Search

- Page Path

- HOME > Search

- [English]

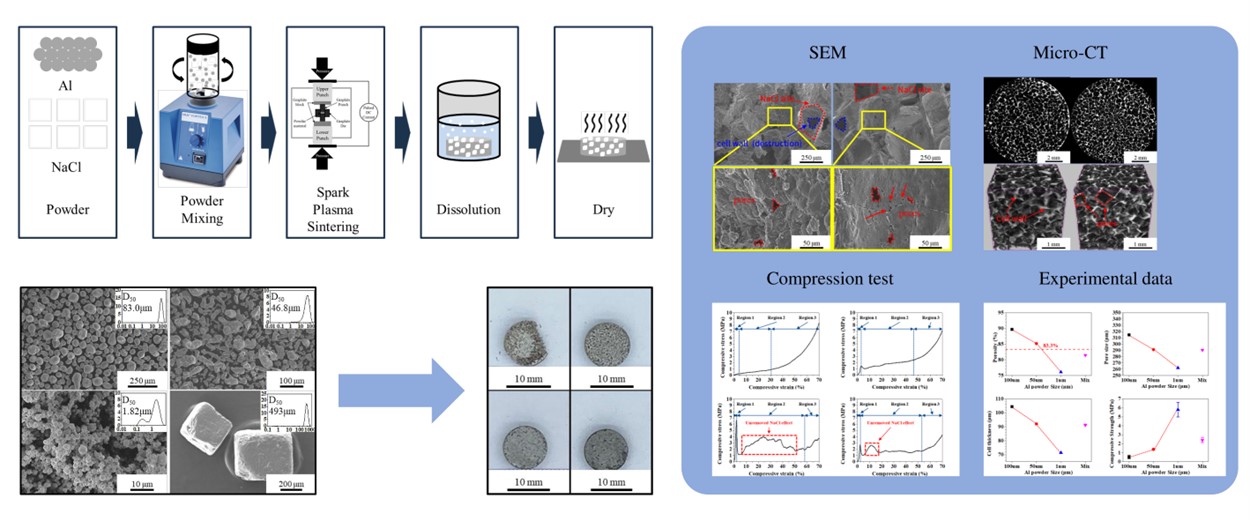

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 59 View

- 5 Download

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

- [Korean]

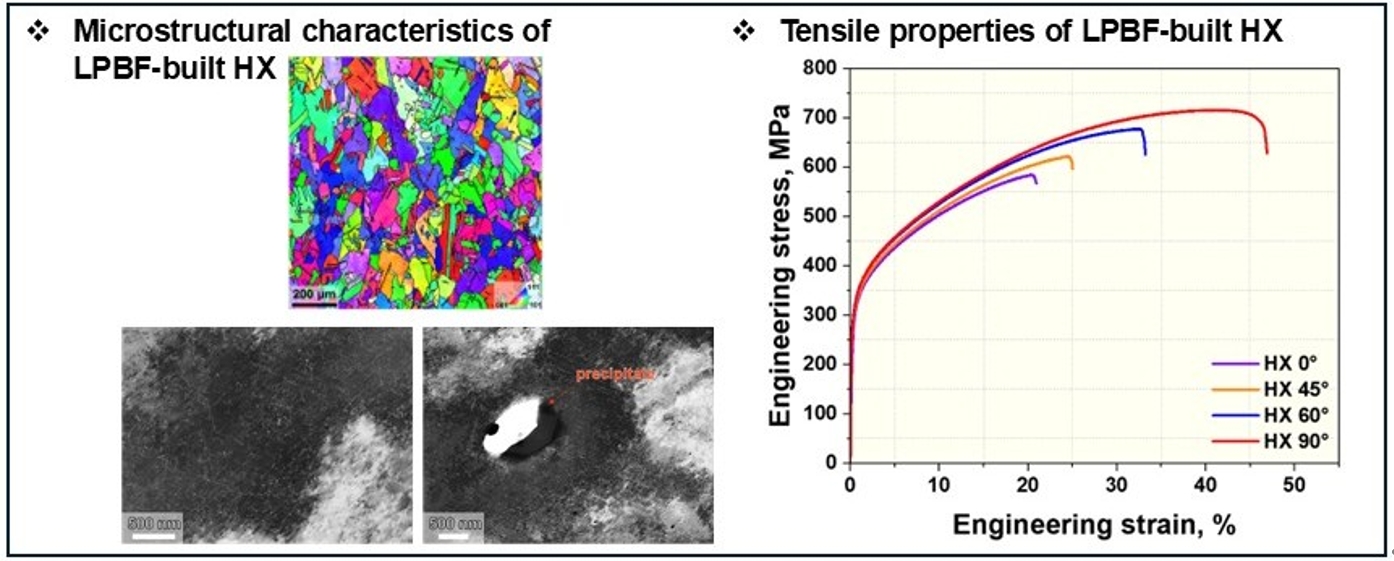

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):131-137. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00080

