012004. CrossRef - Organic waste-derived pore formers for macroporous ceramics fabrication: A review on synthesis, durability properties and potential applications

T.T. Dele-Afolabi, M.A. Azmah Hanim, A.A. Oyekanmi, M.N.M. Ansari, Surajudeen Sikiru, O.J. Ojo-Kupoluyi

Materials Today Sustainability.2024; 27: 100824. CrossRef - Chemistry and Physics of Wet Foam Stability for Porous Ceramics: A Review

Kamrun Nahar Fatema, Md Rokon Ud Dowla Biswas, Jung Gyu Park, Ik Jin Kim

Micro.2024; 4(4): 552. CrossRef - Investigating mass transfer coefficients in lean methane combustion reaction through the morphological and geometric analysis of structured open cell foam catalysts

Carmen W. Moncada Quintero, Hernan G. Mazzei, Marion Servel, Frédéric Augier, Yacine Haroun, Jean-François Joly, Stefania Specchia

Chemical Engineering Science.2023; 281: 119138. CrossRef - Composite PLGA–Nanobioceramic Coating on Moxifloxacin-Loaded Akermanite 3D Porous Scaffolds for Bone Tissue Regeneration

Georgia K. Pouroutzidou, Lambrini Papadopoulou, Maria Lazaridou, Konstantinos Tsachouridis, Chrysanthi Papoulia, Dimitra Patsiaoura, Ioannis Tsamesidis, Konstantinos Chrissafis, George Vourlias, Konstantinos M. Paraskevopoulos, Antonios D. Anastasiou, Dim

Pharmaceutics.2023; 15(3): 819. CrossRef - Development of high strength large open porosity alumina ceramics using the sacrificial phase route: The role of the sacrificial phase fineness

Julian Alzukaimi, Rafi Jabrah

Ceramics International.2023; 49(2): 2923. CrossRef - Sustainable nanocomposite porous absorbent and membrane sieves: Definition, classification, history, properties, synthesis, applications, and future prospects

Sameer Ahmad, Weqar Ahmad Siddiqi, Sharif Ahmad

Journal of Environmental Chemical Engineering.2023; 11(2): 109367. CrossRef - Processing and characterization of porous composites based on CaAl4O7/CaZrO3

Yesica L. Bruni, María S. Conconi, María F. Hernández, Gustavo Suárez

Ceramics International.2023; 49(23): 37630. CrossRef - Trace addition of cellulose nanofiber in gel-casting system for structurally controlled porous ceramics towards superior thermal-insulating property

Yunzi Xin, Takashi Shirai

Journal of the Ceramic Society of Japan.2022; 130(5): 355. CrossRef - State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

Ismail Barbaros, Yongmin Yang, Babak Safaei, Zhicheng Yang, Zhaoye Qin, Mohammed Asmael

Nanotechnology Reviews.2022; 11(1): 321. CrossRef - A review of petroleum emulsification types, formation factors, and demulsification methods

Ahmed Abdulrazzaq Hadi, Ali Abdulkhabeer Ali

Materials Today: Proceedings.2022; 53: 273. CrossRef - SLURRY OPTIMISATION FOR FAST FREEZE-DRYING OF POROUS ALUMINA

Kritkaew Somton

Ceramics - Silikaty.2021; : 368. CrossRef - Recycling food, agricultural, and industrial wastes as pore-forming agents for sustainable porous ceramic production: A review

Siti Zuliana Salleh, Afiqah Awang Kechik, Abdul Hafidz Yusoff, Mustaffa Ali Azhar Taib, Maryana Mohamad Nor, Mardawani Mohamad, Tse Guan Tan, Arlina Ali, Mohamad Najmi Masri, Julie Juliewatty Mohamed, Siti Koriah Zakaria, Jia Geng Boon, Faisal Budiman, Pa

Journal of Cleaner Production.2021; 306: 127264. CrossRef - Novel noble-metal-free ceramic filter with controlled pore structure for environmental cleaning

Yunzi Xin, Sohei Nakagawa, Harumitsu Nishikawa, Takashi Shirai

Ceramics International.2021; 47(8): 11819. CrossRef - Fabrication of porous titania sheet via tape casting: Microstructure and water permeability study

Saber Ghannadi, Hossein Abdizadeh, Alireza Babaei

Ceramics International.2020; 46(7): 8689. CrossRef - Farklı Bağlayıcı ve Sinterleme Katkılarının SiC Seramik Prefom Mikroyapısı Üzerine Etkisi

Ebru Yılmaz, Fatih Çalışkan

Academic Perspective Procedia.2019; 2(3): 1309. CrossRef - The preparation and characterization of porous alumina ceramics using an eco‐friendly pore‐forming agent

Julian Alzukaimi, Rafi Jabrah

International Journal of Applied Ceramic Technology.2019; 16(2): 820. CrossRef - Wet Foam Stability from Colloidal Suspension to Porous Ceramics: A Review

Ik Jin Kim, Jung Gyu Park, Young Han Han, Suk Young Kim, James F. Shackelford

Journal of the Korean Ceramic Society.2019; 56(3): 211. CrossRef - Processing of porous alumina by foaming method-effect of foaming agent, solid loading and binder

Soumya Devavarapu, Paritosh Chaudhuri, Aroh Shrivastava, Santanu Bhattacharyya

Ceramics International.2019; 45(9): 12264. CrossRef - Macroporous flexible polyvinyl alcohol lithium adsorbent foam composite prepared via surfactant blending and cryo-desiccation

Grace M. Nisola, Lawrence A. Limjuco, Eleazer L. Vivas, Chosel P. Lawagon, Myoung Jun Park, Ho Kyong Shon, Neha Mittal, In Wook Nah, Hern Kim, Wook-Jin Chung

Chemical Engineering Journal.2015; 280: 536. CrossRef

- Contribution of microscale stochastic truss models to investigate the macroscale elasticity constants of porous ceramics

- [Korean]

- Fabrication and Properties of Alloy Foam Materials using Metal Powders

- James Choi, Ku-Hwan Kim

- J Korean Powder Metall Inst. 2010;17(6):489-493.

- DOI: https://doi.org/10.4150/KPMI.2010.17.6.489

- 622 View

- 8 Download

- 15 Citations

-

Abstract

Abstract

PDF

PDF - Nickel-based and iron-based alloys have been developed and commercialized for a wide range of high performance applications at severely corrosive and high temperature environment. This alloy foam has an outstanding performance which is predestinated for diesel particulate filters, heat exchangers, and catalyst support, noise absorbers, battery, fuel cell, and flame distributers in burners in chemical and automotive industry. Production of alloy foam starts from high-tech coating technology and heat treatment of transient liquid-phase sintering in the high temperature. These technology allow for preparation of a wide variety of foam compositions such as Ni, Cr, Al, Fe on various pore size of pure nickel foam or iron foam in order for tailoring material properties to a specific application.

-

Citations

Citations to this article as recorded by- A novel approach to fabricating SUS 316L steel foam using material extrusion additive manufacturing technology

Noh-Geon Song, So-Yeon Park, Jung-Yeul Yun, Ju-Yong Kim, Kee-Ahn Lee

Journal of Materials Research and Technology.2025; 36: 8219. CrossRef - Fabrication and High-Temperature Compressive Behavior of Unique Multi-Sheet Stacked Block Ni–Cr–Al Metallic Foam

Kyu-Sik Kim, Tae-Hoon Kang, Man-Ho Park, Kee-Ahn Lee

Metals and Materials International.2021; 27(5): 1138. CrossRef - Fabrication and Mechanical Properties of Open‐Cell Austenitic Stainless Steel Foam by Electrostatic Powder Spraying Process

Tae-Hoon Kang, Kyu-Sik Kim, Jung-Yeul Yun, Min-Jeong Lee, Kee-Ahn Lee

Advanced Engineering Materials.2020;[Epub] CrossRef - Structural Characteristics, Microstructure and Mechanical Properties of Fe-Cr-Al Metallic Foam Fabricated by Powder Alloying Process

Kyu-Sik Kim, Byeong-Hoon Kang, Man-Ho Park, Jung-Yeul Yun, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(1): 37. CrossRef - Effect of Strain Rate and Loading Direction on the Mechanical Properties of Ni-Cr-Al Superalloy Foam Fabricated by Powder Alloying Method

Kyu-Sik Kim, Jung-Suk Bae, Jae-Sung Oh, Kee-Ahn Lee

Korean Journal of Metals and Materials.2020; 58(6): 375. CrossRef - Asymmetry in the Mechanical Properties of Block Ni-Cr-Al Superalloy Foam Fabricated by the Combination of Powder Alloying and Hot Rolling Processes

Kyu-Sik Kim, Min-Chul Shim, Man-Ho Park, Jung-Yeul Yun, Kee-Ahn Lee

Korean Journal of Metals and Materials.2020; 58(2): 103. CrossRef - A Study on Pore Properties of SUS316L Powder Porous Metal Fabricated by Electrostatic Powder Coating Process