- 261 View

- 6 Download

-

Abstract

Abstract

PDF

PDF - In this study, the effect of build orientation on the mechanical properties of Hastelloy X fabricated by laser powder bed fusion (LPBF) process was investigated. Initial microstructural analysis revealed an equiaxed grain structure with random crystallographic orientation and annealing twins. Intragranular precipitates identified as Cr-rich M23C6 and Mo-rich M6C carbides were observed, along with a dense dislocation network and localized dislocation accumulation around the carbides. Mechanical testing showed negligible variation in yield strength with respect to build orientation; however, both ultimate tensile strength and elongation exhibited a clear increasing trend with higher build angles. Notably, the specimen built at 90° exhibited approximately 22% higher tensile strength and more than twice the elongation compared to the 0° specimen.

- [English]

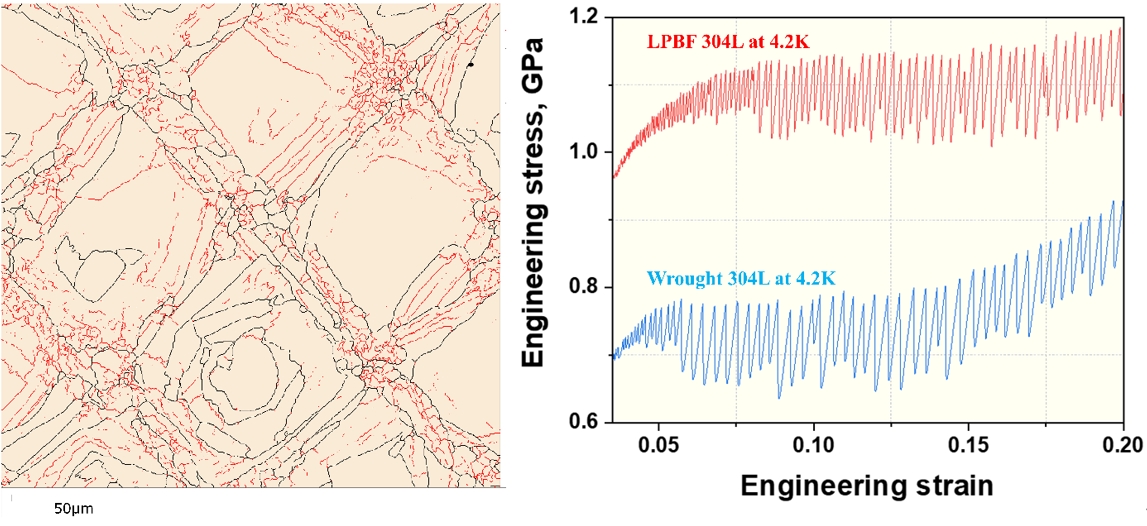

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 317 View

- 21 Download

-

Abstract

Abstract

PDF

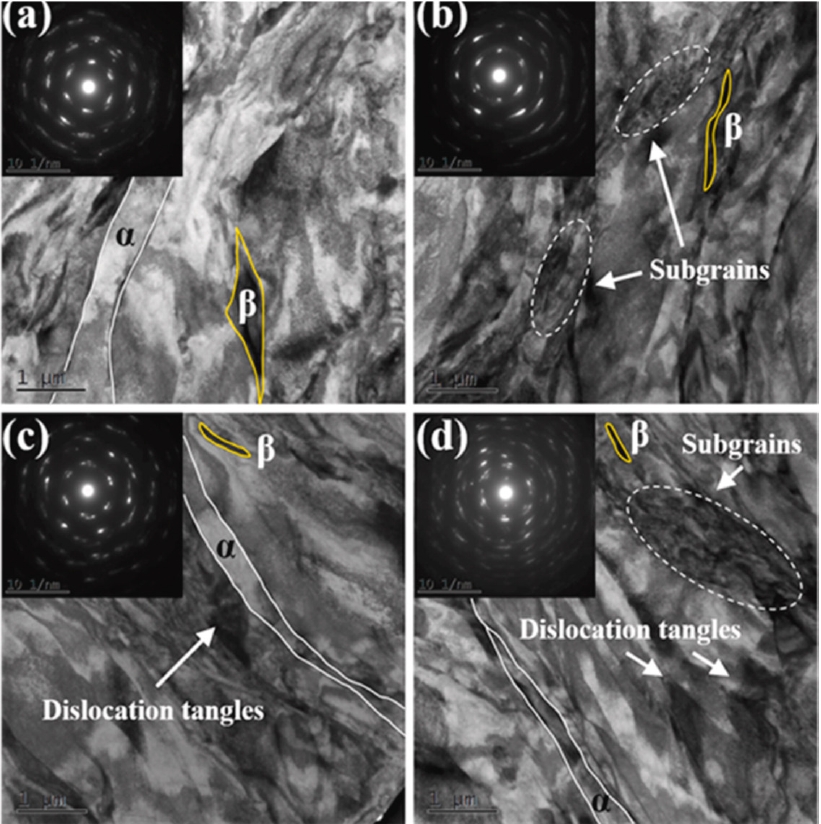

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

- [English]

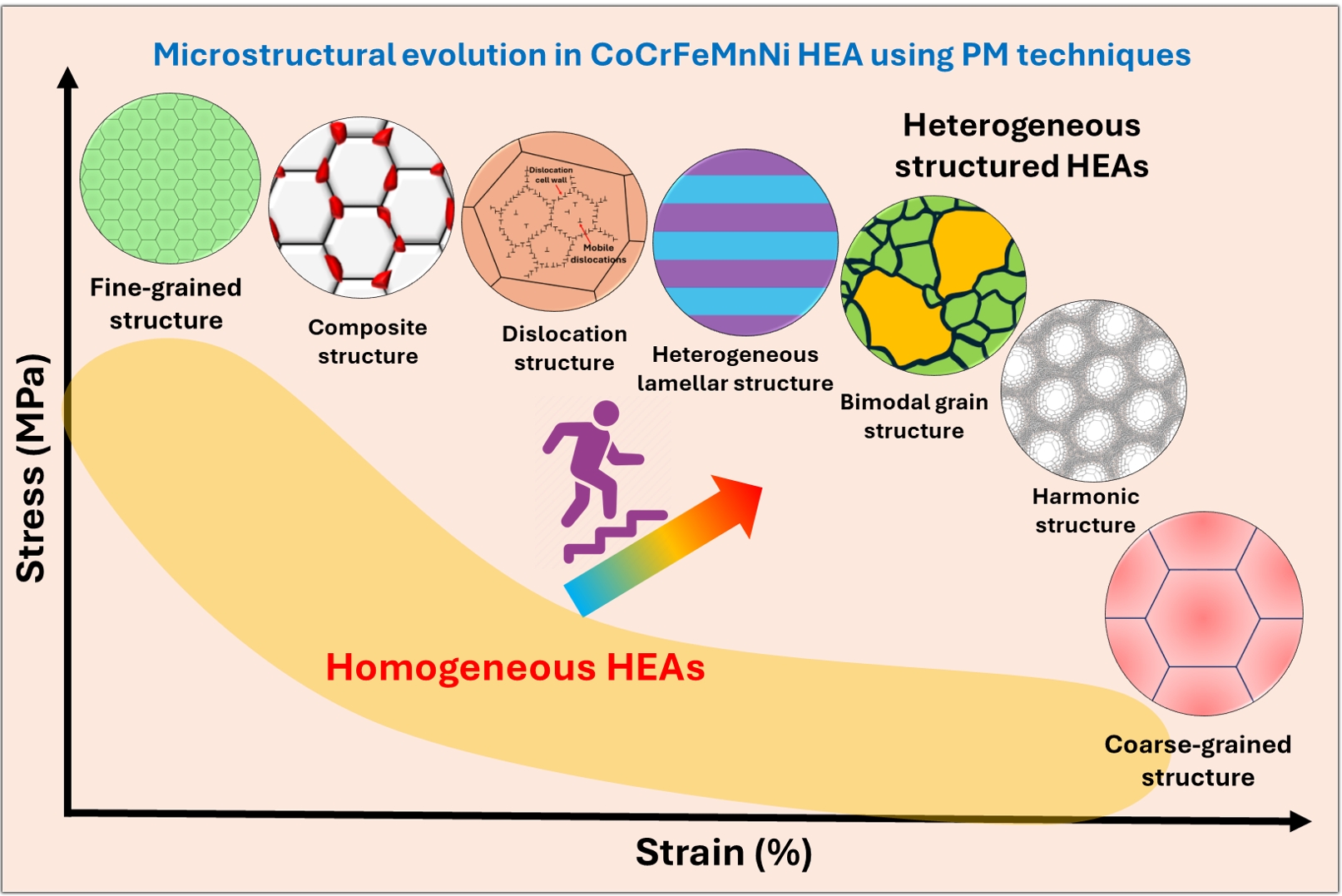

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 480 View

- 30 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- [English]

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

- J Powder Mater. 2024;31(5):365-373. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00213

- 709 View

- 35 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - This review examines the microstructural and mechanical properties of a Ti-6Al-4V alloy produced by wrought processing and powder metallurgy (PM), specifically laser powder bed fusion (LPBF) and hot isostatic pressing. Wrought methods, such as forging and rolling, create equiaxed alpha (α) and beta (β) grain structures with balanced properties, which are ideal for fatigue resistance. In contrast, PM methods, particularly LPBF, often yield a martensitic α′ structure with high microhardness, enabling complex geometries but requiring post-processing to improve its properties and reduce stress. The study evaluated the effects of processing parameters on grain size, phase distribution, and material characteristics, guiding the choice of fabrication techniques for optimizing Ti-6Al-4V performance in aerospace, biomedical, and automotive applications. The analysis emphasizes tailored processing to meet advanced engineering demands.

-

Citations

Citations to this article as recorded by- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025;[Epub] CrossRef

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

- [Korean]

- Fabrication of 3D Aligned h-BN based Polymer Composites with Enhanced Mechanical Properties for Battery Housing

- Kiho Song, Hyunseung Song, Sang In Lee, Changui Ahn

- J Powder Mater. 2024;31(4):329-335. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00220

- 687 View

- 24 Download

-

Abstract

Abstract

PDF

PDF Supplementary Material

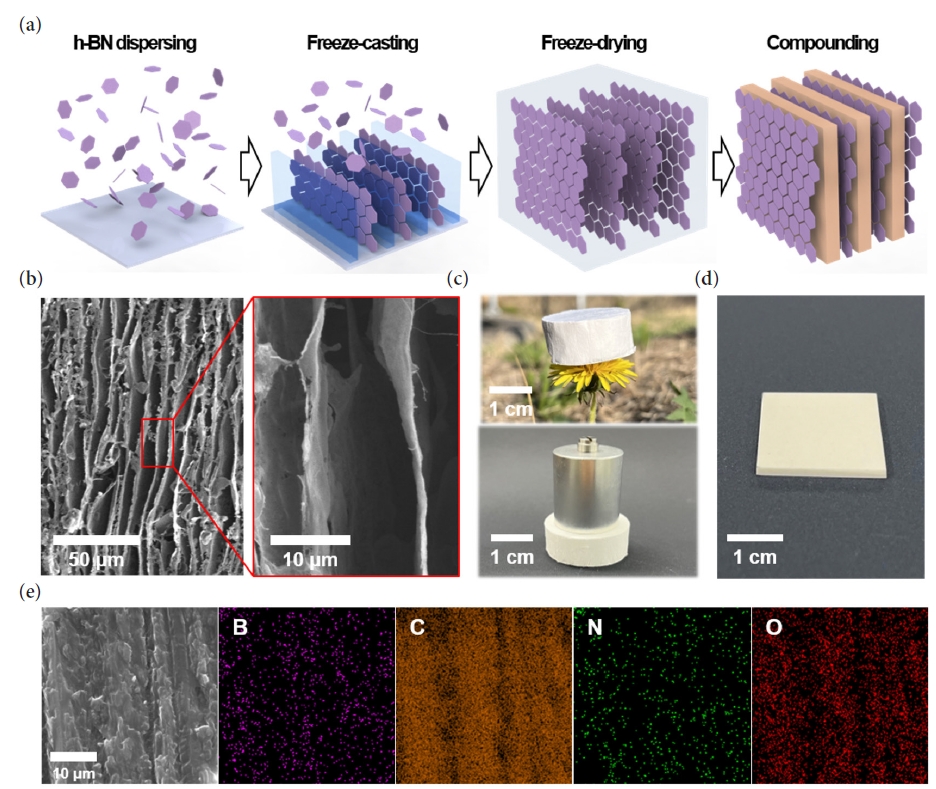

Supplementary Material - As the demand for electric vehicles increases, the stability of batteries has become one of the most significant issues. The battery housing, which protects the battery from external stimuli such as vibration, shock, and heat, is the crucial element in resolving safety problems. Conventional metal battery housings are being converted into polymer composites due to their lightweight and improved corrosion resistance to moisture. The transition to polymer composites requires high mechanical strength, electrical insulation, and thermal stability. In this paper, we proposes a high-strength nanocomposite made by infiltrating epoxy into a 3D aligned h-BN structure. The developed 3D aligned h-BN/epoxy composite not only exhibits a high compressive strength (108 MPa) but also demonstrates excellent electrical insulation and thermal stability, with a stable electrical resistivity at 200 °C and a low thermal expansion coefficient (11.46ⅹppm/℃), respectively.