Min-Jeong Lee, Yu-Jeong Yi, Hyeon-Ju Kim, Manho Park, Byoung-Kee Kim, Jung-Yeul Yun

Journal of Korean Powder Metallurgy Institute.2018; 25(5): 415. CrossRef - Microstructure and Tensile Deformation Behavior of Ni-Cr-Al Powder Porous Block Material

Chul-O Kim, Jung-Suk Bae, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2015; 22(2): 93. CrossRef - High temperature oxidation behavior of Ni-Cr-Al based powder porous metal

Jae-Sung Oh, Min-Chul Shim, Man-Ho Park, Kee-Ahn Lee

Metals and Materials International.2014; 20(5): 915. CrossRef - Effect of Cell Size on the High Temperature Oxidation Properties of Fe-Cr-Al Powder Porous Metal Manufactured by Electro-spray Process

Jae-Sung Oh, Young-Min Kong, Byoung-Kee Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2014; 21(1): 55. CrossRef - Effect of the pore size on the creep deformation behavior of Ni-Fe-Cr-Al porous metal

Kyu-Sik Kim, Jung-Yeol Yun, Baig-Gyu Choi, Kee-Ahn Lee

Metals and Materials International.2014; 20(3): 507. CrossRef - Effect of Pre-Oxidation on the High Temperature Oxidation Behavior of Fe-Cr-Al Powder Porous Metal

Jae Sung Oh, Seon Hui Lim, Sung Hwan Choi, Man Ho Park, Kee Ahn Lee

Advanced Materials Research.2013; 690-693: 294. CrossRef - Effect of Sintering Temperature on the High Temperature Oxidation of Fe-Cr-Al Powder Porous Metal Manufactured by Electrospray Process

Jae-Sung Oh, Young-Min Kong, Byoung-Kee Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2012; 19(6): 435. CrossRef - High Temperature Oxidation Behavior of Ni based Porous Metal

Sung-Hwan Choi, Jung-Yeul Yun, Hye-Mun Lee, Young-Min Kong, Byoung-Kee Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2011; 18(2): 122. CrossRef - Effect of Pore Formers and Sintering Temperatures on Microstructure and Bending Strength of the Porous Zirconia Ceramics

Eun-Jung Lee, In-Hyuck Song, Jang-Hoon Ha, Yoo-Dong Hahn, Yang-Do Kim

Journal of Korean Powder Metallurgy Institute.2011; 18(6): 502. CrossRef

- A novel approach to fabricating SUS 316L steel foam using material extrusion additive manufacturing technology

- [Korean]

- Overview and Future Concerns for Lithium-Ion Batteries Materials

- Hang-Chul Jung, Geon-Hong Kim, Hyun-Seon Hong, Dong-Wan Kim

- J Korean Powder Metall Inst. 2010;17(3):175-189.

- DOI: https://doi.org/10.4150/KPMI.2010.17.3.175

- 750 View

- 11 Download

- 14 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

Haein Shin, Kun-Jae Lee

Journal of Powder Materials.2024; 31(5): 374. CrossRef - Fabrication of Nanowire by Electrospinning Process Using Nickel Oxide Particle Recovered from MLCC

Haein Shin, Jongwon Bae, Minsu Kang, Kun-Jae Lee

journal of Korean Powder Metallurgy Institute.2023; 30(6): 502. CrossRef - Initial Behavior of Additives and Mechanical Properties of Copper Foils on High Current Density

Tae-Gyu Woo, Jong-Jae Park, Il-Song Park

Korean Journal of Metals and Materials.2021; 59(5): 304. CrossRef - Changes in Electrical Properties of Copper-Plated Layer by Organic Additives on High Current Density

Tae-Gyu Woo, Il-Song Park

Korean Journal of Metals and Materials.2020; 58(1): 41. CrossRef - A Study on the Recovery of Li<sub>2</sub>CO<sub>3</sub> from Cathode Active Material NCM(LiNiCoMnO<sub>2</sub>) of Spent Lithium Ion Batteries

Jei-Pil Wang, Jae-Jung Pyo, Se-Ho Ahn, Dong-Hyeon Choi, Byeong-Woo Lee, Dong-Won Lee

Journal of Korean Powder Metallurgy Institute.2018; 25(4): 296. CrossRef - Effect of Gelatin and Chloride Ions on the Mechanical Properties and Microstructural Evolution of Copper Foil

Tae-Gyu Woo, Man-Hyung Lee, Kyeong-Won Seol

Korean Journal of Metals and Materials.2018; 56(7): 518. CrossRef - Main Effects of Plating Parameters on Mechanical and Surface Properties of Electroplated Copper

Tae-Gyu Woo, Il-Song Park, Kyeong-Won Seol

Korean Journal of Metals and Materials.2018; 56(6): 459. CrossRef - Solvent Extraction of Co, Ni and Mn from NCM Sulfate Leaching Solution of Li(NCM)O2 Secondary Battery Scraps

Hyun Seon Hong, Dae Weon Kim, Hee Lack Choi, Sung-Soo Ryu

Archives of Metallurgy and Materials.2017; 62(2): 1011. CrossRef - The effect of additives and current density on mechanical properties of cathode metal for secondary battery

Tae-Gyu Woo, Il-Song Park, Kyeong-Won Seol

Electronic Materials Letters.2013; 9(4): 535. CrossRef - Recovery of Lithium and Leaching Behavior of NCM Powder by Carbon Reductive Treatment from Li(NCM)O2System Secondary Battery Scraps

Dae Weon Kim, Seong Tae Jang

Journal of the Korean Institute of Resources Recycling.2013; 22(4): 62. CrossRef - Recovery of Lithium and Leaching Behavior of NCM Powder by Hydrogen Reductive Treatment from NCM System Li-ion Battery Scraps

Dae Weon Kim, Seong Tae Jang, Kyung Min Baek

Journal of the Korean Institute of Resources Recycling.2013; 22(3): 43. CrossRef - Industrial Supply Chain Trend of Domestic Tungsten

Joon-Woo Song, Sang-Hyun Lee, Hyun-Seon Hong, Hong-Yoon Kang, Soon-Jik Hong

Journal of Korean Powder Metallurgy Institute.2012; 19(1): 79. CrossRef - Research and Development Status of Low-Cost Fe-based Cathode Materials for Lithium Secondary Batteries

Hyun-Seon Hong, Young-Dae Ko, Lee-Seung Kang, Hang-Chul Jung, Geon-Hong Kim

Journal of Korean Powder Metallurgy Institute.2011; 18(2): 196. CrossRef - Preparation of the Nano Cobalt Powder by Wet Chemical Reduction Method

Hyun-Seon Hong, Young-Dae Ko, Lee-Seung Kang, Geon-Hong Kim, Hang-Chul Jung

Journal of Korean Powder Metallurgy Institute.2011; 18(3): 244. CrossRef

- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

- [Korean]

- Effect of Porosity on Mechanical Anisotropy of 316L Austenitic Stainless Steel Additively Manufactured by Selective Laser Melting

- Jeong Min Park, Jin Myoung Jeon, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2018;25(6):475-481. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.475

- 1,075 View

- 12 Download

- 12 Citations

-

Abstract

Abstract

PDF

PDF Selective laser melting (SLM), a type of additive manufacturing (AM) technology, leads a global manufacturing trend by enabling the design of geometrically complex products with topology optimization for optimized performance. Using this method, three-dimensional (3D) computer-aided design (CAD) data components can be built up directly in a layer-by-layer fashion using a high-energy laser beam for the selective melting and rapid solidification of thin layers of metallic powders. Although there are considerable expectations that this novel process will overcome many traditional manufacturing process limits, some issues still exist in applying the SLM process to diverse metallic materials, particularly regarding the formation of porosity. This is a major processing-induced phenomenon, and frequently observed in almost all SLM-processed metallic components. In this study, we investigate the mechanical anisotropy of SLM-produced 316L stainless steel based on microstructural factors and highly-oriented porosity. Tensile tests are performed to investigate the microstructure and porosity effects on mechanical anisotropy in terms of both strength and ductility.