- [English]

- Investigation of the Thermal-to-Electrical Properties of Transition Metal-Sb Alloys Synthesized for Thermoelectric Applications

- Jong Min Park, Seungki Jo, Sooho Jung, Jinhee Bae, Linh Ba Vu, Kwi-Il Park, Kyung Tae Kim

- J Powder Mater. 2024;31(3):236-242. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00031

- 824 View

- 41 Download

- 2 Citations

-

Abstract

Abstract

PDF

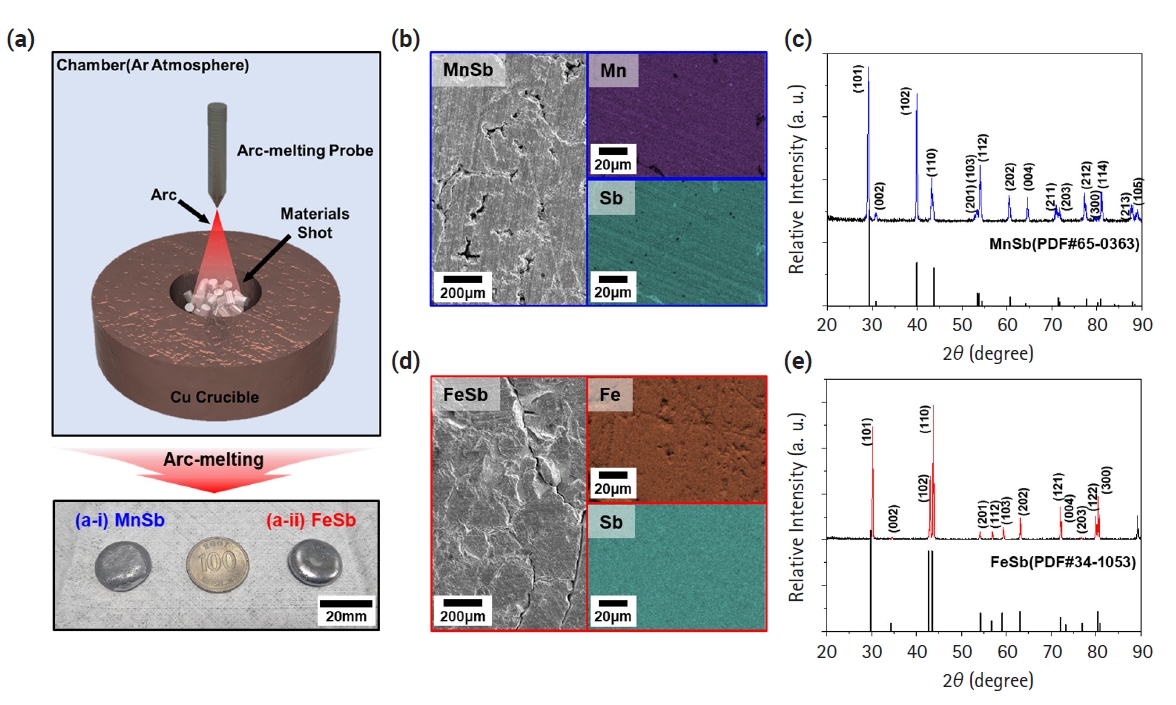

PDF - The development of thermoelectric (TE) materials to replace Bi2Te3 alloys is emerging as a hot issue with the potential for wider practical applications. In particular, layered Zintl-phase materials, which can appropriately control carrier and phonon transport behaviors, are being considered as promising candidates. However, limited data have been reported on the thermoelectric properties of metal-Sb materials that can be transformed into layered materials through the insertion of cations. In this study, we synthesized FeSb and MnSb, which are used as base materials for advanced thermoelectric materials. They were confirmed as single-phase materials by analyzing X-ray diffraction patterns. Based on electrical conductivity, the Seebeck coefficient, and thermal conductivity of both materials characterized as a function of temperature, the zT values of MnSb and FeSb were calculated to be 0.00119 and 0.00026, respectively. These properties provide a fundamental data for developing layered Zintl-phase materials with alkali/alkaline earth metal insertions.