-

Citations

Citations to this article as recorded by- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

Tae Hyeong Kim, Haeum Park, Jun Seok Lee, Jeong Min Park, Jae Wung Bae

Materials Science and Engineering: A.2025; 933: 148286. CrossRef - Selective laser melting additive manufactured H13 tool steel for aluminum extrusion die component construction

Evangelos Giarmas, Vasileios Tsakalos, Emmanuel Tzimtzimis, Nikolaos Kladovasilakis, Ioannis Kostavelis, Dimitrios Tzovaras, Dimitrios Tzetzis

The International Journal of Advanced Manufacturing Technology.2024; 133(9-10): 4385. CrossRef - Nanoindentation Creep Behavior of Additively Manufactured H13 Steel by Utilizing Selective Laser Melting Technology

Evangelos Giarmas, Emmanouil K. Tzimtzimis, Nikolaos Kladovasilakis, Dimitrios Tzovaras, Dimitrios Tzetzis

Materials.2024; 17(15): 3756. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - Development of multi-defect diagnosis algorithm for the directed energy deposition (DED) process with in situ melt-pool monitoring

Hyewon Shin, Jimin Lee, Seung-Kyum Choi, Sang Won Lee

The International Journal of Advanced Manufacturing Technology.2023; 125(1-2): 357. CrossRef - Corrosion Resistance of Laser Powder Bed Fused AISI 316L Stainless Steel and Effect of Direct Annealing

Kichang Bae, Dongmin Shin, Jonghun Lee, Seohan Kim, Wookjin Lee, Ilguk Jo, Junghoon Lee

Materials.2022; 15(18): 6336. CrossRef - Experimental investigation on the effect of process parameters in additive/subtractive hybrid manufacturing 316L stainless steel

Chengming Tang, Jibin Zhao, Zhiguo Wang, Yuhui Zhao, Tianran Wang

The International Journal of Advanced Manufacturing Technology.2022; 121(3-4): 2461. CrossRef - Interface characteristics and mechanical behavior of additively manufactured multi-material of stainless steel and Inconel

Man Jae Sagong, Eun Seong Kim, Jeong Min Park, Gangaraju Manogna Karthik, Byeong-Joo Lee, Jung-Wook Cho, Chong Soo Lee, Takayoshi Nakano, Hyoung Seop Kim

Materials Science and Engineering: A.2022; 847: 143318. CrossRef - Effect of heat treatment on microstructural heterogeneity and mechanical properties of 1%C-CoCrFeMnNi alloy fabricated by selective laser melting

Jeong Min Park, Eun Seong Kim, Hyeonseok Kwon, Praveen Sathiyamoorthi, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim

Additive Manufacturing.2021; 47: 102283. CrossRef - Manufacturing Aluminum/Multiwalled Carbon Nanotube Composites via Laser Powder Bed Fusion

Eo Ryeong Lee, Se Eun Shin, Naoki Takata, Makoto Kobashi, Masaki Kato

Materials.2020; 13(18): 3927. CrossRef - Effects of microstructure and internal defects on mechanical anisotropy and asymmetry of selective laser-melted 316L austenitic stainless steel

Jin Myoung Jeon, Jeong Min Park, Ji-Hun Yu, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

Materials Science and Engineering: A.2019; 763: 138152. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef

- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

- [Korean]

- Effect of Powder Characteristic and Freeze Condition on the Pore Characteristics of Porous W

- Na-Yeon Kwon, Sung-Tag Oh

- J Korean Powder Metall Inst. 2012;19(4):259-263.

- DOI: https://doi.org/10.4150/KPMI.2012.19.4.259

- 698 View

- 1 Download

- 12 Citations

-

Abstract

Abstract

PDF

PDF - Dependence of the freeze-drying process condition on microstructure of porous W and pore formation mechanism were studied. Camphene slurries with WO_3 contents of 10 vol% were prepared by milling at 50°C with a small amount of dispersant. Freezing of a slurry was done in Teflon cylinder attached to a copper bottom plate cooled at -25°C. Pores were generated subsequently by sublimation of the camphene during drying in air for 48 h. The green body was hydrogen-reduced at 800°C for 30 min, and sintered in the furnace at 900°C for 1 h. After heat treatment in hydrogen atmosphere, WO_3 powders were completely converted to metallic W without any reaction phases. The sintered samples showed large pores with the size of about 70µm which were aligned parallel to the camphene growth direction. Also, the internal wall of large pores and near bottom part of specimen had relatively small pores with dendritic structure due to the growth of camphene dendrite depending on the degree of nucleation and powder rearrangement in the slurry.

-

Citations

Citations to this article as recorded by- Fabrication of Porous TiO2 with Aligned Pores Using Tert-Butyl Alcohol Based Freeze Casting

Eui Seon Lee, Sung-Tag Oh

Korean Journal of Metals and Materials.2024; 62(12): 929. CrossRef - Fabrication of Porous W-Ti by Freeze-Drying and Hydrogen Reduction of WO3-TiH2 Powder Mixtures

Hyunji Kang, Sung Hyun Park, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2017; 24(6): 472. CrossRef - Synthesis of Aligned Porous Sn by Freeze-Drying of Tin Chloride/camphene Slurry

수룡 방, 승탁 오

Korean Journal of Materials Research.2015; 25(1): 27~31. CrossRef - Effect of Sublimable Vehicle Compositions in the Camphor-NaphthaleneSystem on the Pore Structure of Porous Cu-Ni

Na-Yeon Kwon, Myung-Jin Suk, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2015; 22(5): 362. CrossRef - Porous Mo–30wt.% W alloys synthesized from camphene/MoO3–WO3 slurry by freeze drying and sintering process

Ki Cheol Jeon, Beom Seok Kim, Young Do Kim, Myung-Jin Suk, Sung-Tag Oh

International Journal of Refractory Metals and Hard Materials.2015; 53: 32. CrossRef - Fabrication of Porous Cu-Ni by Freeze Drying and Hydrogen Reduction of CuO-NiO Powder Mixture

Han Gil Seo, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2014; 21(1): 34. CrossRef - Synthesis of porous Cu–Sn using freeze-drying process of CuO–SnO2/camphene slurries

Sung-Tag Oh, Wonsuk Lee, Si Young Chang, Myung-Jin Suk

Research on Chemical Intermediates.2014; 40(7): 2495. CrossRef - Fabrication of Porous Cu by Freeze-drying Process of Camphene Slurry with CuO-coated Cu Powders

Su-Ryong Bang, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2014; 21(3): 191. CrossRef - Effect of Solidification Condition of Sublimable Vehicles on the Pore Characteristics in Freeze Drying Process

Myung-Jin Suk, Ji Soon Kim, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2014; 21(5): 366. CrossRef - Freeze Drying for Porous Mo with Sublimable Vehicles of Eutectic System

Gyu-Tae Lee, Han Gil Seo, Myung-Jin Suk, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2013; 20(4): 253. CrossRef - Synthesis of Porous Cu-Sn by Freeze Drying and Hydrogen Reduction Treatment of Metal Oxide Composite Powders

Min-Sung Kim, Ho-Suk Yoo, Sung-Tag Oh, Chang-Yong Hyun

Korean Journal of Materials Research.2013; 23(12): 722. CrossRef - Fabrication of Porous Mo by Freeze-Drying and Hydrogen Reduction of MoO3/Camphene Slurry

Wonsuk Lee, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2012; 19(6): 446. CrossRef

- Fabrication of Porous TiO2 with Aligned Pores Using Tert-Butyl Alcohol Based Freeze Casting

- [English]

- Electroexplosive Technology of Nanopowders Production: Current Status and Future Prospects

- Young-Soon Kwon, Jin-Chun Kim, Alexander P. Ilyin, Olga B. Nazarenko, Dmitry V. Tikhonov

- J Korean Powder Metall Inst. 2012;19(1):40-48.

- DOI: https://doi.org/10.4150/KPMI.2012.19.1.040

- 685 View

- 0 Download

- 11 Citations

-

Abstract

Abstract

PDF

PDF - The current situation of the nanopowders production technology based on the process of electrical explosion of wires is described. The advantages and disadvantages of the electroexplosive technology are indicated. The results of studies characterizing the effect of the electrical explosion conditions on the nanopowders properties are presented, including latest results: conditions of nanopowders passivation, conditions of nanopowders production having narrow size distribution, the methods of nanopowders diagnostic and standartization. In addition, the application and area of future research on this technology are proposed.

-

Citations

Citations to this article as recorded by- Characterization of Naturally Aged Iron Nanopowder Produced by Electrical Explosion of Wires

Olga B. Nazarenko, Alexander I. Sechin, Yuliya A. Amelkovich

Metals and Materials International.2021; 27(5): 962. CrossRef - Development of Effectual Substrates for SERS by Nanostructures-on flexible surfaces

Hammad R. Humud, Fatimah Jumaah Moaen

Journal of Physics: Conference Series.2021; 2114(1): 012084. CrossRef - Influence of Factors Affecting the Parameters of Combustion of Aluminum Nanopowders in the Bulk Layer

Alexander I. Sechin, Olga B. Nazarenko, Yuliya A. Amelkovich, Andrey A. Sechin

Materials Science Forum.2019; 970: 257. CrossRef - Effect of electron beam irradiation on thermal and mechanical properties of aluminum based epoxy composites

P.M. Visakh, O.B. Nazarenko, C. Sarath Chandran, T.V. Melnikova, S.Yu. Nazarenko, J.-C. Kim

Radiation Physics and Chemistry.2017; 136: 17. CrossRef - Investigation of coatings produced by the electrospark machining method of steel 45 with electrodes based on carbides of tungsten and titanium

S. V. Nikolenko, N. A. Syui

Protection of Metals and Physical Chemistry of Surfaces.2017; 53(5): 889. CrossRef - Influence of long-term storage on fire hazard properties of metal nanopowders

O S Kyrmakova, A I Sechin, O B Nazarenko

Journal of Physics: Conference Series.2017; 881: 012027. CrossRef - A Study of the Preparation and Properties of Antioxidative Copper Inks with High Electrical Conductivity

Chia-Yang Tsai, Wei-Chen Chang, Guan-Lin Chen, Cheng-Huan Chung, Jun-Xiang Liang, Wei-Yang Ma, Tsun-Neng Yang

Nanoscale Research Letters.2015;[Epub] CrossRef - Characterization of copper nanopowders after natural aging

Yu A Amelkovich, O B Nazarenko, A I Sechin, P M Visakh

IOP Conference Series: Materials Science and Engineering.2015; 81: 012072. CrossRef - Characterization of aluminum nanopowders after long-term storage

O.B. Nazarenko, Yu.A. Amelkovich, A.I. Sechin

Applied Surface Science.2014; 321: 475. CrossRef - Effect of the Gas Composition at the Electrical Explosion of Wires on the Nanopowders Properties

Olga B. Nazarenko, Alexander P. Ilyin, Dmitry V. Tikhonov

Advanced Materials Research.2013; 872: 142. CrossRef - Prospects of Using Nanopowders as Flame Retardant Additives

Olga B. Nazarenko, Yulia A. Amelkovich, Alexander P. Ilyin, Alexander I. Sechin

Advanced Materials Research.2013; 872: 123. CrossRef

- Characterization of Naturally Aged Iron Nanopowder Produced by Electrical Explosion of Wires

- [English]

- Mechanical Alloying and Milling

- C. Suryanarayana, In-Seop An

- J Korean Powder Metall Inst. 2006;13(5):371-372.

- DOI: https://doi.org/10.4150/KPMI.2006.13.5.371

- 848 View

- 23 Download

- 11 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Lemon extract supported green synthesis of bimetallic CuO/Ag nanoporous materials for sensitive detection of vitamin D3

Gowhar A. Naikoo, Fay M. Almashali, Fatima A. S. Habis, Mustri Bano, Jahangir Ahmad Rather, Israr U. Hassan, Rayees Ahmad Sheikh, Palanisamy Kannan, Iman M. Alfagih, Murtaza M. Tambuwala

Scientific Reports.2023;[Epub] CrossRef - Mechanochemical Synthesis of PZT Powders and the Effects of Mechanical Activation on Solid-State Sintering Kinetics

Bijesh Mehta, C. Sasikumar

Transactions of the Indian Institute of Metals.2023; 76(3): 849. CrossRef - Effect of Process Control Agent on Microstructures and High-Temperature Oxidation Behavior of a Nickel-Based ODS Alloy

Zhe Mao, Jing Li, Shi Liu, Liangyin Xiong

Metals.2022; 12(6): 1029. CrossRef - Synthesis of Fe–Al Intermetallic by Mechanical Alloying Process

Vivek Kumar Jain, Manoj Kumar Yadav, Arshad Noor Siddiquee, Zahid Akhtar Khan, Chaitanya Sharma

Journal of The Institution of Engineers (India): Series D.2022; 103(2): 621. CrossRef - Approaches on Ferrofluid Synthesis and Applications: Current Status and Future Perspectives

Oscar Oehlsen, Sussy I. Cervantes-Ramírez, Pabel Cervantes-Avilés, Illya A. Medina-Velo

ACS Omega.2022; 7(4): 3134. CrossRef - Polymorphism of the Co–Te nanophases in mechanochemical synthesis

Marcelo Augusto Malagutti, Vagner Zeizer Carvalho Paes, Julian Geshev, Carlos Eduardo Maduro de Campos

RSC Advances.2022; 12(52): 33488. CrossRef - The effect of milling time on the alumina phase transformation in the AMCs powder metallurgy reinforced by silica-sand-tailings

Sukanto, Wahyono Suprapto, Rudy Soenoko, Yudy Surya Irawan

EUREKA: Physics and Engineering.2022; (1): 103. CrossRef - Increase of the mechanical response of pure aluminum by grain refinement retained with an alternative rapid sintering route

J. M. Mendoza-Duarte, F. C. Robles-Hernandez, E. Rocha-Rangel, Y. Todaka, N. Adachi, I. Estrada-Guel, C. G. Garay-Reyes, M. A. Ruiz Esparza-Rodríguez, R. Martínez-Sánchez

Journal of Materials Research.2021; 36(6): 1328. CrossRef - Effect of the route and sintering time in the microstructure of pure aluminum prepared by high energy ball milling

José Mendoza, C. Carreño-Gallardo, I. Estrada-Guel, C.G. Garay-Reyes, M.A. Ruiz-Esparza-Rodriguez, G. Rodríguez-Cabriales, J.C Guía-Tello, R. Martínez-Sánchez

Microscopy and Microanalysis.2021; 27(S1): 3294. CrossRef - Optimization of friction stir processing parameters for enhanced microhardness of AA5083/Al-Fe in-situ composites via Taguchi technique

Vivek Kumar Jain, Manoj Kumar Yadav, Arshad Noor Siddiquee, Zahid A. Khan

Material Science, Engineering and Applications.2021; 1(2): 55. CrossRef - Carbide Nanoparticle Dispersion Techniques for Metal Powder Metallurgy

Bahrum Prang Rocky, Christopher R. Weinberger, Steven R. Daniewicz, Gregory B. Thompson

Metals.2021; 11(6): 871. CrossRef

- Lemon extract supported green synthesis of bimetallic CuO/Ag nanoporous materials for sensitive detection of vitamin D3

- [English]

- Synthesis and Compaction of Al-based Nanopowders by Pulsed Discharge Method

- Chang-Kyu Rhee, Geun-Hee Lee, Whung-Whoe Kim

- J Korean Powder Metall Inst. 2002;9(6):433-440.

- DOI: https://doi.org/10.4150/KPMI.2002.9.6.433

- 637 View

- 2 Download

- 11 Citations

-

Abstract

Abstract

PDF

PDF - Synthesis and compaction of Al-base nano powders by pulsed discharge method were investigated. The aluminum based powders with 50 to 200 nm of diameter were produced by pulsed wire evaporation method. The powders were covered with very thin oxide layer. The perspective process for the compaction and sintering of nanostructured metal-based materials stable in a wide temperature range can be seen in the densification of nano-sized metal powders with uniformly distributed hard ceramic particles. The promising approach lies in utilization of natural uniform mixtures of metal and ceramic phases, e.g. partially oxidized metal powders as fabricated in our synthesis method. Their particles consist of metal grains coated with oxide films. To construct a metal-matrix material from such powder, it is necessary to destroy the hard oxide coatings of particles during the compaction process. This goal was realized in our experiments with intensive magnetic pulsed compaction of aluminum nanopowders passivated in air.

-

Citations

Citations to this article as recorded by- Thermodynamic modeling and characterizations of Al nanoparticles produced by electrical wire explosion process

L. Santhosh Kumar, S.R. Chakravarthi, R. Sarathi, R. Jayaganthan

Journal of Materials Research.2017; 32(4): 897. CrossRef - Electrochemical properties of Sn/C nanoparticles fabricated by redox treatment and pulsed wire evaporation method

Ju-Seok Song, Gyu-Bong Cho, Jou-Hyeon Ahn, Kwon-Koo Cho

Applied Surface Science.2017; 415: 14. CrossRef - Investigation of Nano-Molybdenum Carbide Particle Produced by Wire-Explosion Process

Ramanujam Sarathi, Ravula Sugunakar Reddy, Rashmi S. Tavarmani, Akira Okamoto, Hisayuki Suematsu, Parasuraman Selvam, Uthandi Kamachi Mudali, Muthusamy Kamaraj

IEEE Transactions on Plasma Science.2015; 43(10): 3470. CrossRef - Synthesis and characterization of hexagonal nano tungsten carbide powder using multi walled carbon nanotubes

S. Aravinth, Binu Sankar, M. Kamaraj, S.R. Chakravarthy, R. Sarathi

International Journal of Refractory Metals and Hard Materials.2012; 33: 53. CrossRef - Synthesis and characterization of copper nanoparticles by using the exploding wire method

Rashmita Das, Basanta Kumar Das, Anurag Shyam

Journal of the Korean Physical Society.2012; 61(5): 710. CrossRef - Generation and characterization of nano-tungsten carbide particles by wire explosion process

B. Debalina, M. Kamaraj, B.S. Murthy, S.R. Chakravarthi, R. Sarathi

Journal of Alloys and Compounds.2010; 496(1-2): 122. CrossRef - Understanding the mechanism of nano-aluminum particle formation by wire explosion process using optical emission technique

Jobin K. Antony, Nilesh J. Vasa, S.R. Chakravarthy, R. Sarathi

Journal of Quantitative Spectroscopy and Radiative Transfer.2010; 111(17-18): 2509. CrossRef - Understanding nanoparticle formation by a wire explosion process through experimental and modelling studies