-

Citations

Citations to this article as recorded by- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

Jong Min Park, Seungki Jo, Soo-ho Jung, Jinhee Bae, Linh Ba Vu, Jihun Yu, Kyung Tae Kim

Materials Letters.2025; 381: 137796. CrossRef - Highly deformable and hierarchical 3D composite sponge for versatile thermoelectric energy conversion

Jong Min Park, Changyeon Baek, Min-Ku Lee, Nagamalleswara Rao Alluri, Gyoung-Ja Lee, Kyung Tae Kim, Kwi-Il Park

Applied Surface Science.2025; 692: 162730. CrossRef

- Improving thermoelectric properties of CuMnSb alloys via strategic alloying with magnetic MnSb and Cu

- [English]

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

- Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

- J Powder Mater. 2024;31(1):8-15. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.8

- 2,676 View

- 125 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF The emergence of ferrous-medium entropy alloys (FeMEAs) with excellent tensile properties represents a potential direction for designing alloys based on metastable engineering. In this study, an FeMEA is successfully fabricated using laser powder bed fusion (LPBF), a metal additive manufacturing technology. Tensile tests are conducted on the LPBF-processed FeMEA at room temperature and cryogenic temperatures (77 K). At 77 K, the LPBF-processed FeMEA exhibits high yield strength and excellent ultimate tensile strength through active deformation-induced martensitic transformation. Furthermore, due to the low stability of the face-centered cubic (FCC) phase of the LPBF-processed FeMEA based on nano-scale solute heterogeneity, stress-induced martensitic transformation occurs, accompanied by the appearance of a yield point phenomenon during cryogenic tensile deformation. This study elucidates the origin of the yield point phenomenon and deformation behavior of the FeMEA at 77 K.

-

Citations

Citations to this article as recorded by- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

Journal of Powder Materials.2025; 32(2): 130. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Cryogenic tensile behavior of carbon-doped CoCrFeMnNi high-entropy alloys additively manufactured by laser powder bed fusion

Haeum Park, Hyeonseok Kwon, Kyung Tae Kim, Ji-Hun Yu, Jungho Choe, Hyokyung Sung, Hyoung Seop Kim, Jung Gi Kim, Jeong Min Park

Additive Manufacturing.2024; 86: 104223. CrossRef - Recent progress in high-entropy alloys for laser powder bed fusion: Design, processing, microstructure, and performance

Asker Jarlöv, Zhiguang Zhu, Weiming Ji, Shubo Gao, Zhiheng Hu, Priyanka Vivegananthan, Yujia Tian, Devesh Raju Kripalani, Haiyang Fan, Hang Li Seet, Changjun Han, Liming Tan, Feng Liu, Mui Ling Sharon Nai, Kun Zhou

Materials Science and Engineering: R: Reports.2024; 161: 100834. CrossRef

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- [Korean]

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

- J Powder Mater. 2023;30(5):409-414. Published online October 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.5.409

- 275 View

- 3 Download

-

Abstract

Abstract

PDF

PDF YSZ (Y2O3-stabilized zirconia)-based ceramics have excellent mechanical properties, such as high strength and wear resistance. In the application, YSZ is utilized in the bead mill, a fine-grinding process. YSZ-based parts, such as the rotor and pin, can be easily damaged by continuous application with high rpm in the bead mill process. In that case, adding WC particles improves the tribological and mechanical properties. YSZ-30 vol.% WC composite ceramics are manufactured via hot pressing under different pressures (10/30/60 MPa). The hot-pressed composite ceramics measure the physical properties, such as porosity and bulk density values. In addition, the phase formation of these composite ceramics is analyzed and discussed with those of physical properties. For the increased applied pressure of hot pressing, the tetragonality of YSZ and the crystallinity of WC are enhanced. The mechanical properties indicate an improved tendency with the increase in the applied pressure of hot pressing.

- [Korean]

- Fabrication of Polymer Composite with Enhanced Insulation and Mechanical Properties using Aluminum Borate Nanowhiskers

- Junhyeok Choi, Sangin Lee, Kiho Song, Taekyung Kim, Changui Ahn

- J Powder Mater. 2023;30(4):356-362. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.356

- 480 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Inorganic-organic composites find extensive application in various fields, including electronic devices and light-emitting diodes. Notably, encapsulation technologies are employed to shield electronic devices (such as printed circuit boards and batteries) from stress and moisture exposure while maintaining electrical insulation. Polymer composites can be used as encapsulation materials because of their controllable mechanical and electrical properties. In this study, we propose a polymer composite that provides good electrical insulation and enhanced mechanical properties. This is achieved by using aluminum borate nanowhiskers (ABOw), which are fabricated using a facile synthesis method. The ABOw fillers are created via a hydrothermal method using aluminum chloride and boric acid. We confirm that the synthesis occurs in various morphologies based on the molar ratio. Specifically, nanowhiskers are synthesized at a molar ratio of 1:3 and used as fillers in the composite. The fabricated ABOw/epoxy composites exhibit a 48.5% enhancement in mechanical properties, similar to those of pure epoxy, while maintaining good electrical insulation.