T K Sindhu, R Sarathi, S R Chakravarthy

Nanotechnology.2008; 19(2): 025703. CrossRef - Generation and characterization of nano aluminium powder obtained through wire explosion process

T. K. Sindhu, R. Sarathi, S. R. Chakravarthy

Bulletin of Materials Science.2007; 30(2): 187. CrossRef - Impact of binary gas on nano-aluminium particle formation through wire explosion process

R. Sarathi, T.K. Sindhu, S.R. Chakravarthy

Materials Letters.2007; 61(8-9): 1823. CrossRef - Generation of nano aluminium powder through wire explosion process and its characterization

R. Sarathi, T.K. Sindhu, S.R. Chakravarthy

Materials Characterization.2007; 58(2): 148. CrossRef

- Thermodynamic modeling and characterizations of Al nanoparticles produced by electrical wire explosion process

- [English]

- A Study on the Recovery of Li2CO3 from Cathode Active Material NCM(LiNiCoMnO2) of Spent Lithium Ion Batteries

- Jei-Pil Wang, Jae-Jung Pyo, Se-Ho Ahn, Dong-Hyeon Choi, Byeong-Woo Lee, Dong-Won Lee

- J Korean Powder Metall Inst. 2018;25(4):296-301. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.296

- 2,842 View

- 72 Download

- 10 Citations

-

Abstract

Abstract

PDF

PDF In this study, an experiment is performed to recover the Li in Li2CO3 phase from the cathode active material NMC (LiNiCoMnO2) in waste lithium ion batteries. Firstly, carbonation is performed to convert the LiNiO, LiCoO, and Li2MnO3 phases within the powder to Li2CO3 and NiO, CoO, and MnO. The carbonation for phase separation proceeds at a temperature range of 600°C~800°C in a CO2 gas (300 cc/min) atmosphere. At 600~700°C, Li2CO3 and NiO, CoO, and MnO are not completely separated, while Li and other metallic compounds remain. At 800 °C, we can confirm that LiNiO, LiCoO, and Li2MnO3 phases are separated into Li2CO3 and NiO, CoO, and MnO phases. After completing the phase separation, by using the solubility difference of Li2CO3 and NiO, CoO, and MnO, we set the ratio of solution (distilled water) to powder after carbonation as 30:1. Subsequently, water leaching is carried out. Then, the Li2CO3 within the solution melts and concentrates, while NiO, MnO, and CoO phases remain after filtering. Thus, Li2CO3 can be recovered.

-

Citations

Citations to this article as recorded by- Hydrogen Reduction of Black Mass Recovered from NCM-based Spent Lithium-ion Batteries

Jae-Ho Hwang, Sang-Yeop Lee, So-Yeong Lee, Ho-Sang Sohn

Resources Recycling.2025; 34(3): 34. CrossRef - Reduction Roasting of Cathode Materials of NCM Based Lithium-ion Batteries Using CH4(g)

Jae-Ho Hwang, Sang-Yeop Lee, Ho-Sang Sohn

Resources Recycling.2025; 34(4): 48. CrossRef - High‐Rate Rechargeable Li/SOCl2 Batteries Enabled by Cobalt Phthalocyanine Cathodic Catalysts

Yingxuan Song, Haibo Ouyang, Zhanwei Xu, Zeyang Zhang, Kang Li, Jianfeng Huang, Zhi Li, Tian Wang, Jun Yang

Small.2025;[Epub] CrossRef - Reduction Roasting of Black Mass Recovered from NCM-based Spent Lithium-ion Batteries Using CH4 Gas

Sang-Yeop Lee, Jae-Ho Hwang, Ho-Sang Sohn

Resources Recycling.2025; 34(5): 93. CrossRef - Metals Recovery from Spent Lithium-ion Batteries Cathode Via Hydrogen Reduction-water Leaching-carbothermic or Hydrogen Reduction Process

Tahereh Rostami, Behnam Khoshandam

Mining, Metallurgy & Exploration.2024; 41(3): 1485. CrossRef - Influence of Flow-Gas Composition on Reaction Products of Thermally Treated NMC Battery Black Mass

Christin Stallmeister, Bernd Friedrich

Metals.2023; 13(5): 923. CrossRef - Holistic Investigation of the Inert Thermal Treatment of Industrially Shredded NMC 622 Lithium-Ion Batteries and Its Influence on Selective Lithium Recovery by Water Leaching

Christin Stallmeister, Bernd Friedrich

Metals.2023; 13(12): 2000. CrossRef - Environmentally Friendly Recovery of Lithium from Lithium–Sulfur Batteries

Lilian Schwich, Bernd Friedrich

Metals.2022; 12(7): 1108. CrossRef - Early-Stage Recovery of Lithium from Tailored Thermal Conditioned Black Mass Part I: Mobilizing Lithium via Supercritical CO2-Carbonation

Lilian Schwich, Tom Schubert, Bernd Friedrich

Metals.2021; 11(2): 177. CrossRef - Exploring a green route for recycling spent lithium-ion batteries: Revealing and solving deep screening problem

Jiadong Yu, Quanyin Tan, Jinhui Li

Journal of Cleaner Production.2020; 255: 120269. CrossRef

- Hydrogen Reduction of Black Mass Recovered from NCM-based Spent Lithium-ion Batteries

- [English]

- Effect of Passivation on the Sintering Behavior of Submicron Nickel Powder Compacts for MLCC Application

- Gi-Young Jo, Kwi-Jong Lee, Suk-Joong L. Kang

- J Korean Powder Metall Inst. 2013;20(6):405-410.

- DOI: https://doi.org/10.4150/KPMI.2013.20.6.405

- 785 View

- 28 Download

- 10 Citations

-

Abstract

Abstract

PDF

PDF - During sintering of Ni-electrode multi-layer ceramic capacitors (MLCCs), the Ni electrode often becomes discontinuous because of its lower sintering temperature relative to that of BaTiO_3. In an attempt to retard the sintering of Ni, we introduced passivation of the Ni powder. To find the optimal passivation conditions, a thermogravimetric analysis (TGA) was conducted in air. After passivation at 250°C for 11 h in air, a nickel oxide shell with a thickness of 4-5 nm was formed on nickel nanoparticles of 180 nm size. As anticipated, densification of the compacts of the passivated Ni/NiO core-shell powder was retarded: the starting temperature of densification increased from sim400°C to sim600°C in a 97N_2-3H_2 (vol %) atmosphere. Grain growth was also retarded during sintering at temperatures of 750 and 1000°C. When the sintering atmosphere was changed from wet 99.93N_2-0.07H_2 to wet 99.98N_2-0.02H_2, the average grain size decreased at the same sintering temperature. The conductivity of the passivated powder sample sintered at 1150°C for 8 h in wet 99.93N_2-0.07H_2 was measured to be 3.9times104S/cm, which is comparable with that, 4.6times104S/cm, of the Ni powder compact without passivation. These results demonstrate that passivation of Ni is a viable means of retarding sintering of a Ni electrode and hence improving its continuity in the fabrication of BaTiO_3-based multi-layer ceramic capacitors.

-

Citations

Citations to this article as recorded by- In-situ Stress Analysis of Nickel Nanoparticle Sintering with Metal Additive in Multi-Layer Ceramic Capacitors

Youngran Jung, Wonhyo Joo, Kyung Rul Lee, Cheol Kim, Min-Jung Choi, Young-Chang Joo, So-Yeon Lee

Electronic Materials Letters.2025; 21(3): 464. CrossRef - In-situ preparation of Ni@BaTiO3 nanocapsules for MLCCs by DC arc plasma

Yi-Long Wang, Zhi-Dong Dai, Guang-Long Wei, Xi-Yang Li, Xing-Long Dong, Xing-Hao Qu, Youngguan Jung

Journal of Alloys and Compounds.2025; 1037: 182251. CrossRef - In-situ preparation of Ni@ZrO2 nanocapsules powder by DC arc plasma for internal electrode of MLCC

Xi-Yang Li, Xing-Hao Qu, Dong Liu, Guang-Yun Zhu, Xing-Long Dong, Youngguan Jung

Vacuum.2024; 224: 113130. CrossRef - Effect of Sn addition on the low temperature shrinkage of Ni nanoparticles

Jongwon Lee, Hyung-Ho Kim, Hyunwoong Na, Jeongryeol Kim, Seong-Hyeon Hong

Ceramics International.2024; 50(4): 6793. CrossRef - Synthesis of Ni@MgO core–shell ultrafine particles for the fabrication of thick film electrodes

Liubin Shi, Hao Deng, Yuanzhi Chen, Shilong Xiong, Jindong Li, Dong-Liang Peng

Advanced Powder Technology.2024; 35(10): 104642. CrossRef - Effect of Adding W Nanopowder to Inhibit Sintering of Ni Nanopowder for MLCC

Joonwoon Lee, Guensik Min, Sungmin Lee, Yunggyu Ann, Heung Nam Han

Korean Journal of Metals and Materials.2024; 62(10): 777. CrossRef - Research Trends on the Influence of Oxygen Vacancies in Post BaTiO3 (BT) Ceramics for Next-Generation MLCCs

Intae Seo, Ka-Young Lee, Cheol-Min Oh, Hyoung-Won Kang

Ceramist.2023; 26(2): 172. CrossRef - Coating Ni particles to preserve their conductivity during sintering in oxidizing atmospheres

Damoon Sohrabi Baba Heidary, Clive A. Randall

Chemical Engineering Journal.2016; 304: 1009. CrossRef - Redesigning Multilayer Ceramic Capacitors by Preservation of Electrode Conductivity and Localized Doping

Damoon Sohrabi Baba Heidary, Clive A. Randall

ACS Applied Materials & Interfaces.2016; 8(45): 31449. CrossRef - Study on the behavior of atomic layer deposition coatings on a nickel substrate at high temperature

Damoon Sohrabi Baba Heidary, Clive A Randall

Nanotechnology.2016; 27(24): 245701. CrossRef

- In-situ Stress Analysis of Nickel Nanoparticle Sintering with Metal Additive in Multi-Layer Ceramic Capacitors

- [English]

- Fabrication of Fe-TiB2 Composite Powder by High-Energy Milling and Subsequent Reaction Synthesis

- H.X. Khoa, N.Q. Tuan, Y.H. Lee, B.H. Lee, N.H. Viet, J.S. Kim

- J Korean Powder Metall Inst. 2013;20(3):221-227.

- DOI: https://doi.org/10.4150/KPMI.2013.20.3.221

- 716 View

- 5 Download

- 10 Citations

-

Abstract

Abstract

PDF

PDF - TiB_2-reinforced iron matrix composite (Fe-TiB_2) powder was in-situ fabricated from titanium hydride (TiH_2) and iron boride (FeB) powders by the mechanical activation and a subsequent reaction. Phase formation of the composite powder was identified by X-ray diffraction (XRD). The morphology and phase composition were observed and measured by field emission-scanning electron microscopy (FE-SEM) and energy-dispersive X-ray spectroscopy (EDS), respectively. The results showed that TiB_2 particles formed in nanoscale were uniformly distributed in Fe matrix. Fe_2B phase existed due to an incomplete reaction of Ti and FeB. Effect of milling process and synthesis temperature on the formation of composite were discussed.

-

Citations

Citations to this article as recorded by- Low temperature controllable synthesis of transition metal and rare earth borides mediated by molten salt

Xueyin Liu, Quanli Jia, Shaowei Zhang, William E. Lee

International Materials Reviews.2024; 69(2): 107. CrossRef - TiB2-Fe hard alloys obtained using SHS powders of the Ti-B-Fe system

O.K. Lepakova, O.A. Shkoda

International Journal of Refractory Metals and Hard Materials.2024; 125: 106915. CrossRef - In Situ Spark Plasma Sintering, Microstructure and Mechanical Properties of Fe-15Cr-2Mn-1.5Al Matrix Composites Reinforced with TiB2 and CrFeB

Jian Liu, Min Wu, Bin Wang, Wei Xu, Weiping Chen, Fangfang Liu

JOM.2023; 75(3): 886. CrossRef - Glass-Forming Ability and Magnetic Properties of Al82Fe16Ce2 and Al82Fe14Mn2Ce2 Alloys Prepared by Mechanical Alloying

Nguyen Hong Hai, Nguyen Hoang Viet, Nguyen Thi Hoang Oanh

Applied Sciences.2023; 14(1): 152. CrossRef - Powder metallurgy processed TiB2-reinforced steel matrix composites: a review

Silani Sahoo, Bharat Bhushan Jha, Animesh Mandal

Materials Science and Technology.2021; 37(14): 1153. CrossRef - Synthesis of Cu-based TiCx composites via in-situ reaction between CuxTi melt and dissolvable solid carbon

Lei Guo, Yang Yang, Xiaochun Wen, Han Gao, Zhe Wang, Zhancheng Guo

Powder Technology.2020; 362: 375. CrossRef - Microstructure and Electrical Property of Ex-Situ and In-Situ Copper Titanium Carbide Nanocomposites

Nguyen Hoang Viet, Nguyen Thi Hoang Oanh

Metals.2020; 10(6): 735. CrossRef - Mechanical and Wear Behaviour of Hot-Pressed 304 stainless Steel Matrix Composites Containing TiB2 Particles

Silani Sahoo, Bharat B. Jha, Tarasankar Mahata, Jyothi Sharma, Tammana S. R. Ch. Murthy, Animesh Mandal

Transactions of the Indian Institute of Metals.2019; 72(5): 1153. CrossRef - Effect of volume fraction of reinforcement phase on mechanical behavior of ultra-high-temperature composite consisting of iron matrix and TiB2 particulates

Babak Jahani, Mehdi Salimi Jazi, Fardad Azarmi, Andrew Croll

Journal of Composite Materials.2018; 52(5): 609. CrossRef - Impression creep behaviour of TiB2 particles reinforced steel matrix composites

S. Sahoo, B. B. Jha, T.S. Mahata, J. Sharma, T. S. R. Ch. Murthy, A. Mandal

Materials Science and Technology.2018; 34(16): 1965. CrossRef

- Low temperature controllable synthesis of transition metal and rare earth borides mediated by molten salt

- [Korean]

- Effect of Heat Treatment Environment on the Properties of Cold Sprayed Cu-15 at.%Ga Coating Material for Sputtering Target

- Byung-Chul Choi, Dong-Yong Park, Hyung-Jun Kim, Ik-Hyun Oh, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2011;18(6):552-561.

- DOI: https://doi.org/10.4150/KPMI.2011.18.6.552

- 607 View

- 0 Download

- 9 Citations

-

Abstract

Abstract

PDF

PDF - This study attempted to manufacture a Cu-15 at.%Ga coating layer via the cold spray process and investigated the effect of heat treatment environment on the properties of cold sprayed coating material. Three kinds of heat treatment environments, 5%H_2+argon, pure argon, and vacuum were used in this study. Annealing treatments were conducted at 200sim800°C/1 hr. With the cold sprayed coating layer, pure alpha-Cu and small amounts of Ga_2O_3 were detected in the XRD, EDS, EPMA analyses. Porosity significantly decreased and hardness also decreased with increasing annealing temperature. The inhomogeneous dendritic microstructure of cold sprayed coating material changed to the homogeneous and dense one (microstructural evolution) with annealing heat treatment. Oxides near the interface of particles could be reduced by heat treatment especially in vacuum and argon environments. Vacuum environment during heat treatment was suggested to be most effective one to improve the densification and purification properties of cold sprayed Cu-15 at.%Ga coating material.

-

Citations

Citations to this article as recorded by- Manufacturing of Large-Scale Cold-Sprayed Ta Target Material and Its Sputtering Property

Gi-Su Ham, Dong-Yeol Wi, Jun-Mo Yang, Kee-Ahn Lee

Journal of Thermal Spray Technology.2019; 28(8): 1974. CrossRef - Effect of Hot Isostatic Pressing on the Microstructure and Propertiesof Kinetic Sprayed Nb Coating Material

Ji-Hye Lee, Sangsun Yang, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2016; 23(1): 15. CrossRef - Fabrication and Microstructure/Properties of Bulk-typeTantalum Material by a Kinetic Spray Process

Ji-Hye Lee, Ji-Won Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2016; 23(1): 8. CrossRef - Effect of Heat Treatment Environment on the Microstructure and Properties of Kinetic Sprayed Tantalum Coating Layer

Ji-Hye Lee, Hyung-Jun Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2015; 22(1): 32. CrossRef - The Effect of Annealing Heat Treatment on the Microstructure and Macroscopic Properties of Kinetic-Sprayed Ta Coating Layer

Myeong Ju Lee, Jae Sung Oh, Hyung Jun Kim, Ik Hyun Oh, Kee Ahn Lee

Advanced Materials Research.2014; 893: 64. CrossRef - Manufacturing of Cu Repair Coating Material Using the Kinetic Spray Process and Changes in the Microstructures and Properties by Heat Treatment

Min-Gwang Jeon, Hyung-Jun Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2014; 21(5): 349. CrossRef - Manufacturing and Properties of CGI-based Composite Coating Layer Utilizing a Warm Spray Process and Cu-Ga and Cu-In Mixed Powders

Min-Gwang Jeon, Myeong-Ju Lee, Hyeong-Jun Kim, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2014; 21(3): 229. CrossRef - Effect of Heat Treatment Environment on the Densification of Cold Sprayed Ti Coating Layer

Ji-Sang Yu, Hyung-Jun Kim, Ik-Hyun Oh, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2012; 19(2): 110. CrossRef - Sintering and Rolling Behavior of Cu-50In-13Ga Ternary Alloy Powder for Sputtering Target

Dae-Won Kim, Yong-Ho Kim, Jung-Han Kim, Dae-Guen Kim, Jong-Hyeon Lee, Kwang-Bo Choi, Hyeon-Taek Son

Journal of Korean Powder Metallurgy Institute.2012; 19(4): 264. CrossRef

- Manufacturing of Large-Scale Cold-Sprayed Ta Target Material and Its Sputtering Property

- [Korean]

- Production and Properties of Ag Metallic Nanoparticle Fluid by Electrical Explosion of Wire in Liquid

- E.J. Park, L.H. Bac, J.S. Kim, Y.S. Kwon, J.C. Kim, H.S. Choi, Y.H. Chung

- J Korean Powder Metall Inst. 2009;16(3):217-222.