-

Citations

Citations to this article as recorded by- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

Kiho Song, Sang in Lee, Hyunseung Song, Changui Ahn

Journal of Powder Materials.2024; 31(6): 513. CrossRef

- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

- [English]

- Enhancing Electrical Properties of N-type Bismuth Telluride Alloys through Graphene Oxide Incorporation in Extrusion 3D Printing

- Jinhee Bae, Seungki Jo, Kyung Tae Kim

- J Powder Mater. 2023;30(4):318-323. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.318

- 546 View

- 7 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The thermoelectric effect, which converts waste heat into electricity, holds promise as a renewable energy technology. Recently, bismuth telluride (Bi2Te3)-based alloys are being recognized as important materials for practical applications in the temperature range from room temperature to 500 K. However, conventional sintering processes impose limitations on shape-changeable and tailorable Bi2Te3 materials. To overcome these issues, three-dimensional (3D) printing (additive manufacturing) is being adopted. Although some research results have been reported, relatively few studies on 3D printed thermoelectric materials are being carried out. In this study, we utilize extrusion 3D printing to manufacture n-type Bi1.7Sb0.3Te3 (N-BST). The ink is produced without using organic binders, which could negatively influence its thermoelectric properties. Furthermore, we introduce graphene oxide (GO) at the crystal interface to enhance the electrical properties. The formed N-BST composites exhibit significantly improved electrical conductivity and a higher Seebeck coefficient as the GO content increases. Therefore, we propose that the combination of the extrusion 3D printing process (Direct Ink Writing, DIW) and the incorporation of GO into N-BST offers a convenient and effective approach for achieving higher thermoelectric efficiency.

-

Citations

Citations to this article as recorded by- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

Linh Ba Vu, Soo-ho Jung, Jinhee Bae, Jong Min Park, Kyung Tae Kim, Injoon Son, Seungki Jo

journal of Korean Powder Metallurgy Institute.2024; 31(2): 119. CrossRef

- Exploring Thermoelectric Transport Properties and Band Parameters of n-Type Bi2-xSbxTe3 Compounds Using the Single Parabolic Band Model

- [Korean]

- Effect of Bulk Shape on Mechanical Properties of Ti-6Al-4V Alloy Manufactured by Laser Powder Bed Fusion

- Haeum Park, Yeon Woo Kim, Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Jung Gi Kim, Jeong Min Park

- J Powder Mater. 2023;30(2):140-145. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.140

- 1,379 View

- 20 Download

- 5 Citations

-

Abstract

Abstract

PDF

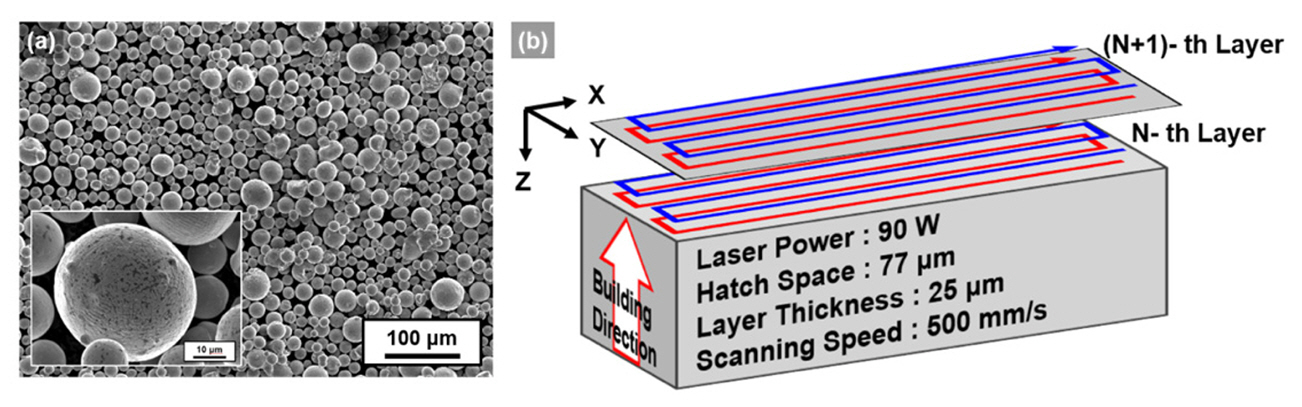

PDF Although the Ti–6Al–4V alloy has been used in the aircraft industry owing to its excellent mechanical properties and low density, the low formability of the alloy hinders broadening its applications. Recently, laser-powder bed fusion (L-PBF) has become a novel process for overcoming the limitations of the alloy (i.e., low formability), owing to the high degree of design freedom for the geometry of products having outstanding performance used in hightech applications. In this study, to investigate the effect of bulk shape on the microstructure and mechanical properties of L-PBFed Ti-6Al-4V alloys, two types of samples are fabricated using L-PBF: thick and thin samples. The thick sample exhibits lower strength and higher ductility than the thin sample owing to the larger grain size and lower residual dislocation density of the thick sample because of the heat input during the L-PBF process.