- DOI: https://doi.org/10.4150/KPMI.2009.16.3.217

- 756 View

- 0 Download

- 9 Citations

-

Abstract

Abstract

PDF

PDF - This paper presents a novel single-step method to prepare the Ag nanometallic particle dispersed fluid (nanofluid) by electrical explosion of wire in liquid, deionized water (DI water). X-ray diffraction (XRD), field emission scanning electron microscope (FE-SEM) and transmission electron microscope (TEM) were used to investigate the characteristics of the Ag nanofluids. Zeta potential was also used to measure the dispersion properties of the as-prepared Ag nanofluid. Pure Ag phase was detected in the nanofluids using water. FE-SEM analysis shows that the size of the particles formed in DI water was about 88 nm and Zeta potential value was about -43.68 without any physical and chemical treatments. Thermal conductivity of the as-prepared Ag particle dispersed nanofluid shows much higher value than that of pure DI water.

-

Citations

Citations to this article as recorded by- Synthesis and Characterization of Cu Nanoparticles by Wire Explosion Technique for Antibacterial Applications

Bilal K. Al-Rawi, Safaa Mustafa Hameed, Sundus Alzuhairi

BioNanoScience.2025;[Epub] CrossRef - Synthesis and Characterizations of Physical and Antibacterial Properties of the Ag Nanoparticles by Exploding of Wire Technique

Abdulkareem M. Hussain, Bilal K. Al-Rawi

International Journal of Nanoscience.2024;[Epub] CrossRef - Enhancing adsorption efficiency for environmentally-friendly removal of As(V) and Pb(II) using a biochar-iron oxide composite

Soo Hyeon Kim, Ji-In Park, Seungsoo Lee, Ha-Rim An, Hyeran Kim, Byoungchul Son, Jiwon Seo, ChangYeon Kim, Yesul Jeong, Kyuseok Choi, Seulki Jeong, Hyun Uk Lee

Applied Surface Science.2024; 667: 160348. CrossRef - The Impact of Particle Size and Surface Treatment of Zirconia Suspension for Photocuring Additive Manufacturing

Mee-Jin Jun, Jin-Ho Kang, Kumaresan Sakthiabirami, Seyed Aliakbar Hosseini Toopghara, Ye-Seul Kim, Kwi-Dug Yun, Sang-Won Park

Materials.2023; 16(4): 1670. CrossRef - Analysis of Physicochemical Properties of Red Ginseng Powder Based on Particle Size

Hee Jeong Choi, Sang Yoon Lee, Jung Gyu Lee, Dong Hyeon Park, Jing Jing Bai, Byung-Joo Lee, Yoon-Sun Kim, Youngjae Cho, Mi-Jung Choi

Food Engineering Progress.2017; 21(3): 225. CrossRef - Preparation and Characteristics of Fluorinated Carbon Nanotube Applied Capacitive Desalination Electrode with Low Energy Consumption

Hyun-woo Yoo, Ji-hyun Kang, Nam-soo Park, Tae-il Kim, Min-Il Kim, Young-Seak Lee

Applied Chemistry for Engineering.2016; 27(4): 386. CrossRef - Critical heat flux characteristics of nanofluids based on exfoliated graphite nanoplatelets (xGnPs)

Eun Ju Park, Sung Dae Park, In Cheol Bang, Young-Bin Park, Hyung Wook Park

Materials Letters.2012; 81: 193. CrossRef - Platinum nanoparticles reduce ovariectomy-induced bone loss by decreasing osteoclastogenesis

Woon-Ki Kim, Jin-Chun Kim, Hyun-Jung Park, Ok-Joo Sul, Mi-Hyun Lee, Ji-Soon Kim, Hye-Seon Choi

Experimental & Molecular Medicine.2012; 44(7): 432. CrossRef - Optimal synthesis and characterization of Ag nanofluids by electrical explosion of wires in liquids

Eun Ju Park, Seung Won Lee, In Cheol Bang, Hyung Wook Park

Nanoscale Research Letters.2011;[Epub] CrossRef

- Synthesis and Characterization of Cu Nanoparticles by Wire Explosion Technique for Antibacterial Applications

- [Korean]

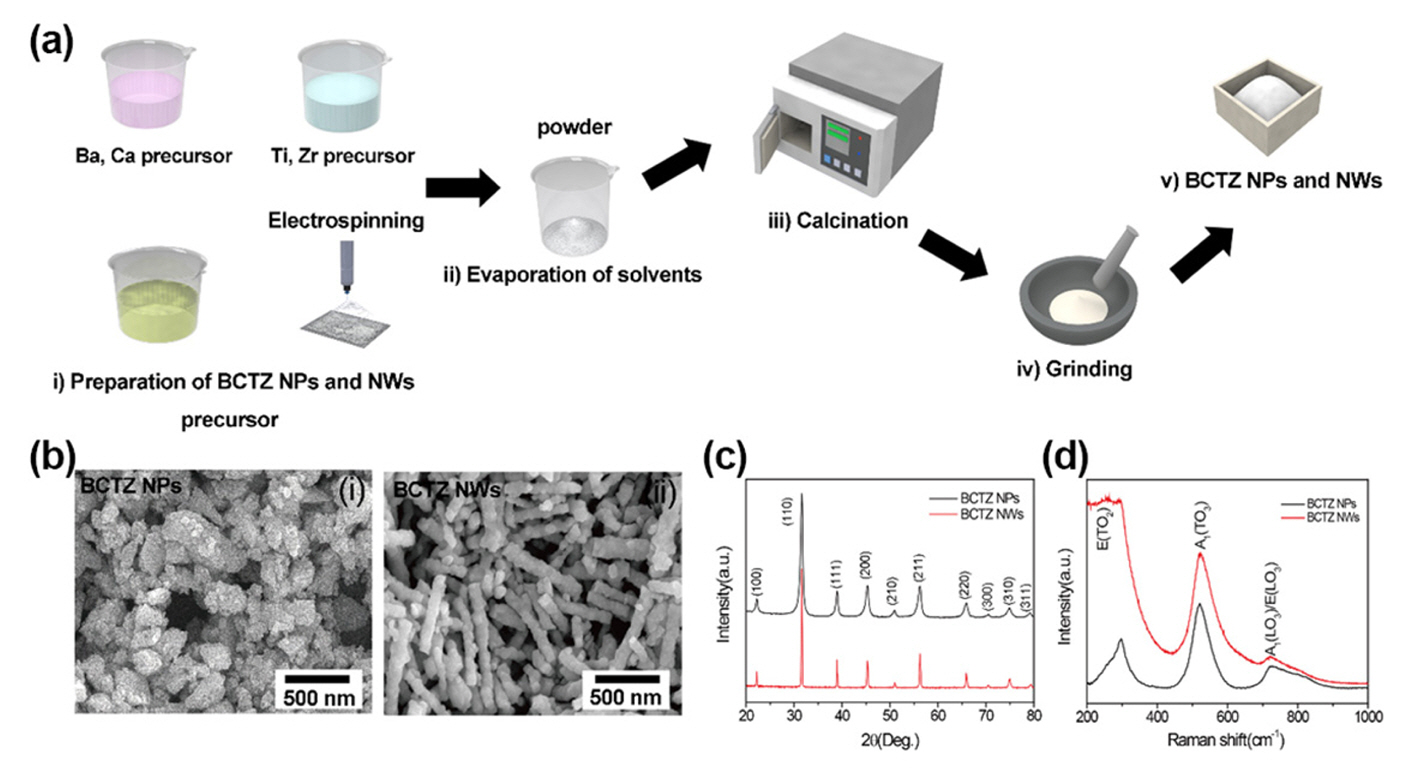

- Development of Composite-film-based Flexible Energy Harvester using Lead-free BCTZ Piezoelectric Nanomaterials

- Gwang Hyeon Kim, Hyeon Jun Park, Bitna Bae, Haksu Jang, Cheol Min Kim, Donghun Lee, Kwi-Il Park

- J Powder Mater. 2024;31(1):16-22. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.16

- 1,372 View

- 30 Download

- 8 Citations

-

Abstract

Abstract

PDF

PDF - Composite-based piezoelectric devices are extensively studied to develop sustainable power supply and selfpowered devices owing to their excellent mechanical durability and output performance. In this study, we design a leadfree piezoelectric nanocomposite utilizing (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 (BCTZ) nanomaterials for realizing highly flexible energy harvesters. To improve the output performance of the devices, we incorporate porous BCTZ nanowires (NWs) into the nanoparticle (NP)-based piezoelectric nanocomposite. BCTZ NPs and NWs are synthesized through the solidstate reaction and sol-gel-based electrospinning, respectively; subsequently, they are dispersed inside a polyimide matrix. The output performance of the energy harvesters is measured using an optimized measurement system during repetitive mechanical deformation by varying the composition of the NPs and NWs. A nanocomposite-based energy harvester with 4:1 weight ratio generates the maximum open-circuit voltage and short-circuit current of 0.83 V and 0.28 A, respectively. In this study, self-powered devices are constructed with enhanced output performance by using piezoelectric energy harvesting for application in flexible and wearable devices.

-

Citations

Citations to this article as recorded by- Long‐Lasting, Steady and Enhanced Energy Harvesting by Inserting a Conductive Layer into the Piezoelectric Polymer

HakSu Jang, Gwang Hyeon Kim, Dong Won Jeon, Hyeon Jun Park, BitNa Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Changyeon Baek, Min‐Ku Lee, Sung Beom Cho, Gyoung‐Ja Lee, Kwi‐Il Park

Advanced Functional Materials.2025;[Epub] CrossRef - Flexible hybrid thermoelectric films made of bismuth telluride-PEDOT:PSS composites enabled by freezing-thawing process and simple chemical treatment

Cheol Min Kim, Seoha Kim, Nagamalleswara Rao Alluri, Bitna Bae, Momanyi Amos Okirigiti, Gwang Hyun Kim, Hyeon Jun Park, Haksu Jang, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Materials Today Chemistry.2025; 44: 102532. CrossRef - Dual-controlled piezoelectric composite film with enhanced crystallinity and defect-free via solvent vapor treatment

HakSu Jang, Hyeon Jun Park, Gwang Hyeon Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, BitNa Bae, HyoMin Jeon, DongHun Lee, Kwi-Il Park

Nano Energy.2025; 136: 110705. CrossRef - Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

Journal of Powder Materials.2025; 32(1): 16. CrossRef - Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

Journal of Powder Materials.2025; 32(2): 104. CrossRef - Flexible Thermoelectric Energy Harvester with Stacked Structure of Thermoelectric Composite Films Made of PVDF and Bi2Te3-Based Particles

Da Eun Shin, Nagamalleswara Rao Alluri, Kwi-Il Park

ACS Applied Energy Materials.2024; 7(19): 8288. CrossRef - Enhanced energy harvesting of fibrous composite membranes via plasma-piezopolymer interaction

Hyeon Jun Park, Bitna Bae, HakSu Jang, Dong Yeol Hyeon, Dong Hun Lee, Gwang Hyun Kim, Cheol Min Kim, Nagamalleswara Rao Alluri, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Nano Energy.2024; 131: 110299. CrossRef - CoFe2O4-BaTiO3 core-shell-embedded flexible polymer composite as an efficient magnetoelectric energy harvester

Bitna Bae, Nagamalleswara Rao Alluri, Cheol Min Kim, Jungho Ryu, Gwang Hyeon Kim, Hyeon Jun Park, Changyeon Baek, Min-Ku Lee, Gyoung-Ja Lee, Geon-Tae Hwang, Kwi-Il Park

Materials Today Physics.2024; 48: 101567. CrossRef

- Long‐Lasting, Steady and Enhanced Energy Harvesting by Inserting a Conductive Layer into the Piezoelectric Polymer

- [English]

- Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

- Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

- J Powder Mater. 2024;31(1):1-7. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.1

- 5,115 View

- 122 Download

- 8 Citations

-

Abstract

Abstract

PDF

PDF This study explores the profound impact of varying oxygen content on microstructural and mechanical properties in specimens HO and LO. The higher oxygen concentration in specimen HO is found to significantly influence alpha lath sizes, resulting in a size of 0.5-1 μm, contrasting with the 1-1.5 μm size observed in specimen LO. Pore fraction, governed by oxygen concentration, is high in specimen HO, registering a value of 0.11%, whereas specimen LO exhibits a lower pore fraction (0.02%). Varied pore types in each specimen further underscore the role of oxygen concentration in shaping microstructural morphology. Despite these microstructural variations, the average hardness remains consistent at ~370 HV. This study emphasizes the pivotal role of oxygen content in influencing microstructural features, contributing to a comprehensive understanding of the intricate interplay between elemental composition and material properties.

-

Citations

Citations to this article as recorded by- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

Hadiseh Esmaeilpoor, Mahdi Aghaahmadi, Hyun Jong Yoo, Chan Woong Park, Tae Jin Jang, Seok Su Sohn, Jeoung Han Kim

Journal of Materials Science & Technology.2025; 213: 223. CrossRef - High-integrity diffusion bonding of laser powder bed fused, forged, and rolled Ti–6Al–4V alloys

Seoyeon Jeon, Hyunjong Ha, Dong Jun Lee, Hyeonil Park, Yong Nam Kwon, Hyunjoo Choi, Hyokyung Sung

Journal of Materials Research and Technology.2025; 35: 2108. CrossRef - Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Obtaining functionally-graded metal-matrix materials Ti‒6Al‒4V + WC in the process of 3D printing by the method of additive plasma-arc deposition

V. Korzhyk, A. Grynyuk, O. Babych, O. Berdnikova, Ye. Illiashenko, O. Bushma

The Paton Welding Journal.2025; 2025(8): 29. CrossRef - Obtaining functionally-graded metal-matrix materials ti‒6al‒4v + wc by the method of additive plasma-arc deposition

V.M. Korzhyk, A.A. Grynyuk, O.A. Babych, O.M. Berdnikova, Ye.V. Illiashenko, O.I. Bushma

Avtomatičeskaâ svarka (Kiev).2025; 2025(5): 48. CrossRef - Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

Journal of Powder Materials.2024; 31(5): 365. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Mechanical response and microstructural evolution of a composite joint fabricated by green laser dissimilar welding of VCoNi medium entropy alloy and 17-4PH stainless steel

- [Korean]

- Review on Characterization Method and Recent Research Trend about Metal Powder for Powder Bed Fusion (PBF) Process

- Bin Lee, Dae-Kyeom Kim, Young Il Kim, Do Hoon Kim, Yong Son, Kyoung-Tae Park, Taek-Soo Kim

- J Korean Powder Metall Inst. 2020;27(6):509-519. Published online December 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.6.509

- 997 View

- 9 Download

- 8 Citations

-

Abstract

Abstract

PDF

PDF A well-established characterization method is required in powder bed fusion (PBF) metal additive manufacturing, where metal powder is used. The characterization methods from the traditional powder metallurgy process are still being used. However, it is necessary to develop advanced methods of property evaluation with the advances in additive manufacturing technology. In this article, the characterization methods of powders for metal PBF are reviewed, and the recent research trends are introduced. Standardization status and specifications for metal powder for the PBF process which published by the ISO, ASTM, and MPIF are also covered. The establishment of powder characterization methods are expected to contribute to the metal powder industry and the advancement of additive manufacturing technology through the creation of related databases.

-

Citations

Citations to this article as recorded by-

Enhanced flow properties of SiO

2

nanoparticles coated low-cost hydrogenation-dehydrogenation Ti-6Al-4V powder for powder bed fusion process

Ukju Gim, Sehun Kim, Tae hu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

Powder Metallurgy.2025; 68(2): 95. CrossRef -

SiO

2

nanoparticle-coated Ti-6Al-4V spherical powder for powder bed fusion additive manufacturing process

Jongik Lee, Taehoo Kang, Ukju Gim, Sehun Kim, Sanghee Jung, Jimin Han, Bin Lee

Powder Metallurgy.2025; 68(4): 333. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Cost-effective Fabrication of Near β-Ti Alloy via L-PBF: Process Optimization of In-situ Alloying Ti-3Fe

Sehun Kim, Ukju Gim, Taehu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

Journal of Powder Materials.2025; 32(4): 288. CrossRef - A Study on Fabrication of PCD Endmill Holder using PBF Additive Manufacturing Technology

Min-Woo Sa, Ho-Min Son, Kyung-Hwan Park, Sang-Geun Lee, Dae-Ho Shin, Dong-Gyu Kim

Journal of the Korean Society of Manufacturing Process Engineers.2024; 23(6): 124. CrossRef - Rheological Characteristic Analysis Methods and Tests of Metal Powders for PBF Additive Manufacturing

Wan-Sik Woo, Ho-Jin Lee

Journal of the Korean Society of Manufacturing Process Engineers.2023; 22(10): 1. CrossRef - Residual Stress Analysis of Additive Manufactured A356.2 Aluminum Alloys using X-Ray Diffraction Methods

SangCheol Park, InYeong Kim, Young Il Kim, Dae-Kyeom Kim, Soong Ju Oh, Kee-Ahn Lee, Bin Lee

Korean Journal of Metals and Materials.2023; 61(7): 534. CrossRef - Enhancing spreadability of hydrogenation-dehydrogenation titanium powder and novel method to characterize powder spreadability for powder bed fusion additive manufacturing