-

Citations

Citations to this article as recorded by- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef - Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

journal of Korean Powder Metallurgy Institute.2024; 31(1): 1. CrossRef - Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

journal of Korean Powder Metallurgy Institute.2024; 31(2): 137. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - High-speed manufacturing-driven strength-ductility improvement of H13 tool steel fabricated by selective laser melting

Yeon Woo Kim, Haeum Park, Young Seong Eom, Dong Gill Ahn, Kyung Tae Kim, Ji-hun Yu, Yoon Suk Choi, Jeong Min Park

Powder Metallurgy.2023; 66(5): 582. CrossRef

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

- [Korean]

- Comparison of Properties with Different Sintering Process of 3Y-TZP/WC Composites

- Min-Soo Nam, Jae-Hyung Choi, Sahn Nahm, Seongwon Kim

- J Powder Mater. 2022;29(5):424-431. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.424

- 421 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF 3Y-TZP ceramics obtained by doping 3 mol.% of Y2O3 to ZrO2 to stabilize the phase transition are widely used in the engineering ceramic industry due to their excellent mechanical properties such as high strength, fracture toughness, and wear resistance. An additional increase in mechanical properties is possible by manufacturing a composite in which a high-hardness material such as oxide or carbide is added to the 3Y-TZP matrix. In this study, composite powder was prepared by dispersing a designated percentage of WC in the 3Y-TZP matrix, and the results were compared after manufacturing the composite using the different processes of spark plasma sintering and HP. The difference between the densification behavior and porosity with the process mechanism was investigated. The correlation between the process conditions and phase formation was examined based on the crystalline phase formation behavior. Changes to the microstructure according to the process conditions were compared using field-emission scanning electron microscopy. The toughness-strengthening mechanism of the composite with densification and phase formation was also investigated.

-

Citations

Citations to this article as recorded by- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

journal of Korean Powder Metallurgy Institute.2023; 30(5): 409. CrossRef

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- [Korean]

- Developing Continuous Stabilization Process for Textile-Grade PAN Fiber-Based Carbon Fiber Using UV Irradiation

- Joon Ha Moon, Honggyu Seong, Jiseon Yoo, Se Youn Cho, Jaewon Choi

- J Powder Mater. 2022;29(5):418-423. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.418

- 428 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Carbon fibers (CFs) are considered promising composite materials for various applications. However, the high cost of CFs (as much as $26 per kg) limits their practical use in the automobile and energy industries. In this study, we developed a continuous stabilization process for manufacturing low-cost CFs. We employed a textile-grade polyacrylonitrile (PAN) fiber as a low-cost precursor and UV irradiation technique to shorten the thermal stabilization time. We confirmed that UV irradiation on the textile-grade PAN fibers could lower the initial thermal stabilization temperature and also lead to a higher reaction. These resulted in a shorter overall stabilization time and enhancement of the tensile properties of textilegrade PAN-based CFs. Our study found that only 70 min of stabilization time with UV irradiation was required to prepare textile-grade PAN-based low-cost CFs with a tensile strength of 2.37 ± 0.22GPa and tensile modulus of 249 ± 5 GPa.

- [Korean]

- Evaluation of Mechanical Properties and Microstructure Depending on Sintering Heating Rate of IN 939W Alloy

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):399-410. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.399

- 990 View

- 20 Download

-

Abstract

Abstract

PDF

PDF Changes in the mechanical properties and microstructure of an IN 939 W alloy according to the sintering heating rate were evaluated. IN 939 W alloy samples were fabricated by spark plasma sintering. The phase fraction, number density, and mean radius of the IN 939W alloy were calculated using a thermodynamic calculation. A universal testing machine and micro-Vickers hardness tester were employed to confirm the mechanical properties of the IN 939W alloy. X-ray diffraction, optical microscopy, field-emission scanning electron microscopy, Cs-corrected-field emission transmission electron microscopy, and energy dispersive X-ray spectrometry were used to evaluate the microstructure of the alloy. The rapid sintering heating rate resulted in a slightly dispersed γ' phase and chromium oxide. It also suppressed the precipitation of the η phase. These helped to reinforce the mechanical properties.

TOP

kpmi

kpmi

First

First Prev

Prev